Two-dimensional boron nitride nano-composite hybrid proton exchange membrane and preparation method thereof

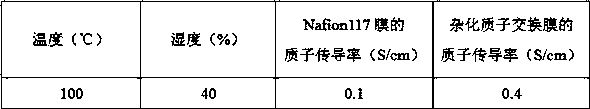

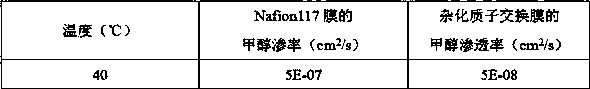

A nanocomposite and proton exchange membrane technology, which is applied in the field of two-dimensional boron nitride nanocomposite-based hybrid proton exchange membrane and its preparation, can solve the problem of methanol permeability reduction, achieve low methanol permeability, and promote proton exchange. The effect of transmission and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Disperse 2 g of boron nitride powder and 10 mL of 5 wt% Nafion solution in 200 mL of ethanol, and sonicate for 8 h; the suspension obtained after sonication was centrifuged at 3000 rpm for 20 min, and the supernatant was collected, washed with ethanol and Obtain Nafion-modified two-dimensional boron nitride nanocomposite aqueous phase dispersion after water centrifugal washing;

[0016] (2) Prepare 40 mL of 1 mg / mL two-dimensional boron nitride nanocomposite aqueous dispersion, add 1 mL of 20 mg / mL polyvinyl alcohol aqueous solution and 0.4 mL of commercially available 5 wt% Nafion solution. The resulting dispersion was suction-filtered under a pressure of 1 MPa to form a membrane. Then the membrane was removed from the basement membrane, treated with 1 M sulfuric acid at 30 °C for 2 h, and then washed with water to remove excess acid. Finally, ionomer-modified two-dimensional boron nitride nanocomposite-based hybrid proton exchange membrane was obtained.

[0017]...

Embodiment 2

[0024] (1) Disperse 4 g of boron nitride powder and 10 mL of 10 wt% Nafion solution in 400 mL of ethanol, and sonicate for 10 h; the suspension obtained after sonication was centrifuged at 2000 rpm for 15 min, and the supernatant was collected, washed with ethanol and Obtain Nafion-modified two-dimensional boron nitride nanocomposite aqueous phase dispersion after water centrifugal washing;

[0025] (2) Prepare 80 mL of 0.5 mg / mL two-dimensional boron nitride nanocomposite aqueous dispersion, add 2 mL of 10 mg / mL polyvinyl alcohol aqueous solution and 0.2 mL of commercially available 5 wt% Nafion solution. The resulting dispersion was suction-filtered under a pressure of 0.5 MPa to form a membrane. Then the membrane was removed from the basement membrane, treated with 0.5 M sulfuric acid at 40 °C for 1 h, and then washed with water to remove excess acid. Finally, ionomer-modified two-dimensional boron nitride nanocomposite-based hybrid proton exchange membrane was obtained. ...

Embodiment 3

[0027] (1) Disperse 2 g of boron nitride powder and 10 mL of 5 wt% Nafion solution in 400 mL of ethanol, and sonicate for 12 h; the suspension obtained after sonication was centrifuged at 5000 rpm for 15 min, and the supernatant was collected, washed with ethanol and Obtain Nafion-modified two-dimensional boron nitride nanocomposite aqueous phase dispersion after water centrifugal washing;

[0028] (2) Prepare 50 mL of 1.5 mg / mL two-dimensional boron nitride nanocomposite aqueous dispersion, add 5 mL of 20 mg / mL polyvinyl alcohol aqueous solution and 2 mL of commercially available 5 wt% Nafion solution. The resulting dispersion was suction-filtered under a pressure of 0.8 MPa to form a membrane. Subsequently, the membrane was removed from the basement membrane, treated with 0.5 M hydrochloric acid at 30 °C for 1.5 h, and then washed with water to remove excess acid. Finally, ionomer-modified two-dimensional boron nitride nanocomposite-based hybrid proton exchange membrane was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com