Method for performing mixed fermentation on lactobacillus acidophilus and clostridium butyricum as well as fermentation equipment thereof

A technology of Lactobacillus acidophilus and Clostridium butyricum, applied in the biological field, can solve the problems that Clostridium butyricum is easy to contaminate miscellaneous bacteria, reduce the utilization value of raw materials, and the production level is not high, so as to release the growth and reproduction ability of live bacteria, inhibit The growth of miscellaneous bacteria and the effect of strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

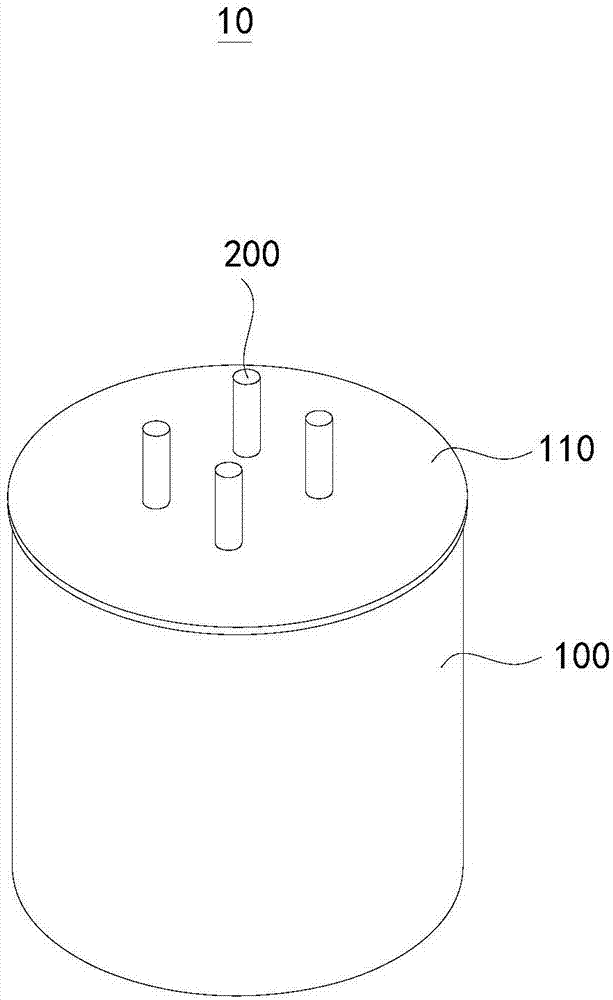

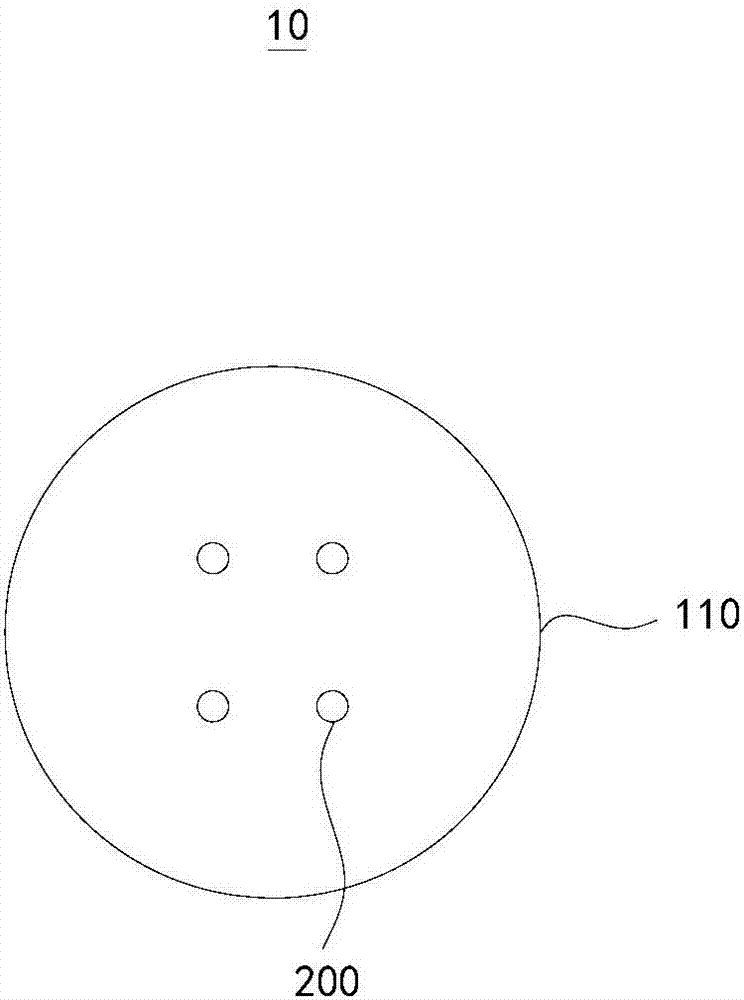

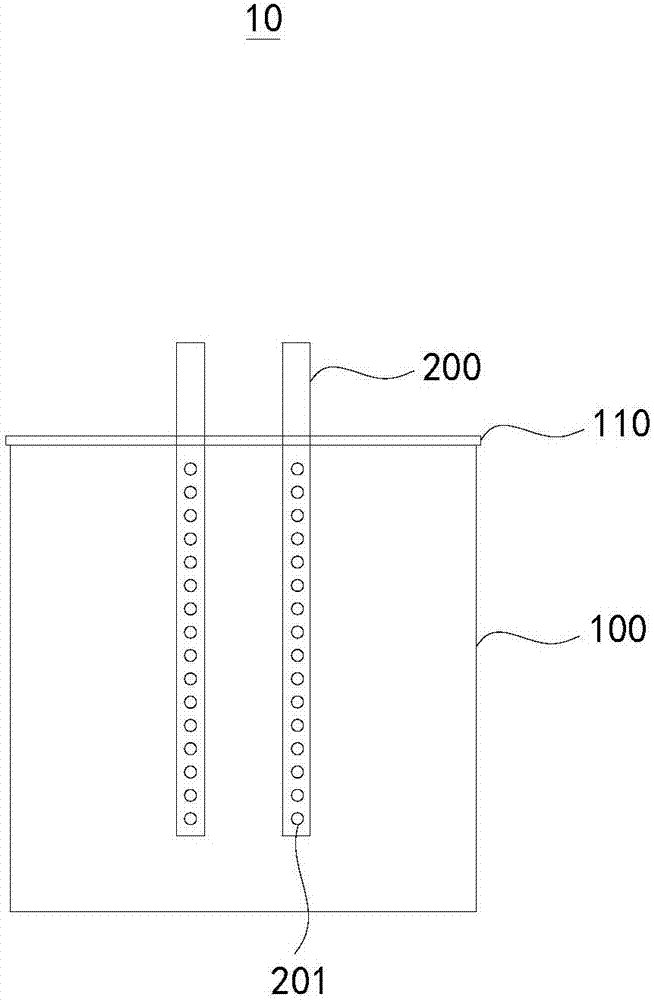

[0038] Please refer to the attached Figure 1~2 , the present invention provides a fermentation device 10, which includes a container body 100, and the container body 100 is provided with a one-way gas outlet channel.

[0039] Further, in this embodiment, the container body 100 is a cylindrical structure, which can be made of stainless steel, glass or porcelain. The diameter of the container body 100 can be 300-1000 mm, the height is 300-1000 mm, and the bottom and circumference are sealed.

[0040] The main body of the container 100 is used to accommodate the fermentation raw materials for the fermentation process. The one-way air outlet channel is provided on the main body of the container 100 to ventilate and discharge the hydrogen generated during the fermentation of Clostridium butyricum during the fermentation process, and at the same time relieve the effect of hydrogen on butyric acid. Metabolic inhibition produced by Clostridia. Clostridium butyricum is a strict anaer...

no. 2 example

[0046] This embodiment provides a mixed fermentation method of Lactobacillus acidophilus and Clostridium butyricum.

