Photoelectric flexible interconnection substrate and manufacturing technology thereof

A substrate and optoelectronic technology, applied in printed circuit manufacturing, multi-layer circuit manufacturing, circuit lamination, etc., to achieve the effects of reducing interconnection distance, improving high-density assembly, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

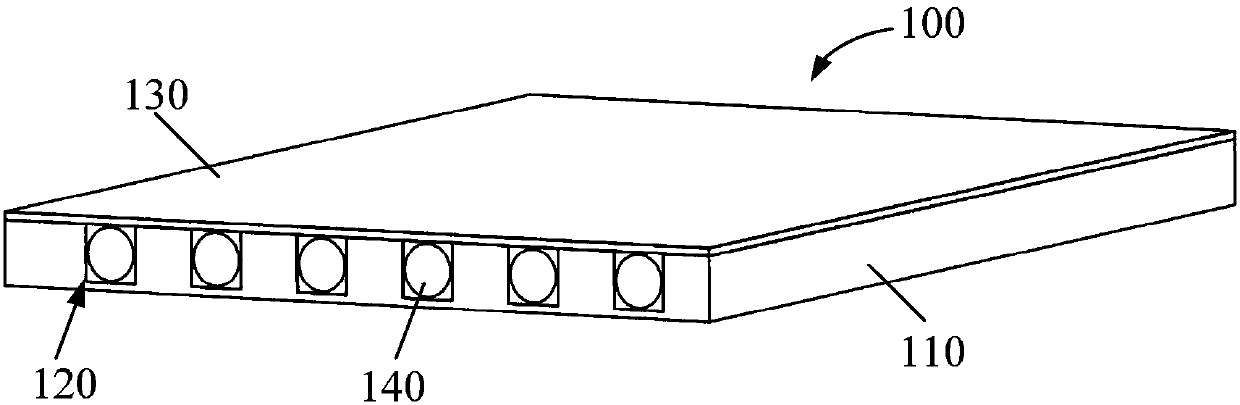

[0015] figure 1 The flexible optical circuit board 100 , which is the optoelectronic flexible interconnection substrate of the present invention, includes a flexible interconnection substrate 110 , a semi-cured gel layer 130 , and a high-temperature-resistant bare optical fiber 140 . Several high-precision positioning grooves 120 are made on the flexible interconnection substrate 110 by laser etching technology, and the high-temperature-resistant bare optical fiber 140 is embedded in the positioning grooves 120, and then a semi-cured colloid layer 130 is formed on the flexible interconnection substrate 110. The colloid layer 130 includes materials such as acrylic or epoxy resin, and the thickness can be 12.5 microns, 25 microns, 50 microns, etc.

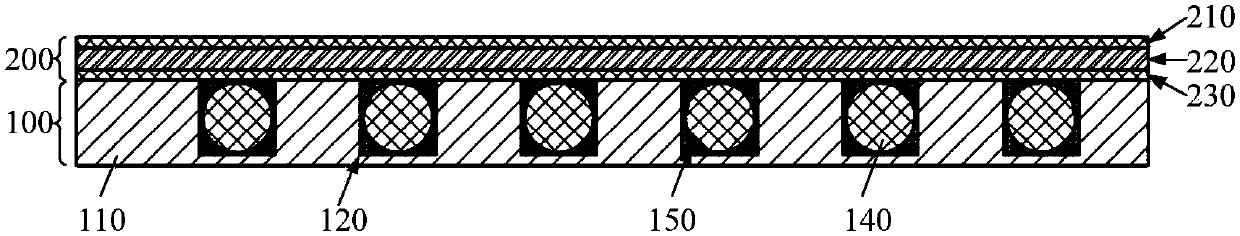

[0016] figure 2 It is a schematic diagram of the optoelectronic flexible interconnection substrate of the present invention, and the optoelectronic flexible substrate of the present invention is composed of a flexible optical circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com