A kind of preparation method of phosphinate, phosphinate and non-aqueous electrolyte

A technology of phosphinate and intermediates, which is applied in the field of preparation of phosphinate, and can solve the problem of few synthetic methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The first step of reaction: add 170.0g of phosphorous trichloride and 1.5L solvent tetrahydrofuran to the reaction vessel, and stir evenly at room temperature, then add the tetrahydrofuran solution containing 191.0g of n-butylmagnesium bromide and continue stirring for 18h to obtain a reaction solution . The reaction solution was poured into 500 mL of 10 wt % sulfuric acid solution, extracted with ether and separated to obtain an organic layer, dried with anhydrous magnesium sulfate, and the solvent was distilled off under reduced pressure to obtain a solid mixture. The solid mixture was recrystallized from toluene and ethanol to give a white solid, which was dried in vacuo to give 74.0 g of product

[0069] The second step reaction: transfer 70.0g of the above product to a single-necked round-bottomed flask, add 85.9g of antimony trifluoride and start stirring, and connect the single-necked round-bottomed flask to a vacuum distillation device, and heat it to 165°C un...

Embodiment 2

[0075] The first step and the second step reaction are the same as in Example 1, and the difference is that the third step reaction is that the 36g colorless liquid product Transfer to a two-necked round-bottomed flask, keep the reaction vessel connected to the air, so as to utilize the moisture in the air, slowly stir at 27°C for 0.5 hours, then slowly stir and add 15.8g of n-butanol within 0.5 hours, at room temperature at 27°C React 1h to the end of the reaction. Obtain 33.3g (yield is 80%) product by distillation under reduced pressure

