Application of carbon-supported ruthenium nanomaterials in the catalytic reaction of aromatic amines and aromatic methanol

A technology of nanomaterials and aromatic amines, applied in the field of catalytic chemistry, can solve problems such as environmental pollution, low atom utilization rate, and difficult separation of catalysts, and achieve high conversion efficiency, mild reaction conditions, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

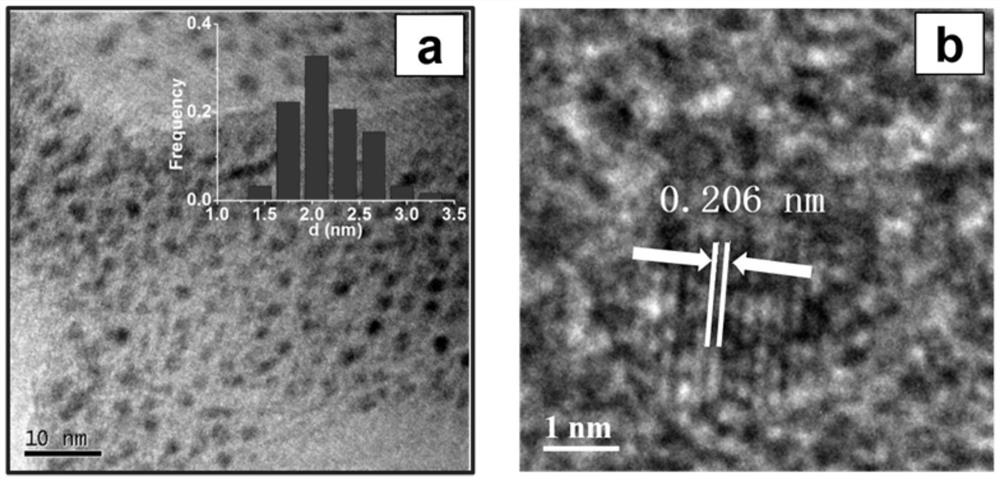

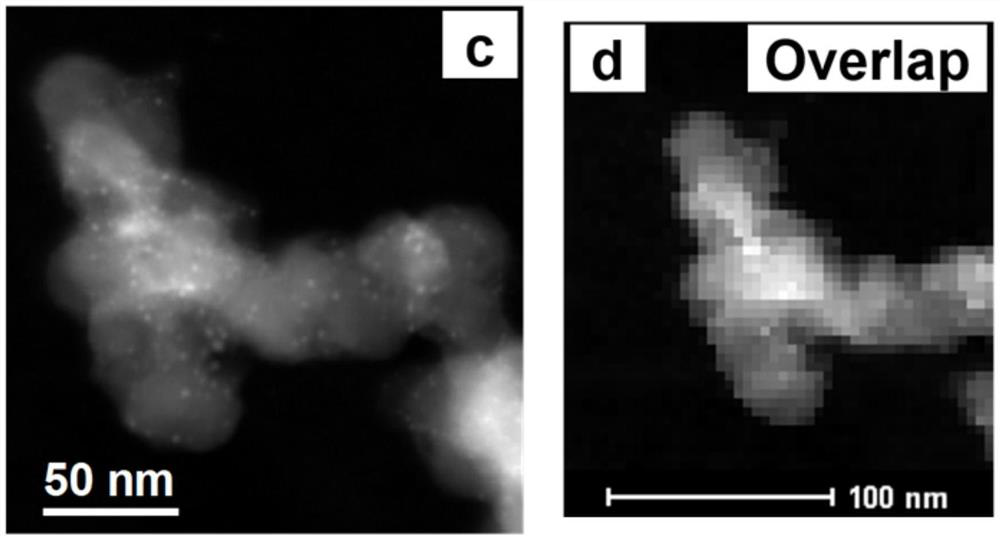

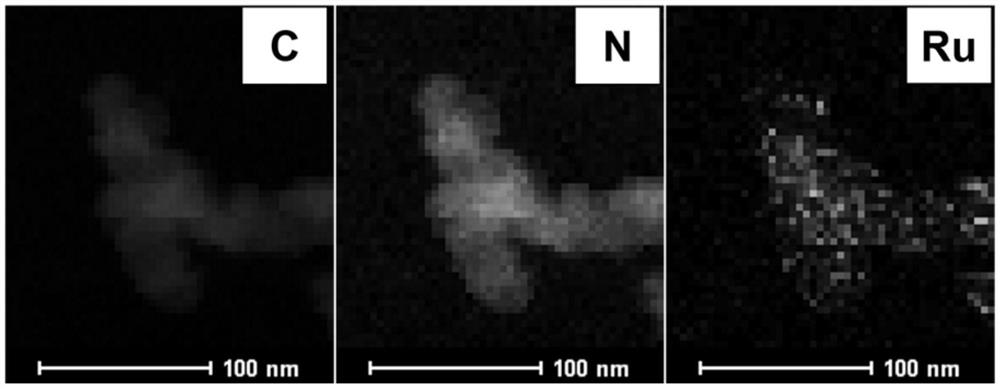

[0031] Embodiment 1: Preparation of carbon-supported ruthenium nanomaterials

[0032] Ru(phen) 2 Cl 2 (0.0520 g), absolute ethanol (40 ml) were added to a 100 ml round bottom flask containing a magnetic stirrer, stirred at room temperature for 30 minutes, and then carbon material (VULCAN XC72R, 1.0000 g) was added to it, and reacted at 60°C 12 hours; after the reaction, ethanol was distilled off under reduced pressure in vacuum, and the solid was dried in an oven at 60° C. for 12 hours. Then, put it in a magnetic boat, place it in a tube furnace, and pass nitrogen gas at room temperature for 30 minutes, then raise it from room temperature to 800 °C at a rate of 5 °C per minute, keep it for 2 hours, and then cool it down to room temperature naturally. Promptly obtain the corresponding carbon-loaded ruthenium nanomaterial, its characterization sees attached Figure 1-4 . Thermogravimetric analysis showed that the loading amount of ruthenium was 1.08% wt, and the ruthenium na...

Embodiment 2

[0033] Example 2: Acceptor-free dehydrogenation coupling reaction of benzyl alcohol and aniline catalyzed by carbon-supported ruthenium nanomaterials

[0034]

