Method for removing sulfur dioxide in smoke by using manganese carbonate ore and preparing manganese sulfate solution

A technology of manganese sulfate solution and manganese carbonate ore, applied in the direction of manganese sulfate, chemical instruments and methods, separation methods, etc., can solve the problems affecting the long-term process, continuous stability, lower than the national environmental protection emission standards, and affecting the application of desulfurization process, etc., to achieve The effects of fast filtration and impurity removal, easy reaction process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the raw material manganese carbonate ore from somewhere in Guizhou is used. The ore contains Mn8.8%, Ca8%, Mg0.5%, Fe1.9%.

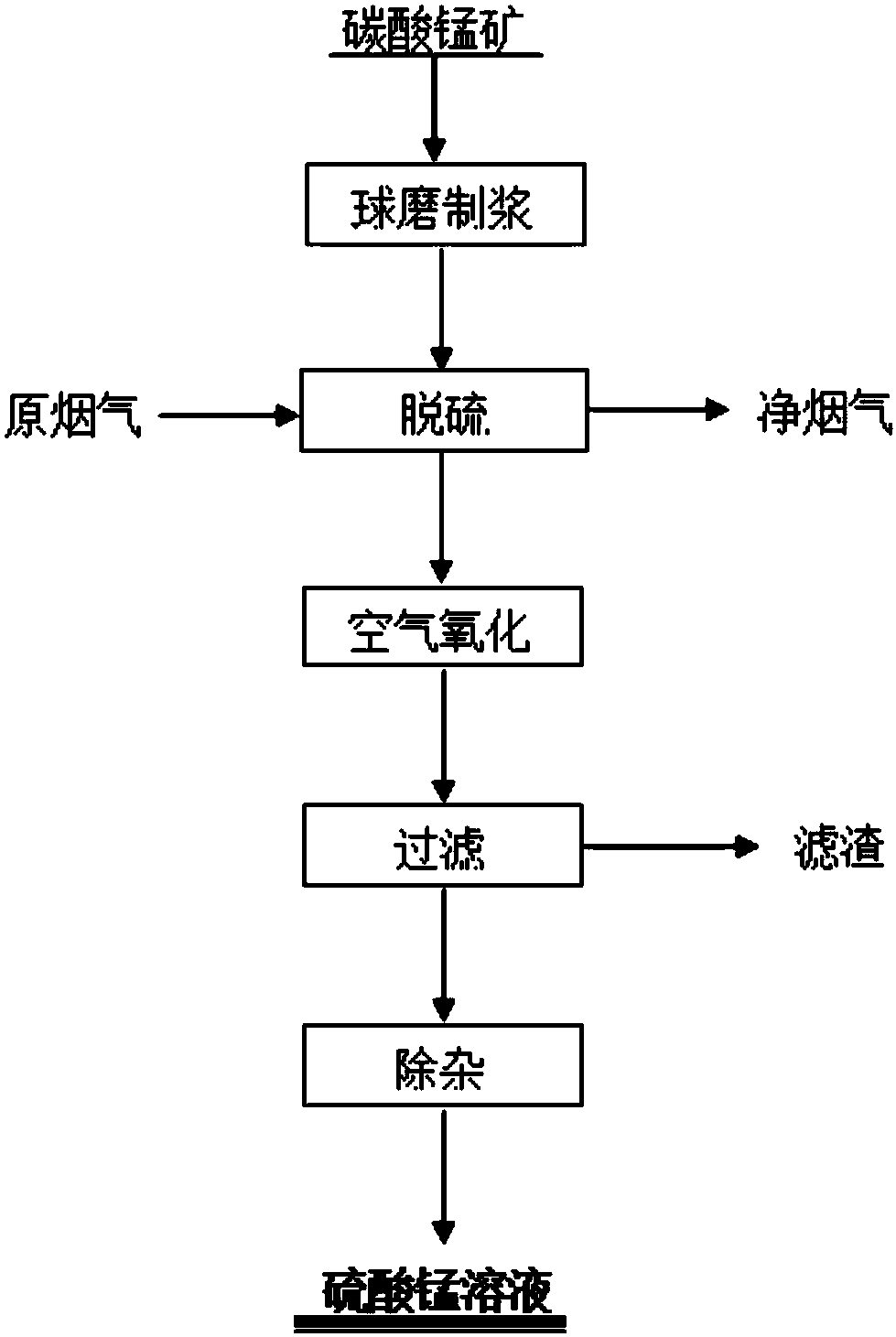

[0036] A kind of method of using above-mentioned manganese carbonate of the present invention to remove sulfur dioxide in flue gas and produce manganese sulfate solution, process flow chart is as figure 1 shown, including the following steps:

[0037] (1) Grinding and pulping: Use a crusher to crush the manganese carbonate ore until the maximum particle size does not exceed 6mm, transport the manganese carbonate ore into the ball mill and add water at a solid-to-liquid ratio of 1:1.5 for wet ball milling, wet method After ball milling, use a hydrocyclone to classify, overflow to the slurry transfer barrel, and obtain manganese carbonate slurry. According to the particle size test of the BT-9300HT laser particle size distribution analyzer, the particle size of the ore in the reaction slurry is less than 45 μm, accounting for 92...

Embodiment 2

[0042] In this embodiment, manganese carbonate ore powder from a certain place in Guizhou is used. The ore contains 10.8% Mn, 5.4% Ca, 0.5% Mg, and 1.8% Fe.

[0043] A method of removing sulfur dioxide in flue gas and producing manganese sulfate solution with above-mentioned manganese carbonate ore powder of the present invention, comprises the following steps:

[0044] (1) Grinding and pulping: the maximum particle size of the manganese carbonate ore powder in this embodiment is no more than 0.3mm, and the manganese carbonate ore powder is transported into the ball mill and added with water at a solid-to-liquid ratio of 1:1.2 for wet ball milling. Use the hydrocyclone to classify, overflow to the slurry transfer barrel, and obtain the manganese carbonate slurry. According to the particle size test of the BT-9300HT laser particle size distribution analyzer, the particle size of the ore in the reaction slurry is less than 45 μm, accounting for 95%.

[0045] (2) Absorption desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com