Mixed-phase mesoporous titanium dioxide and preparation method thereof, and treatment method for removing arsenic-containing organic pollutants under photocatalysis of mixed-phase mesoporous titanium dioxide

A technology of mesoporous titanium dioxide and organic pollutants, applied in the field of water treatment, can solve problems such as ambiguous DMA mechanism, achieve the effects of improving photocatalytic activity, efficient oxidation degradation, and simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068]This example provides a miscible mesoporous titanium dioxide, the preparation method of which is the solvent evaporation-induced self-assembly method, the steps are: using P123 as a template agent, dissolving it in an appropriate amount of ethanol, and adding 1.4 g of concentrated Hydrochloric acid and 0.46g of sulfuric acid were stirred at room temperature for 3h. Add 3 g of isopropyl titanate TIPO to the mixture, and stir for 20 h to ensure that TIPO is fully hydrolyzed and polymerized. Then the solution was dried in a vacuum oven at 40° C. and 100° C. for two days respectively. The obtained sample was fired in a nitrogen atmosphere in a tube furnace for 3 hours, and then fired in a muffle furnace at 450° C. for 6 hours, and the finally obtained sample was miscible mesoporous titanium dioxide.

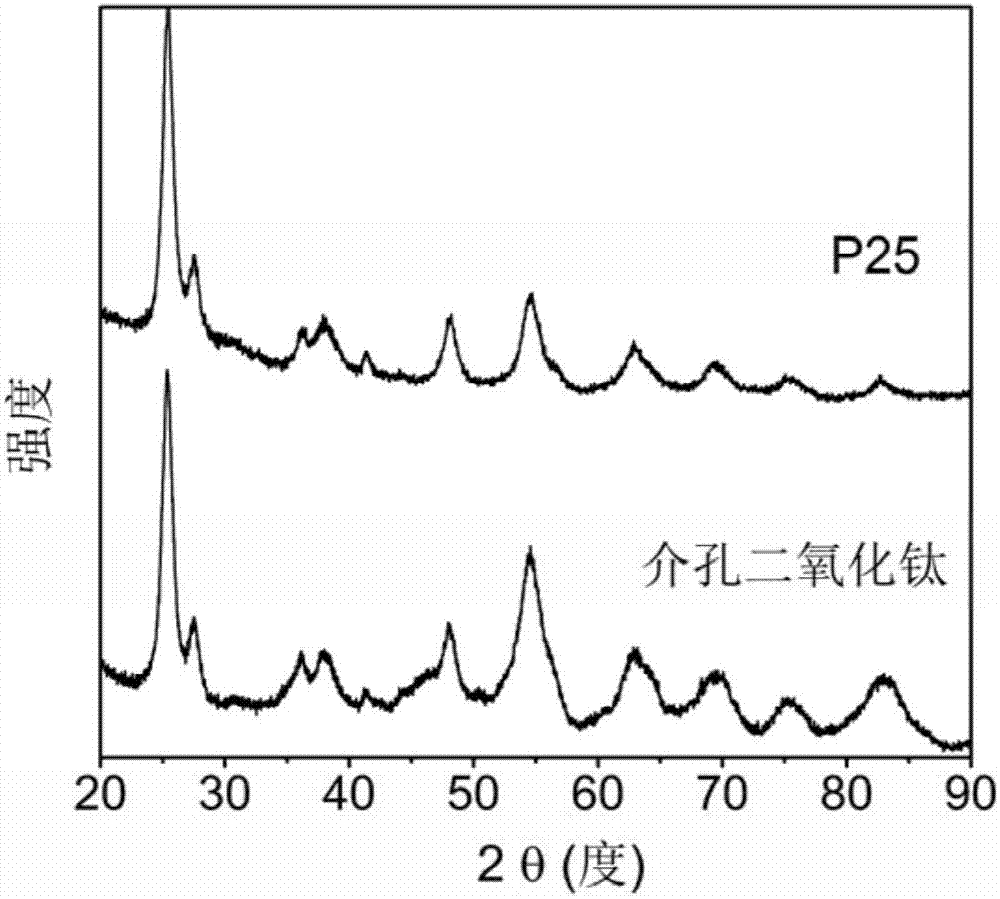

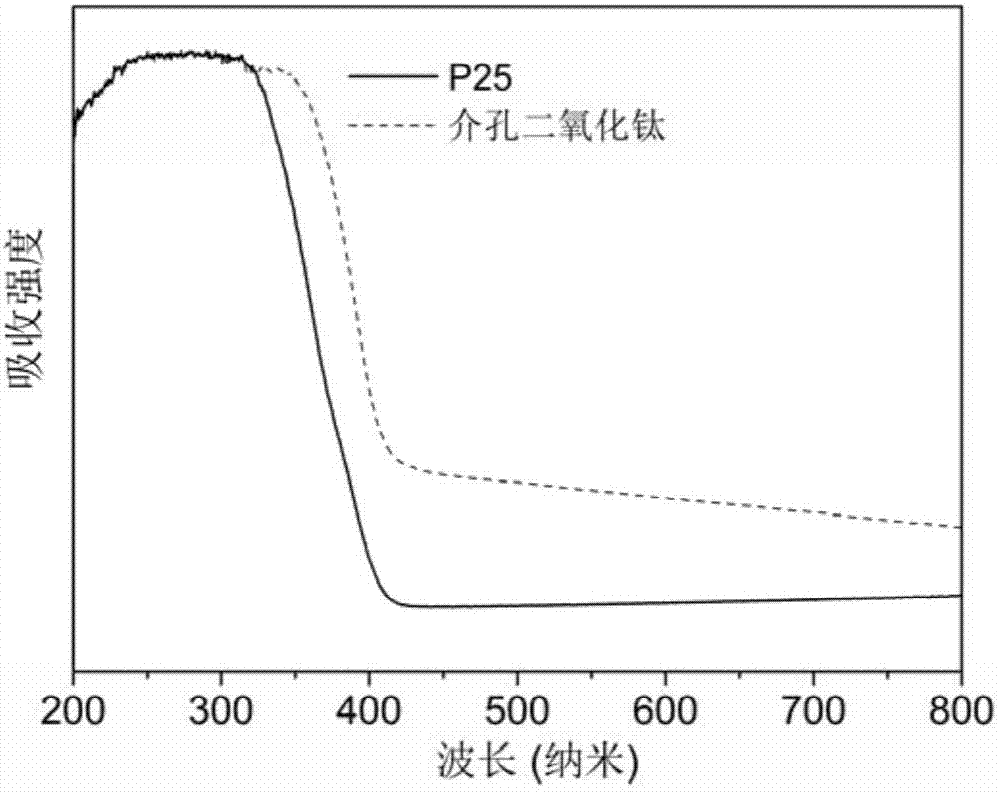

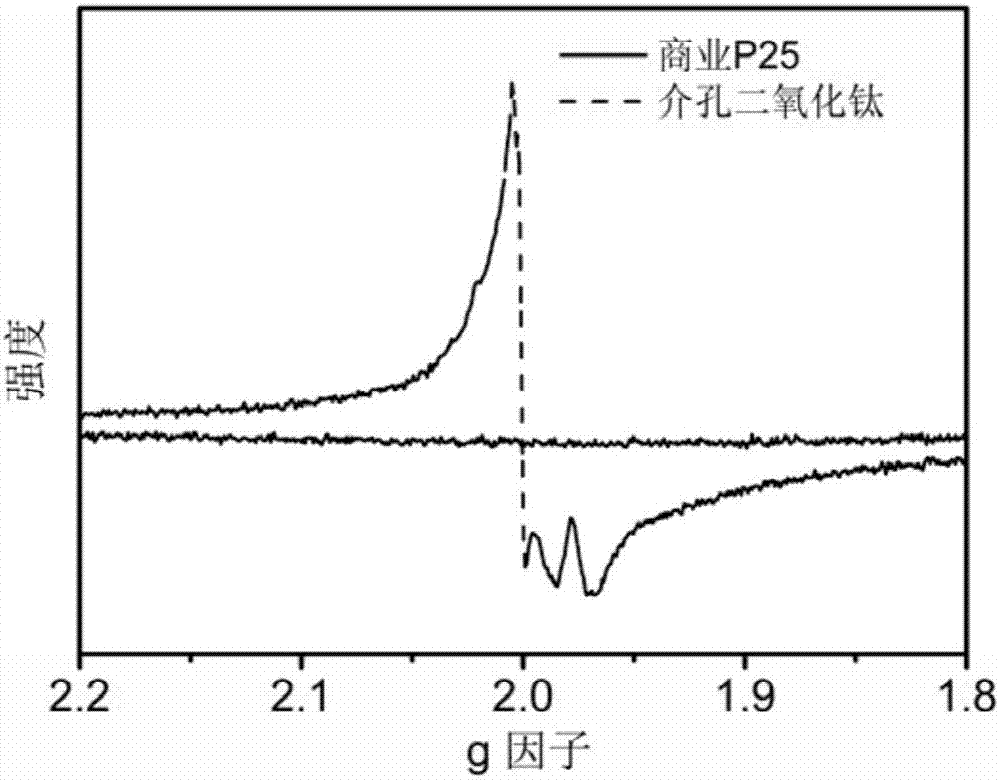

[0069] Characterization of mesoporous titania: Through a series of characterizations of the mesoporous titania obtained in Example 1 and the P25 material in Comparative Exampl...

Embodiment 2