[0035] Carbon-supported ruthenium nanomaterials (20 mg) and sodium hydroxide (20 mg) were added to a 25 ml reaction tube with a branched port equipped with a magnetic stirrer, nitrogen gas was pumped repeatedly three times, and benzyl alcohol (1.3 mmol ), aniline (1mmol), toluene (3 ml) and then sealed and heated at 110°C for 24 h; after the reaction, filter to remove the catalyst, add water and ethyl acetate to extract the filtrate, combine the organic phase, dry, Filtration, concentration under reduced pressure, and purification by silica gel column chromatography gave N-benzylideneaniline (90% yield).

[0036] The NMR data of the resulting product are as follows:

[0037] 1 H NMR (400 MHz, DMSO- d 6 , ppm) δ 8.61 (s, 1H), 7.95 (d, J = 5.0 Hz,2H), 7.53 (s, 3H), 7.42 (t, J = 7.5 Hz, 2H), 7.30–7.22 (m, 3H);1...

Embodiment 3

[0041] Example 3: Acceptor-free dehydrogenation coupling reaction of 4-methylbenzyl alcohol and aniline catalyzed by carbon-supported ruthenium nanomaterials

[0042]

[0043] Add 4-methylbenzyl alcohol (1.3 mmol), carbon-supported ruthenium nanomaterials (20 mg), and sodium hydroxide (20 mg) into a 25 ml branched reaction tube equipped with a magnetic stirrer, and pump nitrogen repeatedly Three times, add aniline (1 mmol) and toluene (3 ml) successively through a syringe, and then seal and heat at 110 °C for 24 h; after the reaction, remove the catalyst by filtration, add water and ethyl acetate to extract the filtrate, and combine organic phase, dried, filtered, concentrated under reduced pressure, and purified by silica gel column chromatography to obtain N-(4-methylbenzylidene)aniline (92% yield).

[0044] The NMR data of the resulting product are as follows:

[0045] 1 H NMR (400 MHz, DMSO- d 6 , ppm) δ 8.56 (s, 1H), 7.83 (d, J = 7.8 Hz,2H), 7.41 (t, J = 7.7 Hz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com