Method for preparing 2-methyltetrahydrofuran by taking 4-pentene-1-ol as raw material in one step through high-efficiency catalyst

A methyltetrahydrofuran, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of poor thermal stability and oxidation resistance, easy swelling Difficult to continuously catalyze the reaction, low specific surface area, etc., to achieve the effect of easy recovery, rapid and safe separation of catalyst, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] (1) Preparation of ferroferromagnetic nanoparticles wrapped in silica gel:

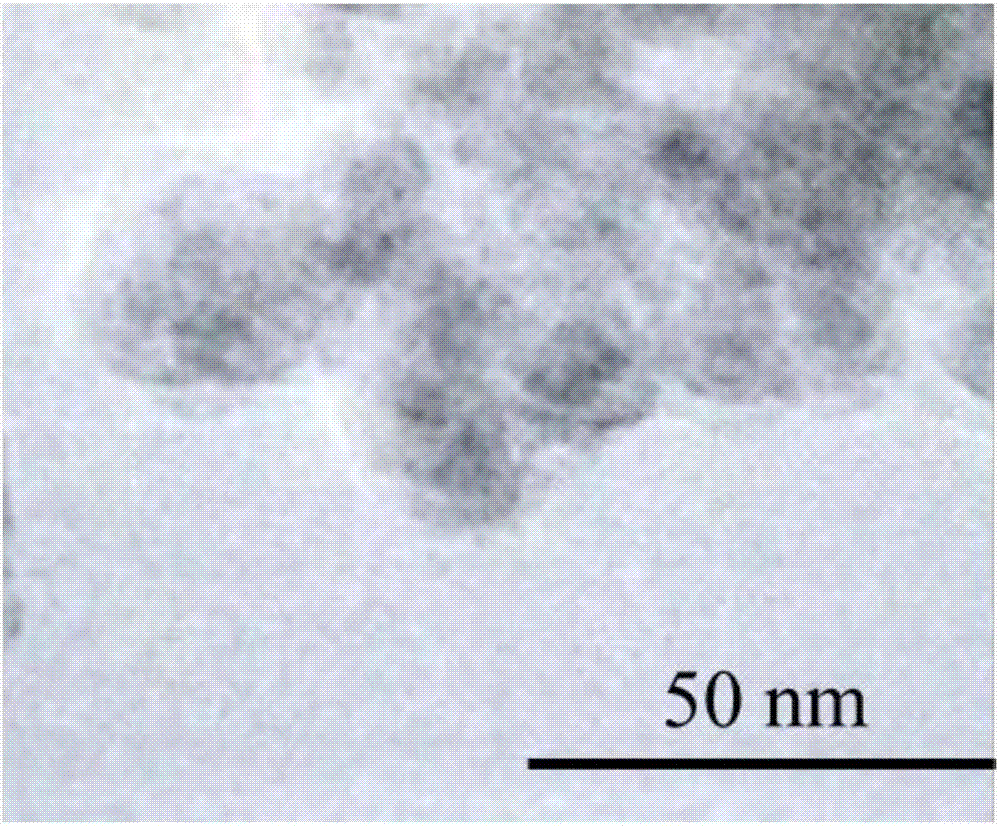

[0036] Take 11.0g of ferric chloride and 4.0g of ferrous chloride and dissolve them in 250mL of deionized water under nitrogen atmosphere at 85°C with vigorous stirring, then adjust the pH value to 9 with concentrated ammonia water, keep stirring for 4h, and wash the precipitate with deionized water Wash until neutral to obtain black ferric oxide particles (8-12nm). Take 2.0g of the above iron ferric oxide particles and ultrasonicate at room temperature for 30min, disperse in 400mL ethanol, then add 12mL concentrated ammonia water and 4.0mL tetraethyl orthosilicate, stir and react for 24h, the black precipitate is magnetically separated and washed with ethanol several times Vacuum drying after neutrality, obtained silica gel-wrapped ferroferric oxide magnetic nanoparticles (20-30nm), such as figure 1 shown.

[0037] (2) Preparation of 3-azidopropyltriethyloxysilane:

[0038] In a 150mL round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com