Solid ion selective electrode as well as preparation and application thereof

An ion-selective electrode technology, applied in solid-state ion-selective electrodes and its preparation and application fields, can solve problems such as limiting the selection of inorganic transduction materials, and achieve fast detection speed, good potential stability, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific preparation steps of the solid contact potassium ion selective electrode are as follows:

[0027] 1) Preparation of sensitive membrane: Weigh 200 mg of potassium ion polymer membrane components (PVC particles, o-nitrophenyl octyl ether, potassium ionophore and tetrakis (3,5-bis(trifluoromethyl)phenyl) sodium borate) ), where the mass fractions are PVC particles: 32.8wt%, o-nitrophenyl octyl ether: 65.6wt%, potassium ionophore valinomycin: 1.0wt%, tetrakis(3,5-bis(trifluoromethyl) Sodium phenyl)borate: 0.6 wt%. After the weighing is completed, the above mixture is transferred to 1.6 mL of tetrahydrofuran solution, ultrasonicated and stirred for 2 hours to completely dissolve it.

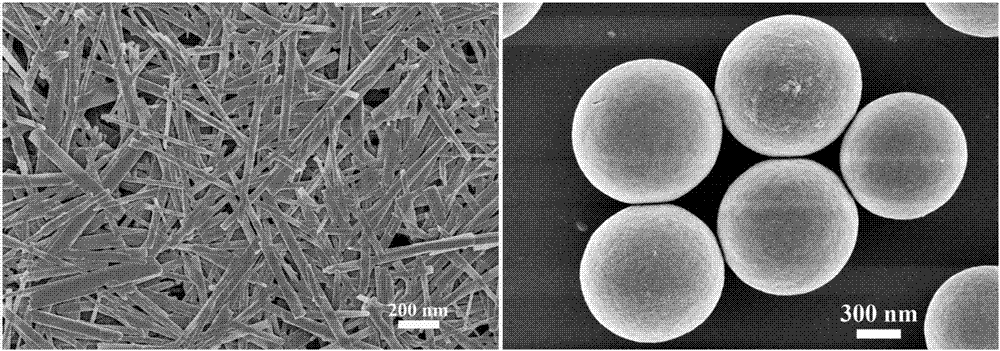

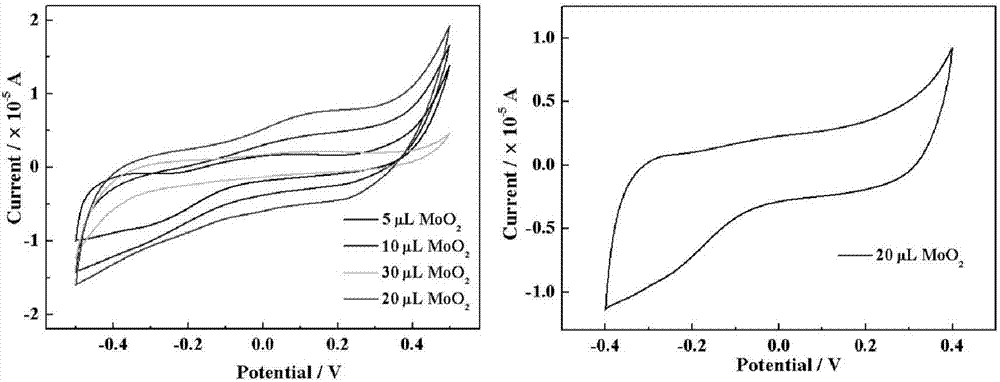

[0028] 2) MoO with specific micro morphology 2 Preparation of microspheres:

[0029] Ⅰ. MoO 3 Preparation of nanoribbons.

[0030] Weigh 1.68g of Na 2 MoO 4 ·2H 2 O, dissolved in 35mL water and stirred for 30min to prepare Na with a concentration of 0.2M 2 MoO 4 Aqueous solution, ready f...

Embodiment 2

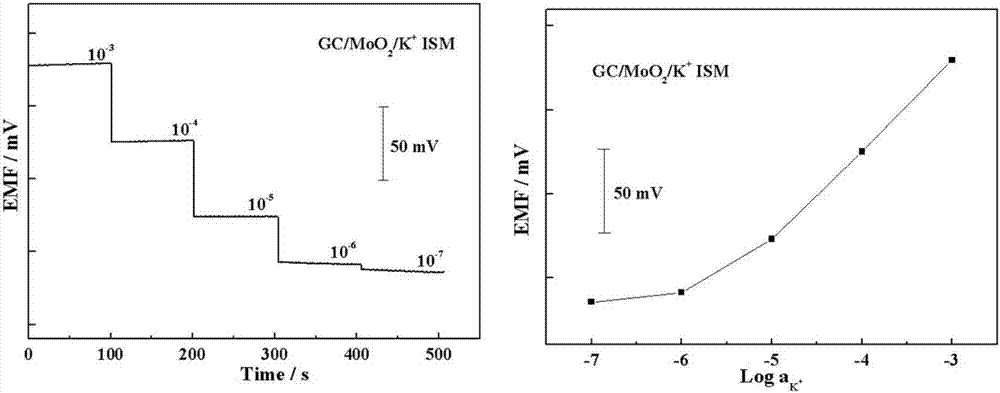

[0037] Based on MoO 2 After the preparation of the solid-state potassium ion selective electrode transduced by the microspheres is completed, the concentration is 10% before being used for the determination of potassium ions in the solution. -3 M potassium chloride solution is activated for 24h.

[0038] When the electrode is used for measurement, use MoO 2 The transducing solid potassium ion selective electrode is used as the working electrode, and the saturated calomel electrode connected with 0.1M lithium acetate bridge is used as the reference electrode, and the two constitute a test loop system. Put the above electrode system at a concentration of 10 -3 , 10 -4 , 10 -5 ,10 -6 , 10 -7 In the mol / L KCl solution, the data is collected by lightning, and the corresponding potential time curve and potential and concentration curve are drawn, see image 3 .

[0039] by image 3 It can be seen that the solid-state potassium ion selective electrode based on MoO2 microsphere transducti...

Embodiment 3

[0041] 1) MoO with specific morphology 3 Preparation of nanoribbons:

[0042] Weigh 8.58g of (NH 4 ) 2 MoO 4 ·7H 2 O, dissolved in 35mL water and stirred for 30min to prepare (NH 4 ) 2 MoO 4 Aqueous solution, ready for use; measuring cylinder to measure 27mL concentrated nitric acid HNO 3 Add to 100mL of distilled water under stirring conditions to prepare HNO with a concentration of about 4M 3 Aqueous solution. Measure a certain amount of HNO 3 The solution was added dropwise to the above (NH 4 ) 2 MoO 4 In the solution, and adjust the pH of the ammonium molybdate solution to about 1. Then, continue to stir and react for 30 minutes at room temperature. After that, transfer the above mixture into a 50mL polytetrafluoroethylene lined reactor and place it in a muffle furnace at 180°C for 24 hours. After completion, cool to room temperature and filter. Collect the product and rinse with ethanol and deionized water to get MoO 3 product.

[0043] 2) The rest of the implementation steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com