Preparation method of half pea polypeptide of chickpea and application thereof

A technology of chickpea watercress and chickpea, which is applied to the preparation method of peptides, chemical instruments and methods, and medical preparations containing active ingredients, etc., which can solve the problems of waste of rare and unique plant resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

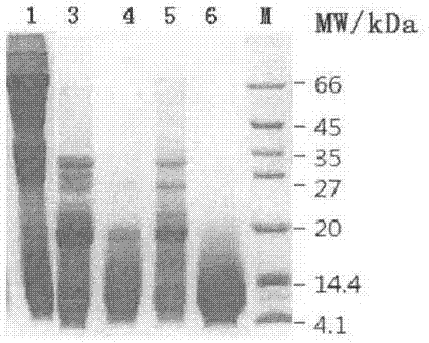

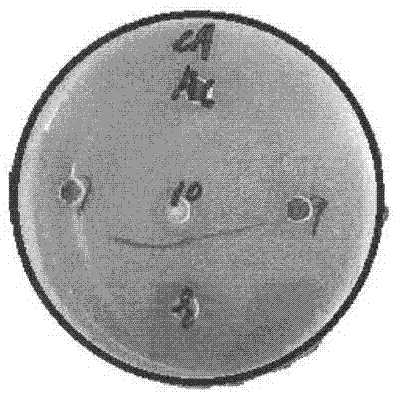

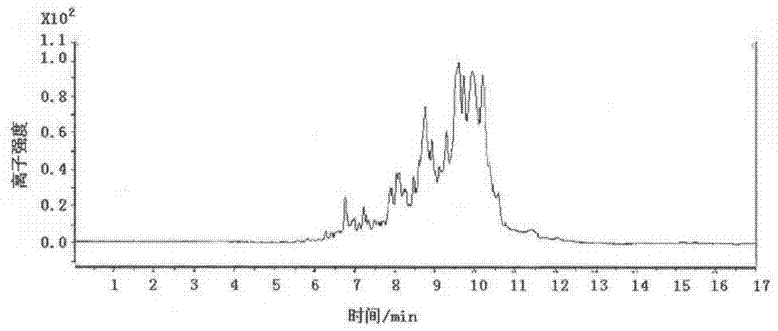

Image

Examples

Embodiment 1

[0034] a. Grind 613g of dry watercress after germinating and peeling chickpeas, pass through a 80-mesh sieve, add petroleum ether according to w / v soybean powder: petroleum ether = 1:5, shake at room temperature for 4 hours, and repeatedly extract 3-4 times Until it is colorless, the chickpea watercress powder is naturally settled and separated from petroleum ether, and the upper layer of petroleum ether is poured out for recovery. The precipitates are combined and dried naturally to obtain 516.7g of defatted chickpea watercress powder with an oil extraction rate of 96.3 / 613=15.7%, put it in a -20℃ refrigerator and store it for later use;

[0035] b. Add 350ml of phosphate buffer solution with a pH of 7.4 and 0.1M to 100g of degreased chickpea watercress powder in step a, the ratio of solid to liquid is 1:3.5, the temperature is 4°C, and the extraction is carried out for 48h;

[0036] c. The extract in step b was filtered, 10000r / min, temperature 4°C, centrifuged for 10min, t...

Embodiment 2

[0042] a. Grind 613g of dry watercress after germinating and peeling chickpeas, pass through a 80-mesh sieve, add petroleum ether according to w / v soybean powder: petroleum ether = 1:5, shake at room temperature for 4 hours, and repeatedly extract 3-4 times Until it is colorless, the chickpea watercress powder is naturally settled and separated from petroleum ether, and the upper layer of petroleum ether is poured out for recovery. The precipitates are combined and dried naturally to obtain 516.7g of defatted chickpea watercress powder with an oil extraction rate of 96.3 / 613=15.7%, put it in a -20℃ refrigerator and store it for later use;

[0043] b. Add 350ml of phosphate buffer solution with a pH of 7.4 and 0.1M to 100g of degreased chickpea watercress powder in step a, the ratio of solid to liquid is 1:3.5, the temperature is 4°C, and the extraction is carried out for 48h;

[0044] c. The extract in step b was filtered, 10000r / min, temperature 4°C, centrifuged for 10min, t...

Embodiment 3

[0050] a. Grind 613g of dry watercress after germinating and peeling chickpeas, pass through a 80-mesh sieve, add petroleum ether according to w / v soybean powder: petroleum ether = 1:5, shake at room temperature for 4 hours, and repeatedly extract 3-4 times Until it is colorless, the chickpea watercress powder is naturally settled and separated from petroleum ether, and the upper layer of petroleum ether is poured out for recovery. The precipitates are combined and dried naturally to obtain 516.7g of defatted chickpea watercress powder with an oil extraction rate of 96.3 / 613=15.7%, put it in a -20℃ refrigerator and store it for later use;

[0051] b. Add 350ml of phosphate buffer solution with a pH of 7.4 and 0.1M to 100g of degreased chickpea watercress powder in step a, the ratio of solid to liquid is 1:3.5, the temperature is 4°C, and the extraction is carried out for 48h;

[0052]c. The extract in step b was filtered, 10000r / min, temperature 4°C, centrifuged for 10min, te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com