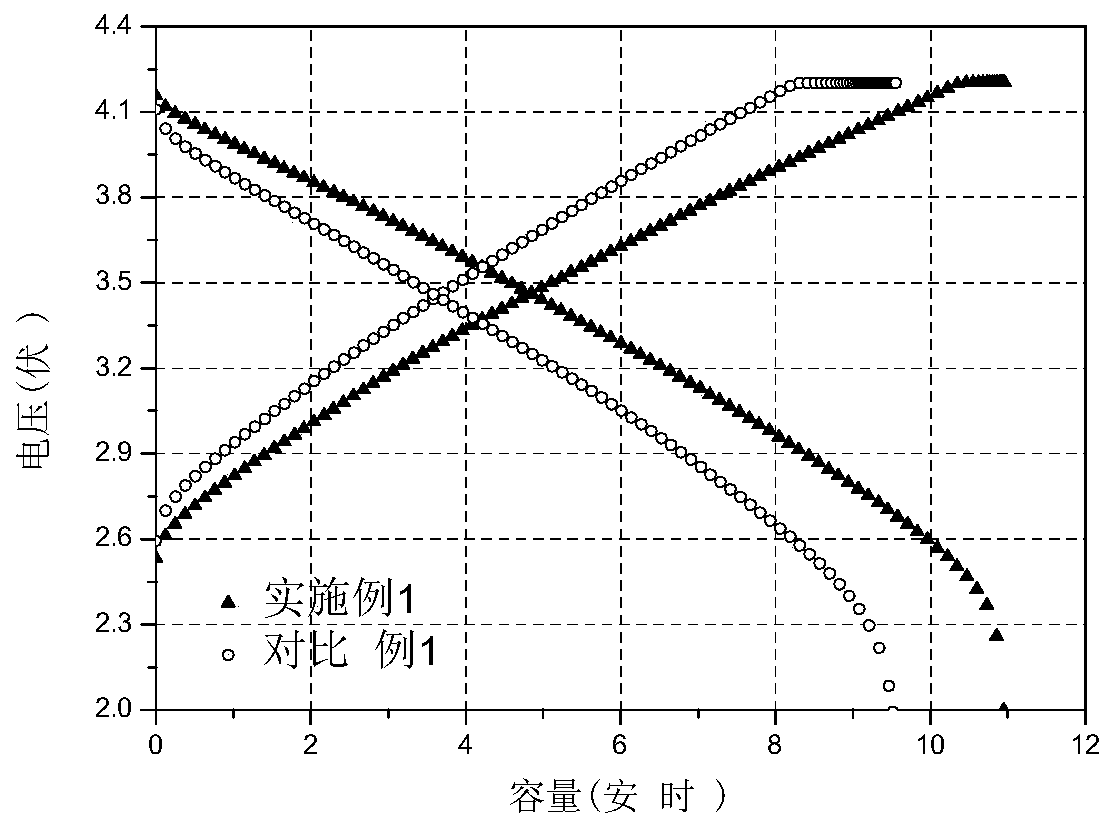

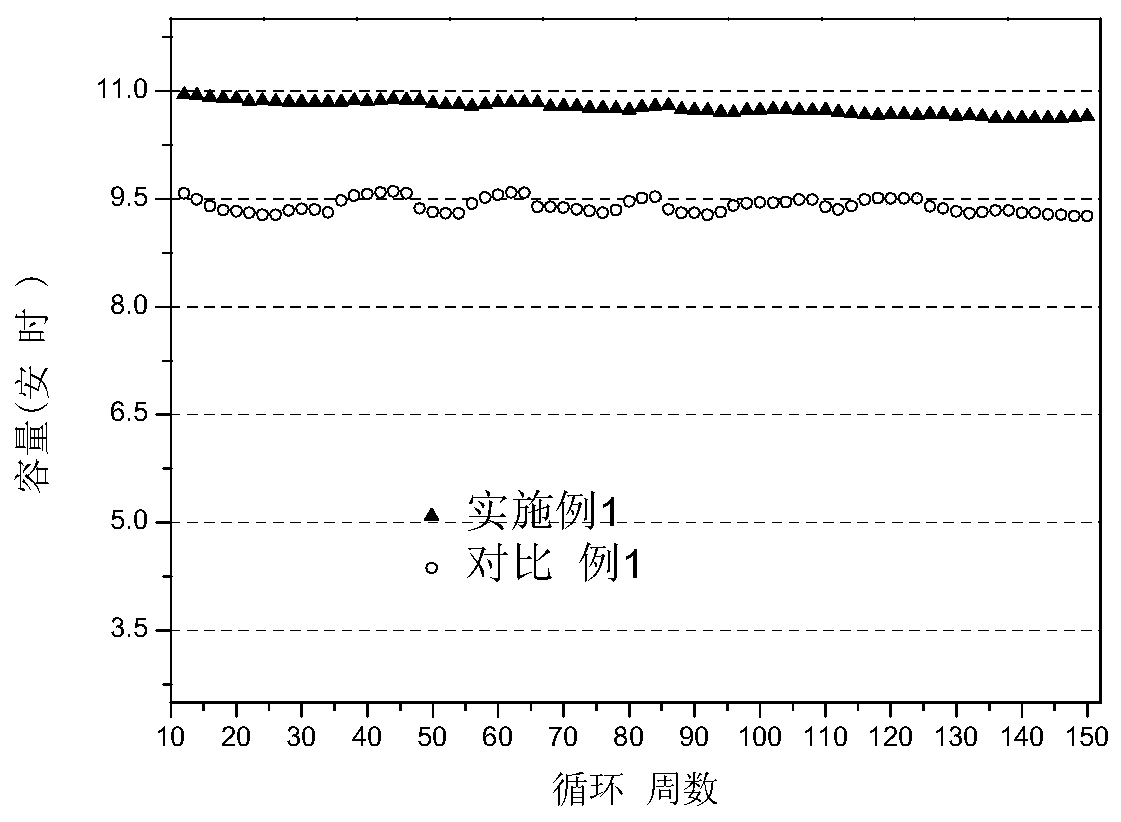

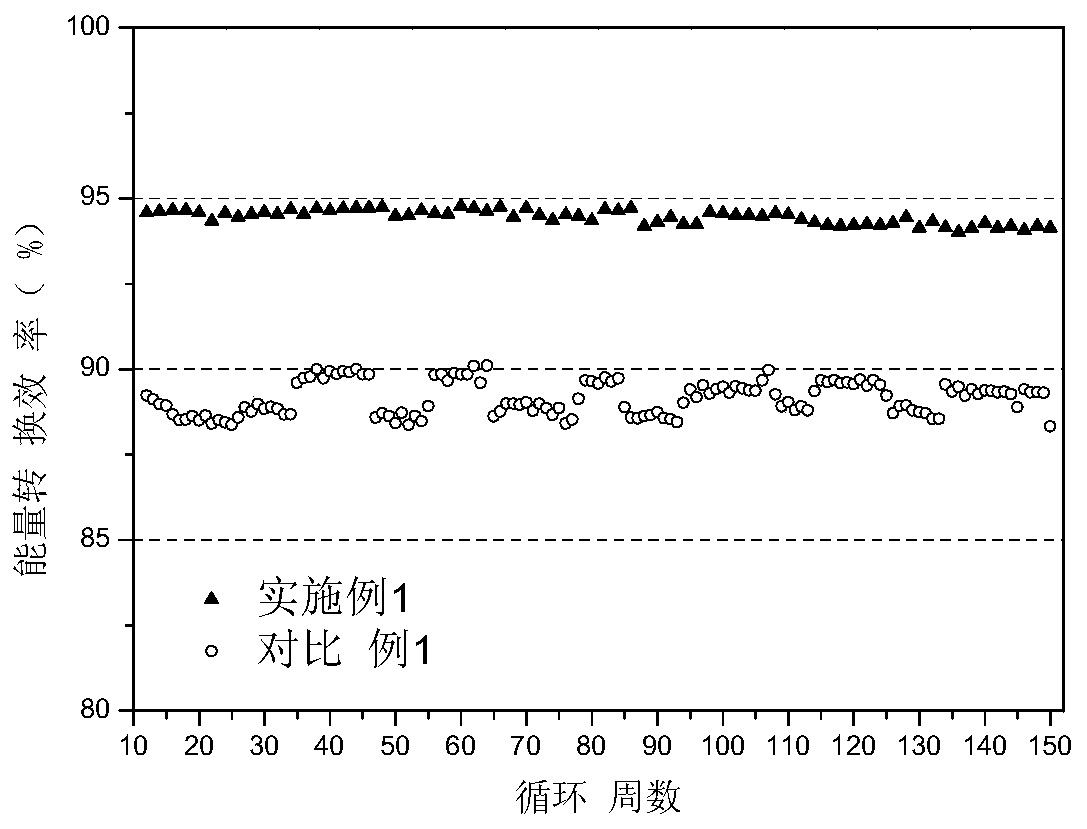

[0076] Non-aqueous electrolyte preparation: prepare non-aqueous mixed solvents of ethylene carbonate (EC), ethyl methyl carbonate (EMC) and dimethyl carbonate (DMC), the volume ratio of EC:EMC:DMC is 30:50:20, and then add to it (the content is 5.0 wt% of the mass of the non-aqueous electrolytic solution) and the film-forming additive vinylene carbonate (VC, the content of which is 2.0 wt% of the mass of the non-aqueous electrolytic ...

Embodiment 3

[0080] The first step reaction: add 170.0 g of phosphorous trichloride and 1.5 L of solvent tetrahydrofuran into the reaction vessel, and stir evenly at room temperature (25° C.). Then add 399.1 g of ethylmagnesium bromide in tetrahydrofuran (399.1 g refers to the mass of ethylmagnesium bromide) and continue to stir at 25°C until the reaction lasts for 48 hours to obtain a reaction solution. The reaction solution was poured into 500 mL of 10 wt% sulfuric acid solution, extracted with ether and separated to obtain an organic layer, which was dried with anhydrous magnesium sulfate, and the solvent was distilled off under reduced pressure to obtain a solid mixture. The solid mixture was recrystallized from toluene and ethanol to give a white solid, which was dried in vacuo to give 69.0 g of product

[0081] The second reaction step: transfer 69.0 g of the above product to a single-necked round bottom flask, add 108.0 g of antimony trifluoride and start stirring. And the single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com