Purification method and system for VOCs exhaust gas in constructed wetlands

A technology for exhaust gas purification systems and constructed wetlands, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high manufacturing and operating costs of membrane separation methods, unsuitable for large-scale industrial applications, and catalyst deactivation. , to achieve the effect of improving the quality of the atmospheric environment, eliminating adverse effects, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment specifically illustrates the technical solution of the system of the present invention.

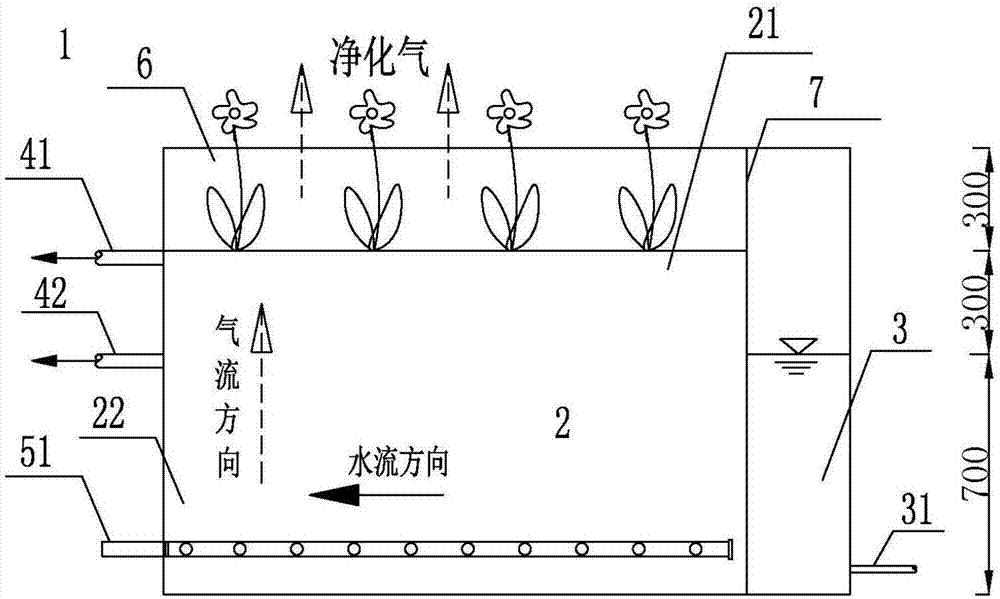

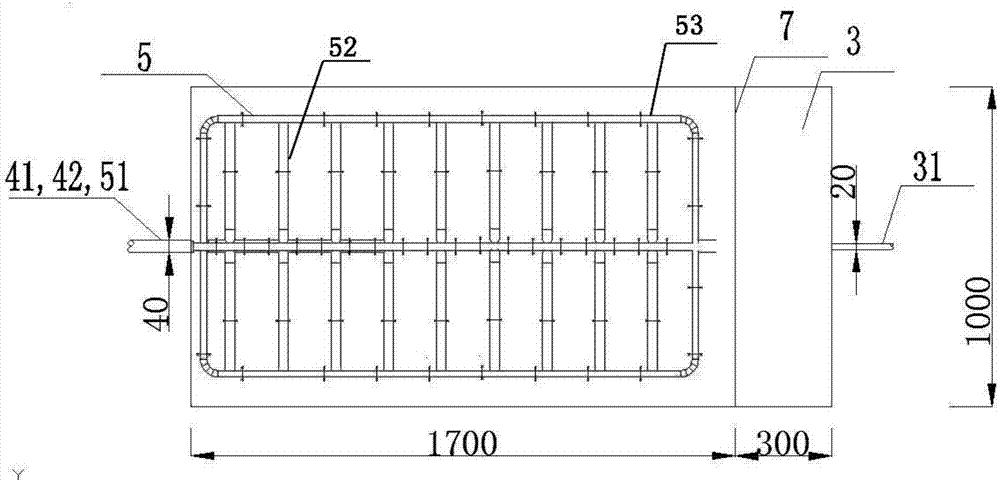

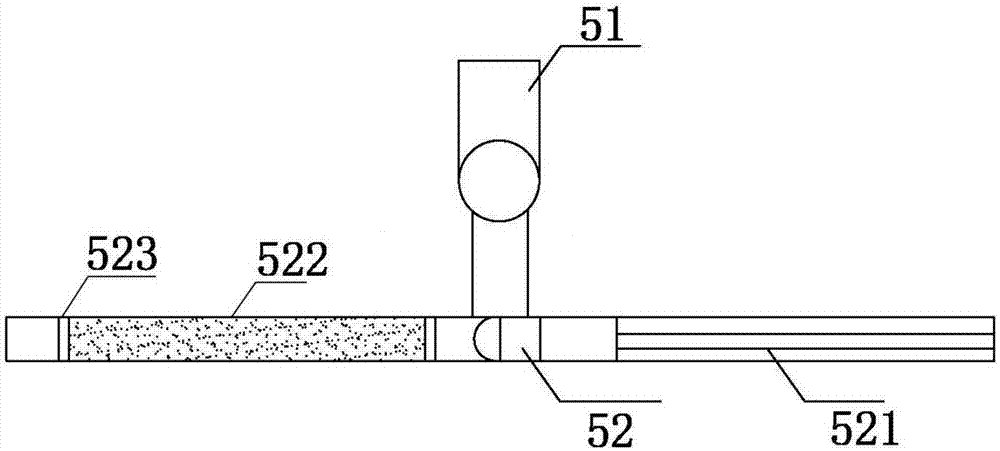

[0037] Such as Figure 1-Figure 3 The shown constructed wetland VOCs exhaust gas purification system includes a constructed wetland pool body 1, a filler, a water inlet device, a water outlet device, an air distribution device 5 and aquatic plants 6; the constructed wetland pool body 1 is formed by excavating earth below the ground , And tamped clay on the inner wall as an impermeable layer; the constructed wetland pool body 1 is divided into filling area 2 and water distribution area 3 in the horizontal direction. Filling area 2 and water distribution area 3 are separated by perforated plates 7, and water distribution area 3 is provided with Water inlet device 31; there is a filler in the filler area 2, and the filler area 2 in the vertical direction from bottom to top is a water-saturated filler layer 22 and a water-unsaturated filler layer 21; above the filler layers...

Embodiment 2

[0043] This example illustrates the method of using the system described in Example 1.

[0044] In this embodiment, the system structure size is as specific as figure 1 As shown, the pool body: the pool body of the constructed wetland is rectangular on the plane (round, square or irregular shape can also be used), the thickness of the impermeable layer is 0.05m, and the degree of compaction is 97%; the height of the filling in the pool is 1.0m, the height of the saturated water layer at the bottom is 0.7m, the height of the top unsaturated layer is 0.3cm, the super height is 0.3m, and the total height is 1.3m.

[0045] The service area of the air distribution device in this embodiment is 0.3-1.5m 2 / m, ventilation volume 1-10m 3 / m﹒ h, the pore density is 15000-20000 / m, the stroke bubble diameter is 0.5-5mm.

[0046] The system operating parameters are as follows:

[0047] The particle size of the medium volcanic slag is 2-3cm;

[0048] Air inlet flow rate 100-200m 3 / h;

[0049] Air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com