Composite metal oxide with hollow urchin-like structure, and preparation method and application thereof

A composite metal, sea urchin-like technology, applied in the direction of nickel oxide/nickel hydroxide, hybrid capacitor electrodes, material resistance, etc., can solve the problems of not meeting the accuracy requirements of hydrogen sulfide, insufficient sensitivity, high working temperature, etc., and achieve contact resistance Value and specific capacitance value performance improvement, good repeatability, and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a composite metal oxide with a hollow sea urchin-like structure provided by an embodiment of the present invention includes: uniformly mixing a metal element-containing compound and a reducing agent in a solvent, The reaction under the condition of ~200°C does not exceed 50h, and then the obtained product is annealed under the condition of 0°C-450°C to obtain the composite metal oxide having a hollow sea urchin-like structure.

[0029] In some preferred embodiments, the preparation method includes: mixing the metal element-containing compound and the reducing agent in a solvent, and making the formed mixed reaction liquid under pressure of 1-30Pa (preferably 5-20Pa, especially Preferably 10~15Pa), the temperature is 25~200 ℃ (preferably 120~180 ℃, especially preferably 150~170 ℃) under the conditions of continuous reaction 1~10h (preferably 2~8h, especially preferably 3~5h ), and annealed at 100-450°C (preferably 200-420°C, especially preferably 3...

Embodiment 1

[0082] Example 1 The preparation process of the composite metal oxide having a hollow sea urchin-like structure in this example includes:

[0083]Pour nickel chloride with a molar ratio of 6:4 (concentration of 1M nickel chloride solution, 1.35ml in total) and cobalt chloride into a beaker filled with 75mL of deionized water. Stir on a magnetic stirrer. After dissolving, add 3g of urea and continue to stir for 1h to mix evenly. Then pour the mixed solution into a 150ml hot water reactor and react at 180°C for 4 hours. After cooling down to room temperature naturally, add water / ethanol repeatedly washed several times and centrifuged, the product was placed in a tubular heating furnace and annealed at 400° C. for 3 hours to obtain a composite metal oxide with a hollow sea urchin-like structure.

