High-energy storage density polypropylene-maleic anhydride grafted polypropylene-nano-zirconia composite material and preparation method thereof

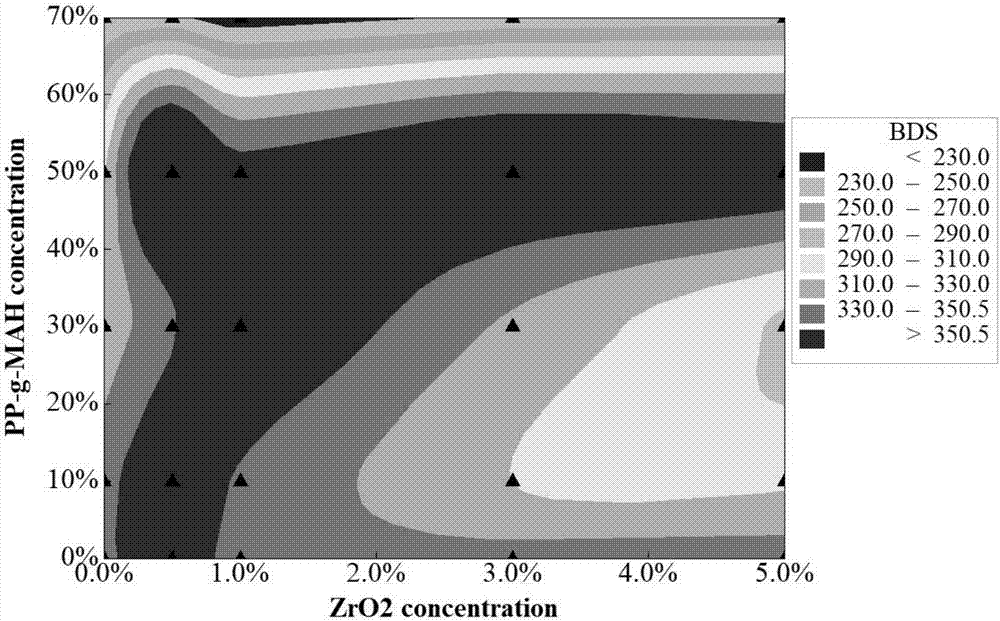

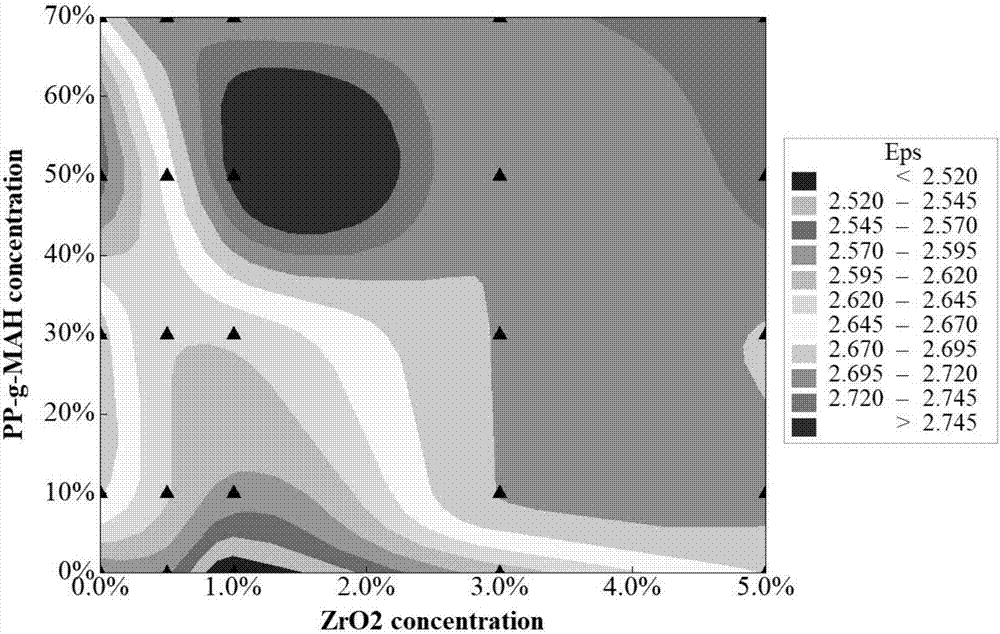

A technology of grafting polypropylene and nano-zirconia is applied in the field of power capacitors to achieve the effect of increasing the breakdown field strength and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of high energy storage density polypropylene-maleic anhydride grafted polypropylene-nano zirconia composite material

[0029] The first step (masterbatch preparation):

[0030] Add maleic anhydride-grafted polypropylene and nano-zirconia into the torque rheometer, and antioxidant 1010 with a mass fraction of 0.3%, and melt blend at 180° C. for 10 minutes to obtain a masterbatch.

