High-heat-conduction and insulating adhesive composition and preparation method thereof

A technology of adhesives and compositions, applied in the directions of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of poor compatibility, reduced adhesive performance and insulation performance of adhesives, low thermal conductivity, etc. The effect of improving dispersibility, improving thermal conductivity, and efficient heat conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

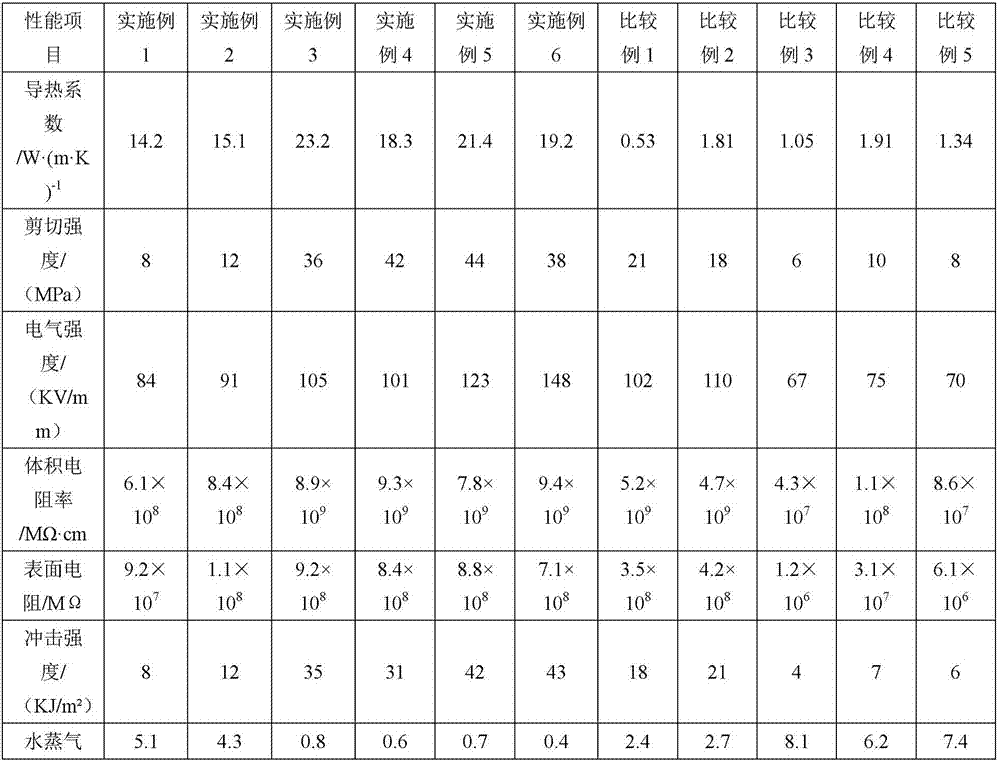

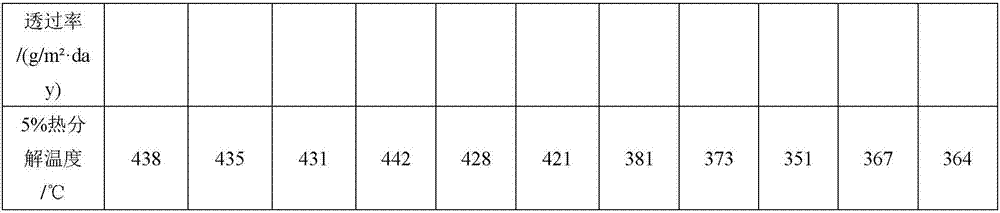

Examples

preparation example Construction

[0042] The preparation of the thermally conductive filler modified by the silane coupling agent is carried out in a solvent, for example, in absolute ethanol solution. The inventors of the present invention found that adjusting the reaction environment to be weakly alkaline is beneficial to the preparation of modified thermally conductive fillers with good performance. For example, the pH of the reaction solution can be adjusted to 8-9. The pH can be adjusted with an alkaline solution, for example, a 10% aqueous NaOH solution.

[0043] When preparing thermally conductive fillers modified by silane coupling agents, in some cases, the surface modification reaction can be accelerated by heating. For example at temperatures around 80° C., sufficient surface modification can be achieved after 30 minutes.

[0044] After the reaction, the reaction solution can be dried to obtain a dry silane coupling agent-modified thermally conductive filler.

[0045] The preparation of isocyanat...

Embodiment 1

[0058] Through the following steps, a high thermal conductivity insulating adhesive composition is prepared, which comprises 50 parts of epoxy adhesive, 330 parts of alumina MZS-330 parts, 20 parts of boron nitride JYBN-001020 parts, 8 parts of graphene oxide, and isophorone in parts by weight. 14 parts of diisocyanate, 1714 parts of coupling agent KH, 10100.6 parts of antioxidant.

[0059] (1) Surface modification of thermally conductive filler: in parts by weight, 4 parts of silane coupling agent KH171 are dissolved in absolute ethanol, and the pH value is adjusted to 8 with 10% aqueous sodium hydroxide solution, and then 30 parts of aluminum oxide and 20 parts of boron nitride were stirred and reacted at 80° C. for 30 minutes, and vacuum-dried to obtain a coupling agent-modified thermally conductive filler.

[0060] (2) Functional modification of graphene oxide: in parts by weight, 8 parts of graphene oxide were added to anhydrous DMF, ultrasonically dispersed for 25 min, 1...

Embodiment 2

[0064] Through the following steps, a high thermal conductivity insulating adhesive composition is prepared, which comprises 60 parts of polyurethane adhesive, 30 parts of aluminum nitride TFZ-N01P, 4 parts of graphene oxide, 13 parts of toluene diisocyanate, and silane coupling agent KH5705 in parts by weight. parts, antioxidant 6260.7 parts.

[0065] (1) Surface modification of thermally conductive filler: in parts by weight, dissolve 5 parts of silane coupling agent KH570 in absolute ethanol, adjust the pH value to 8 with 10% aqueous sodium hydroxide solution, and then add 30 parts of aluminum nitride , stirred and reacted at 80° C. for 30 minutes, and vacuum-dried to obtain a coupling agent-modified thermally conductive filler.

[0066] (2) Functional modification of graphene oxide: in parts by weight, 4 parts of graphene oxide were added to anhydrous DMF, ultrasonically dispersed for 25 min, 13 parts of diphenylmethane diisocyanate were added, and ultrasonically reacted f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com