High-stability fish oil emulsion capable of improving glycometabolism and preparation method of high-stability fish oil emulsion

A high-stability, sugar-metabolizing technology, applied in the direction of edible oil/fat ingredients, etc., to achieve the effect of easy portability, prevention and auxiliary improvement of diabetes symptoms, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、5

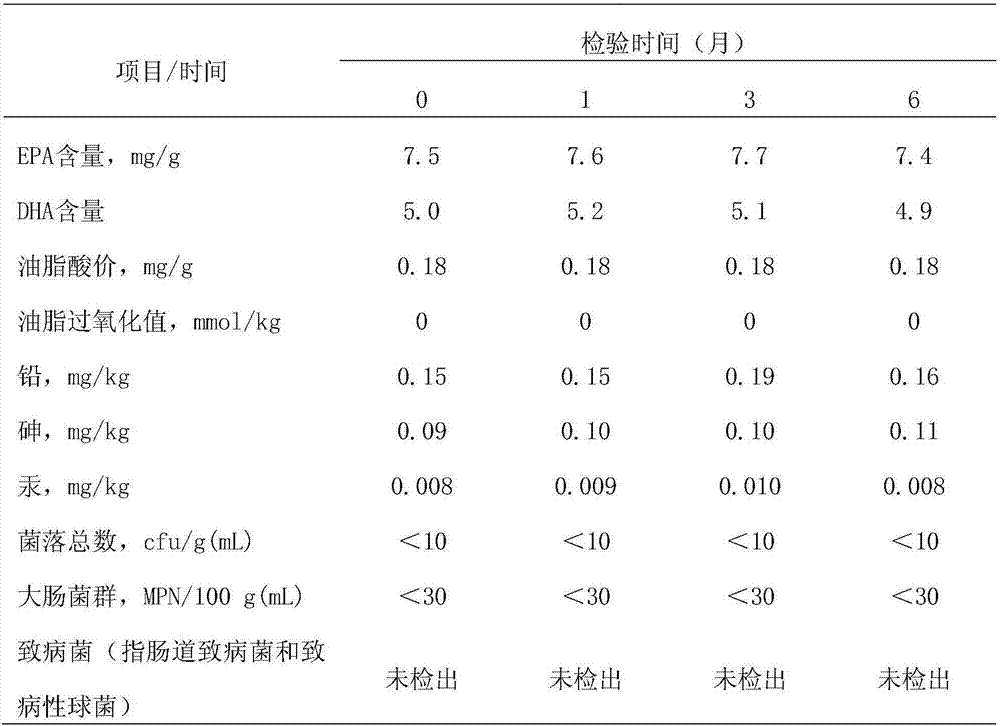

[0044] Embodiment 1, 5% fish oil emulsion and its preparation

[0045] 1# Add water 912kg, sodium caseinate (emulsifier) 5kg, sodium carboxymethyl cellulose (emulsion stabilizer) 1kg, sodium ascorbate 1kg (antioxidant), 20kg of isomaltooligosaccharides, vitamin B1 1.5kg, vitamin B1 in the batching tank B6 1.5kg, vitamin B12 1kg, whey protein 0.8kg, magnesium gluconate 0.2kg, dissolved at 40°C to obtain the water phase.

[0046] 2 # Add 50kg of triglyceride-type fish oil, 1kg of vitamin A, 1kg of vitamin D3, and 4kg of natural sweet orange essence into the batching tank and mix evenly to obtain the oil phase;

[0047] Will 1 # The material in the batching tank is pumped into 2 under the protection of nitrogen filling # The batching tank is cut for 0.5h under the conditions of rotating speed of 3000r / min and vacuum pressure of -0.10MPa, and then the material is passed through a high-pressure homogenizer at 50MPa, homogenized for 2min, sterilized, and aseptically filled. A ...

Embodiment 2、10

[0048] Embodiment 2, 10% fish oil emulsion and its preparation

[0049] 1 # Add water 861kg, sodium caseinate (emulsifier) 6kg, sodium carboxymethyl cellulose (emulsion stabilizer) 1kg, sodium ascorbate 1kg (antioxidant), oligosaccharide 19.8kg, vitamin B1 1kg, vitamin B1 in the batching tank 1kg of B6, 1kg of vitamin B12, 1kg of soybean protein isolate, and 0.2kg of magnesium gluconate were dissolved at 40°C to obtain an aqueous phase.

[0050] 2 # Add 100kg of triglyceride-type fish oil, 1kg of vitamin A, 1kg of vitamin D3, and 5kg of natural sweet orange essence into the batching tank and mix evenly to obtain the oil phase;

[0051] Will 1 # The material in the batching tank is pumped into 2 under the protection of nitrogen filling # The batching tank is cut for 0.5h under the conditions of rotating speed of 3000r / min and vacuum pressure of -0.10MPa, and then the material is passed through a high-pressure homogenizer at 50MPa, homogenized for 2min, sterilized, and ase...

Embodiment 3、16

[0052] Embodiment 3, 16% fish oil emulsion and its preparation

[0053] 1 # Add water 801kg, sucrose fatty acid ester (emulsifier) 6kg, xanthan gum (emulsion stabilizer) 4kg, sodium ascorbate (antioxidant) 1kg, xylitol (carbohydrate) 20kg, soybean protein (protein) 0.8 in the batching tank kg, 0.2kg of zinc gluconate, dissolved at 50°C to obtain an oil phase.

[0054] 2 # Add 160 kg of ethyl ester type fish oil, 1 kg of vitamin A, 1 kg of vitamin D3, and 5 kg of natural lemon essence into the batching tank and mix evenly to obtain an oil phase.

[0055] Will 1 # The material in the batching tank is pumped into 2 under the protection of nitrogen filling # The batching tank is sheared for 1 hour under the conditions of a rotation speed of 2000r / min and a vacuum pressure of -0.08MPa, and then the material is passed through a high-pressure homogenizer at 30MPa, homogenized for 4 minutes, sterilized, and aseptically filled. A highly stable fish oil emulsion containing 16% fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com