[0031] The second step (composite material preparation):

[0032] Add polypropylene, maleic anhydride grafted polypropylene and masterbatch into the torque rheometer, and after the torque is stable, add 0.12g of antioxidant 1010 (accounting for 0.3% of the total mass). Under the conditions of 40r / min and 180°C, melt compounding was carried out for 20 minutes.

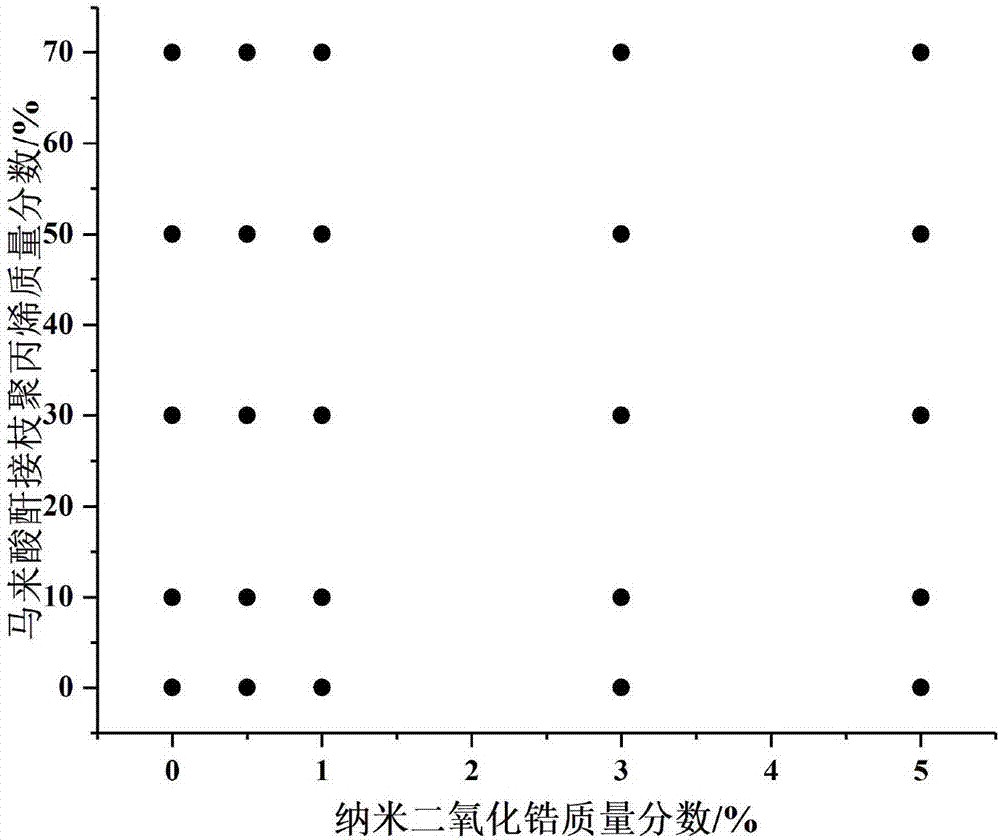

[0033] In the mixture, the total mass of polypropylene and maleic anhydride-grafted polypropylene is 40g, and the mass proportions of maleic anhydride-grafted polypropylene are 0, 10%, 30%, 50%, and 70%, respect...

Embodiment 2

[0034] Example 2: Preparation of a high energy storage density polypropylene-maleic anhydride grafted polypropylene-nano zirconia composite film

[0035] 1) Cut a circular hole with a diameter of 50 mm on a polyimide film with a thickness of about 120 μm as a mold.

[0036] 2) Put 0.26g of composite material into each round hole of the mold, use a flat vulcanizer, preheat for a period of time at 190°C, exhaust, and then hot press at 20MPa to obtain polypropylene-maleic anhydride Grafted polypropylene-nano zirconia composite film.

[0037] Among them, the preheating time at 190°C can be set to 280-320s, for example, it can be set to 300s, and the number of exhausts can be set to 10-15 times, each time 9-11s, for example, it is set to exhaust 10 times, every time The time is 10s; under 20MPa, the hot pressing time can be set to 280-320s, for example, it can be set to 300s, the diameter of the film sample is 50mm, and the thickness is about 130μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com