Nanometer lignocellulose/montmorillonite composite material and preparation and application thereof

A technology of lignocellulose and composite materials, which can be applied in other chemical processes, water/sewage treatment, adsorbed water/sewage treatment, etc., and can solve the problems of large investment, high operating cost, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The present embodiment provides a kind of preparation method of nanometer lignocellulose, it comprises the following steps:

[0095] Weigh 0.5000g of lignocellulose, place it in 250mL of 20% NaOH aqueous solution with a mass fraction of 20%, fully stir it with a glass rod until it forms a suspension, and then use the SM-1200D ultrasonic cell pulverizer (Changzhou Guohua Electric Co., Ltd.) Ultrasonic treatment is performed on lignocellulose uniformly dispersed in alkaline ultrasonic medium, wherein the horn is Φ20mm, the ultrasonic temperature is 10°C, the ultrasonic generation time is 1.0s, the ultrasonic gap is 2.0s, the ultrasonic power is 1080W, and the ultrasonic time for 150 min, centrifuged, and the lower layer was taken for use.

Embodiment 2

[0097] The present embodiment provides a kind of preparation method of nanometer lignocellulose / montmorillonite composite material, it comprises the following steps:

[0098] 1. Weigh 0.5000 g of the nano-lignocellulose lower layer liquid obtained in Example 1, dissolve it in 75 mL of a 12.5% NaOH aqueous solution, and stir for 30 min at 60° C. to form a nano-lignocellulose suspension;

[0099] 2. Weigh 0.5000g of montmorillonite, dissolve it in 15mL of distilled water, stir at room temperature for 30min, and obtain a suspension of montmorillonite;

[0100] 3. Under the condition of constant stirring, slowly add the nano-lignocellulose suspension in the above step 1 to the montmorillonite suspension in the above step 2, stir and mix, heat up to 50°C, stir for 4 hours, and filter with suction , wash the product with distilled water until neutral, vacuum-dry at 85°C for 240 minutes, and grind the dried product through a 200-mesh sieve to obtain a nano-lignocellulose / montmorill...

Embodiment 3

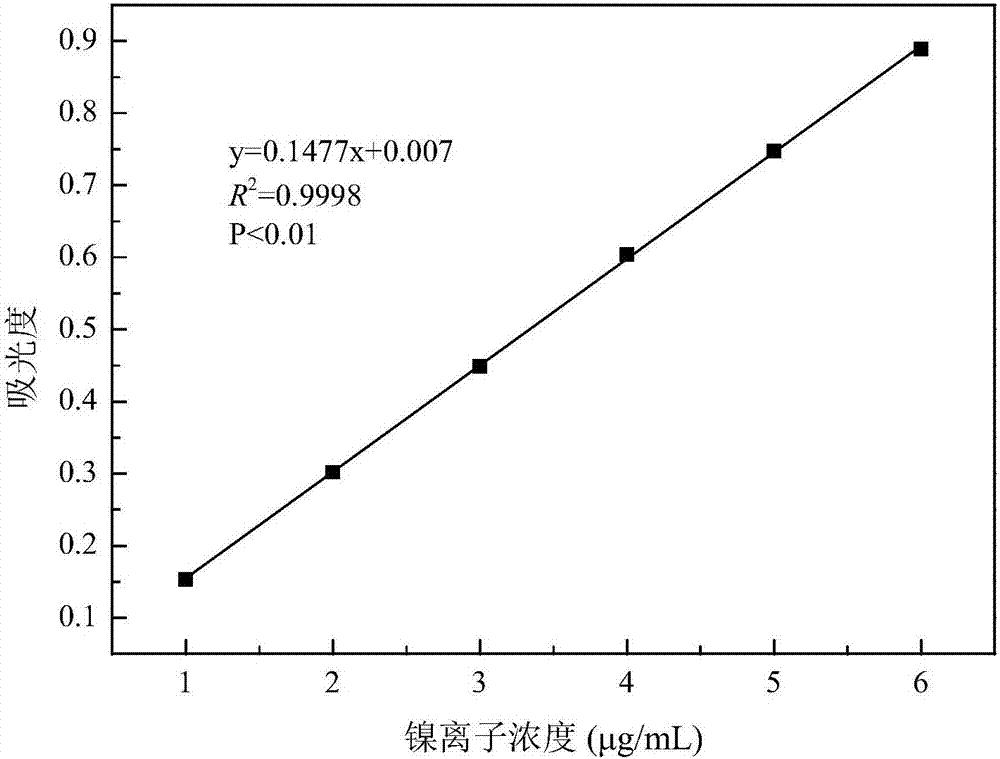

[0115] This embodiment provides the application of the nano-lignocellulose / montmorillonite composite material obtained in Example 2 in the adsorption of heavy metal ions, which specifically includes the following steps:

