Method of using polyethylene imine to extract and separate phenolic substances from coal tar

A technology of polyethyleneimine and phenolic substances, which is applied in the field of coal chemical industry, can solve the problems of complex operation process, strong corrosion of equipment, and limited industrial application prospects, etc., and achieve the effect of simple process, stable physical properties and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

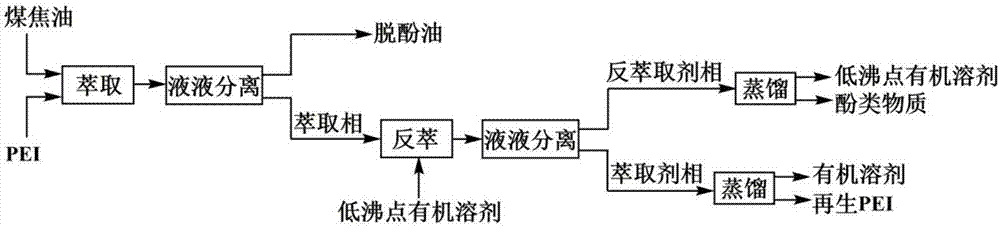

Method used

Image

Examples

Embodiment 1

[0018] Mix PEI with an average molecular weight of 10,000 and coal tar (a simulated oil mixed with phenol and toluene, wherein the content of phenol is 15wt%) according to a mass ratio of 0.2, so that the two are fully contacted, and extracted at 30 ° C for 60 minutes, so that the phenol As many substances as possible enter the extractant from the oil to obtain the extract phase and dephenolized oil. The stripping agent diethyl ether and the extracting phase were uniformly mixed at a mass ratio of 0.4, and stripping was carried out for 60 min at normal temperature to obtain the stripping agent phase and the extracting agent phase. The back-extractant phase and the extractant phase were distilled at 50°C and 0.01MPa for about 1 hour to obtain phenolic substances, regenerated PEI and ether. After calculation, the recovery rate of phenolic substances was 29.6%.

Embodiment 2

[0020] PEI with an average molecular weight of 600 and coal tar (a simulated oil mixed with phenol, toluene and n-octane, wherein the content of toluene is 50wt% and the content of phenol is 15wt%) is mixed according to the mass ratio of 0.5, so that the two are fully contacted , extracted at 30°C for 60 min, so that as much phenolic substances as possible entered the extractant from the oil to obtain the extract phase and dephenolized oil. The stripping agent diethyl ether and the extracting phase were uniformly mixed at a mass ratio of 0.4, and stripping was carried out for 60 min at normal temperature to obtain the stripping agent phase and the extracting agent phase. The back-extractant phase and the extractant phase were distilled at 60°C and 0.01MPa for about 0.5h to obtain phenolic substances, regenerated PEI and ether. After calculation, the recovery rate of phenolic substances was 36.5%.

Embodiment 3

[0022] PEI with an average molecular weight of 600 is mixed with coal tar (the simulated oil formed by mixing phenol, toluene and n-octane, wherein the content of toluene is 50wt% and the content of phenol is 15wt%) according to the mass ratio of 1:1. Fully contact and extract at 30°C for 120 minutes, so that as much phenolic substances as possible enter the extractant from the oil to obtain the extract phase and dephenolized oil. The stripping agent diethyl ether and the extracting phase were uniformly mixed according to a mass ratio of 0.4:1, and stripping was carried out at room temperature for 30 minutes to obtain the stripping agent phase and the extracting agent phase. The back-extractant phase and the extractant phase were distilled at 60°C and 0.01MPa for about 0.5h to obtain phenolic substances, regenerated PEI and ether. After calculation, the recovery rate of phenolic substances was 36.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com