[0076] During the experiment, an appropriate amount of mesoporous titanium dioxide was added to 100ml of DMA solution with an initial concentration of 200μg / L, the solution was first placed on a magnetic stirrer, and adsorbed for 1h under dark conditions, and then the solution was transferred to a photocatalytic In the reactor, the photocatalytic reaction was carried out under the irradiation of xenon lamp. Under the same experimental conditions, the mesoporous titanium dioxide was replaced with the same dosage of commercial P25, and a comparative experiment was carried out. By measuring the total arsenic concentration in the solution during the reaction, the effects of photocatalytic degradation of DMA by mesoporous titania and P25 were compared. The change curve of arsenic concentration with time is shown in Figure 5 , the results show that under the same conditions, the adsorption capacity of mesoporous titanium dioxide to DMA is about 43% higher than that of P25 in Compa...

Embodiment 3

[0078] During the experiment, different amounts of mesoporous titanium dioxide were added to 100 ml of DMA solution with an initial concentration of 200 μg / L, the solution was first placed on a magnetic stirrer, and adsorbed for 1 h under dark conditions, and then the solution was transferred to In the photocatalytic reactor, the photocatalytic reaction is carried out under the irradiation of xenon lamp. The optimal dosage of mesoporous titania was determined by measuring the change of arsenic concentration in the process of photocatalytic degradation of DMA under different dosages of mesoporous titania. The results show that the photocatalytic effect is the best when the dosage of mesoporous titanium dioxide is 0.8g / L-1g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com