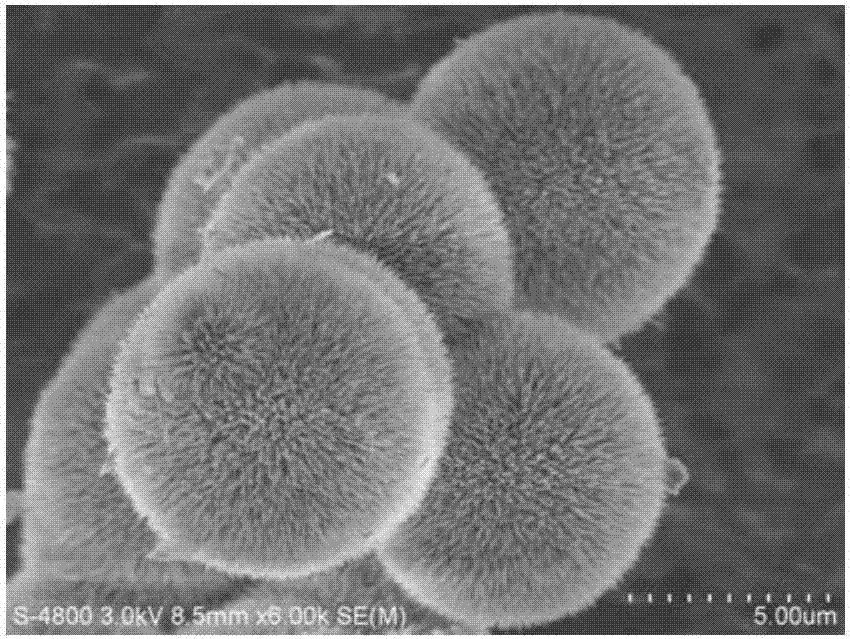

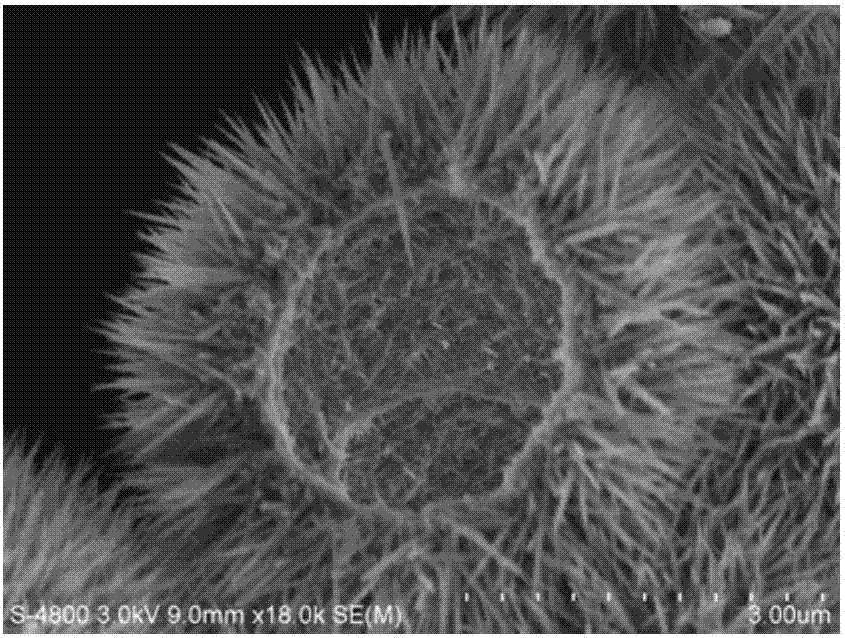

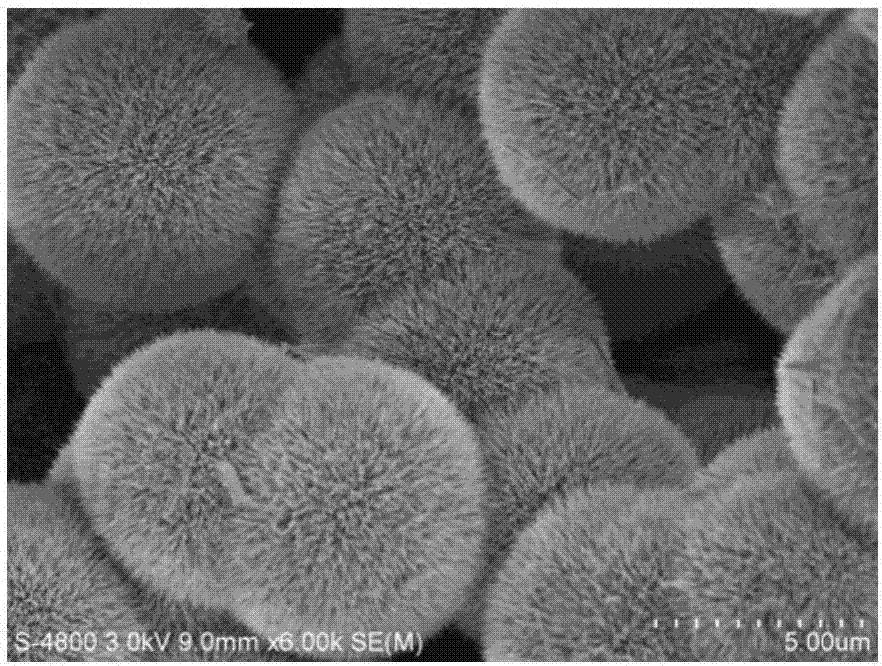

[0084] see Figure 1a-Figure 1c It is the SEM image of the composite metal oxide with a hollow sea urchin-like structure prepared in this example. And the specific surface area and c...

Embodiment 2

[0093] Embodiment 2: the nickel chloride (concentration is the nickel chloride solution of 1M, totally 1.35ml) and the manganese chloride that the molar ratio is 6:4 are poured in the beaker that 75mL deionized water is housed, in the beaker that has heating function Stir on a magnetic stirrer at (30°C), add 3g of urea after dissolving and continue to stir for 1h to mix evenly, then pour the mixed solution into a 150ml hot water reactor and react at 180°C for 4 hours, then cool down to room temperature naturally After that, it was repeatedly washed with water / ethanol and centrifuged, and the product was placed in a tubular heating furnace and annealed at 400°C for 3 hours to obtain a composite metal oxide with a hollow sea urchin-like structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com