Ethyl acetate synthesis method utilizing membrane separation dehydration

A technology of ethyl acetate and synthesis method, which is applied in the direction of semi-permeable membrane separation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of poor water-carrying ability and high energy consumption of reflux ester, and achieve reduction of reflux flow and energy consumption. The effect of low consumption, guaranteed yield and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

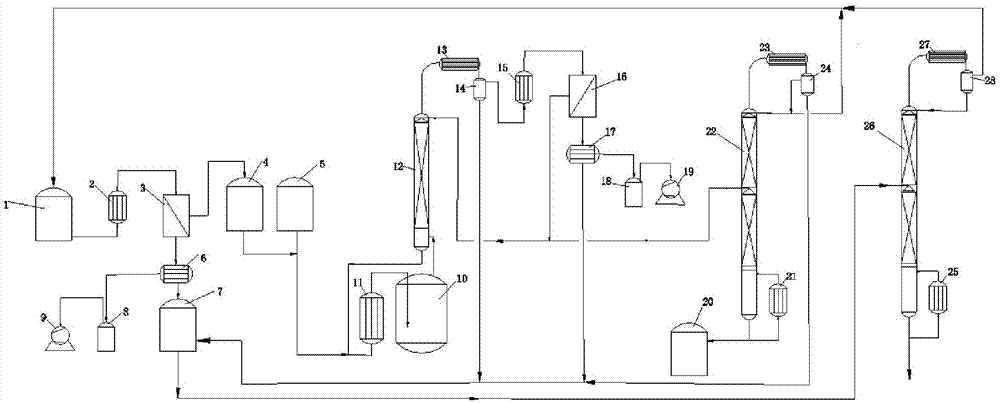

Image

Examples

Embodiment 2

[0032] Crude ethanol with a water content of 15%, the feed rate is controlled at 600L / h, heated and vaporized by the raw material evaporator 2, the temperature of the hot steam is controlled at 120°C, and the steam enters the raw material pervaporation water-permeable membrane module 3, and the pressure of the feed liquid is controlled to 0.3MPa. The side pressure is 1000Pa, the dehydrated ethanol separated by the membrane has a water content of 0.33%, and enters the dehydrated ester alcohol tank 4, while the water permeated through the raw material pervaporation water-permeable membrane module 3 is collected and discharged by vacuum condensation in the condenser 6, and the water content is 99.51%.

[0033] The dehydrated ethanol in the dehydrated ester alcohol tank 4 and the acetic acid in the acetic acid tank 5 are fed into the esterification tank 10 after being reboiled continuously through the esterification reboiler 11 at a flow rate of 550 L / h and 540 L / h respectively, and...

Embodiment 3

[0038] The water content is 8% crude ethanol, the feed rate is controlled to 800L / h, and the raw material evaporator 2 is heated to evaporate and vaporize, the temperature of the hot steam is controlled to be 110°C, and it enters the raw material pervaporation water-permeable membrane module 3, and the measured pressure of the feed liquid is controlled to 0.17MPa. The side pressure is 1000Pa, the water content of dehydrated ethanol after membrane separation is 0.22%, and enters the dehydrated ester alcohol tank 4, and the water permeated by the raw material pervaporation water-permeable membrane module 3 is collected and discharged by vacuum condensation in the condenser 6, and the water content is 99.30%.

[0039] The dehydrated ethanol in the dehydration ester alcohol tank 4 and the acetic acid in the acetic acid tank 5 are fed into the esterification kettle 10 after being reboiled continuously through the esterification reboiler 11 at a flow rate of 700L / h and 695L / h respecti...

Embodiment 4

[0044] Crude ethanol with a water content of 5%, the feed rate is controlled at 900L / h, heated and evaporated by the raw material evaporator 2, the temperature of the hot steam is controlled at 105°C, and the steam enters the raw material pervaporation water-permeable membrane module 3, the pressure of the feed liquid is controlled to 0.13MPa, and the permeable The side pressure is 1000Pa, and the dehydrated ethanol has a water content of 0.17% after membrane separation, and enters the dehydrated ester alcohol tank 4, while the water permeated through the raw material pervaporation water-permeable membrane module 3 is collected and discharged by vacuum condensation in the condenser 6, with a water content of 99.32%.

[0045] The dehydrated ethanol in the dehydration ester alcohol tank 4 and the acetic acid in the acetic acid tank 5 are fed into the esterification tank 10 after being reboiled continuously through the esterification reboiler 11 at a flow rate of 800 L / h and 795 L / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com