[0047] Mix 3 parts of yeast extract, 2 parts of brown sugar, 1 part of soybean meal powder, and 94 parts of water, adjust the initial pH to 7.5, sterilize at 121°C for 30 minutes, and cool to 37°C to obtain Lactobacillus acidophilus liquid medium. Take a Lactobacillus acidophilus strain preserved in a glycerol tube, and connect the strain to the Lactobacillus acidophilus culture medium at an inoculation amount of 0.1%, and then amplify and expand the culture step by step, which is the Lactobacillus acidophilus bacterial liquid. The number of live bacteria of Lactobacillus acidophilus is 220 million CFU / g.

[0048] Mix 2 parts of glucose, 1.5 parts of peptone, 1.5 parts of yeast extract powder, 0.1 part of ammonium sulfate, 0.1 part of sodium carbonate, 0.3 part of corn steep liquor, 0.05 part of manganese sulfate, 0.05 part of magnesium sulfate, and 95 parts of...

no. 3 example

[0054] The principle of the mixed fermentation method of Lactobacillus acidophilus and Clostridium butyricum provided in this embodiment is the same as that provided in the second embodiment, the difference is that the parameters are different, and the difference is as follows:

[0055] Mix 2 parts of yeast extract, 1 part of brown sugar, 0.5 part of soybean meal powder, and 92 parts of water, adjust the initial pH to 7, sterilize at 120°C for 35 minutes, and cool to 36°C to obtain Lactobacillus acidophilus liquid medium. Take the Lactobacillus acidophilus bacterial strain preserved in a glycerol tube, transfer the bacterial strain to the Lactobacillus acidophilus culture medium according to the inoculum amount of 0.08%, and enlarge and expand it step by step to obtain the Lactobacillus acidophilus bacterial liquid.

[0056] Mix 1 part of glucose, 1 part of peptone, 1 part of yeast extract powder, 0.05 part of ammonium sulfate, 0.05 part of sodium carbonate, 0.2 part of corn st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com