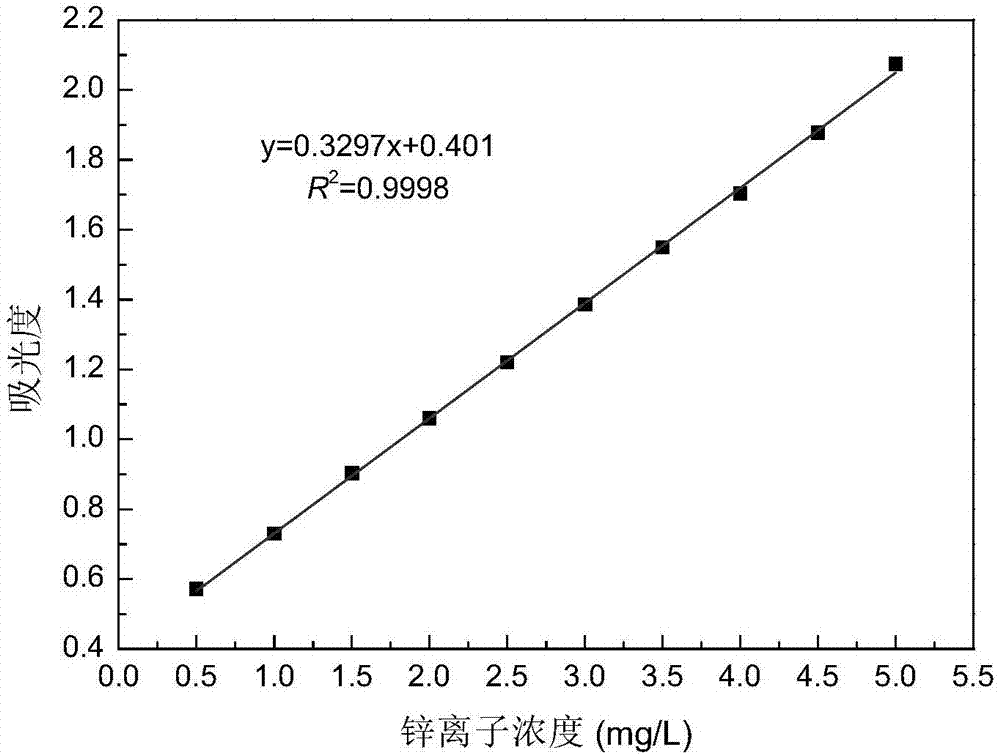

[0116] 1. Get the prepared nano-lignocellulose / montmorillonite composite material 0.0500g of above-mentioned embodiment 2, put into the aqueous solution containing Zn (II) and carry out adsorption capacity test, setting temperature is placed in constant temperature oscillator (6000r / min ), wherein the concentration of Zn(II) in the solution is 1000 mg / L, the pH value is 2.6, the adsorption temperature is 65° C., and the adsorption time is 120 min, the absorbance is measured, and the adsorption amount is calculated.

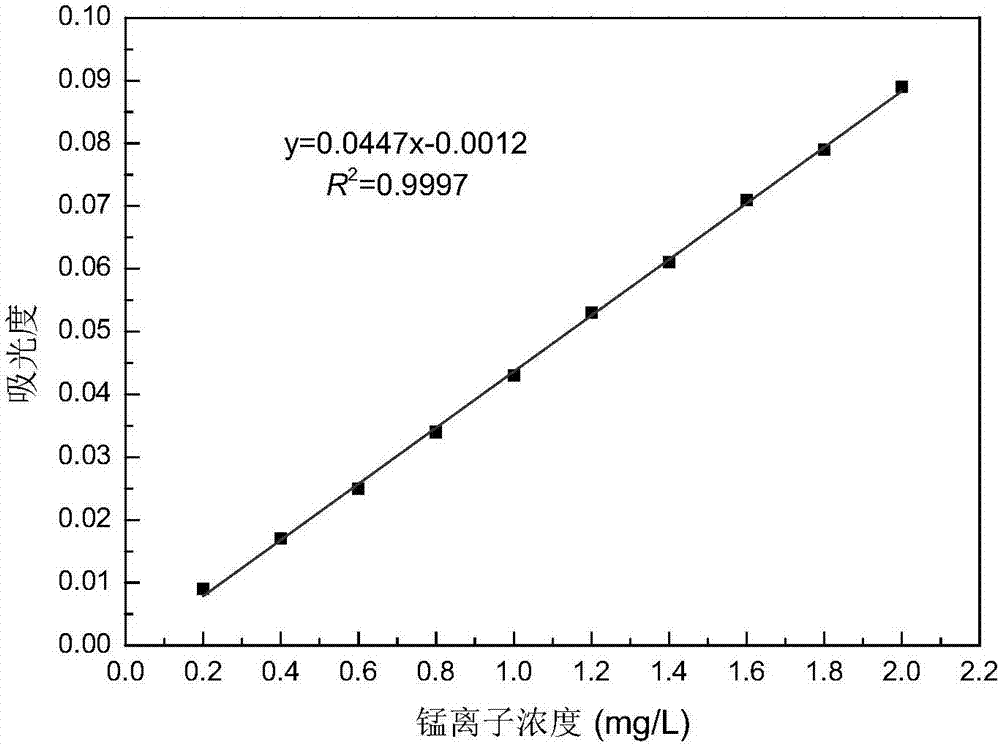

[0117] 2. In addition, get 0.0500g of nano-lignocellulose / montmorillonite composite material prepared in the above-mentioned embodiment 2, put it into an aqueous solution containing Mn(II) and carry out the adsorption capacity test, set the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com