Preparation method of fermentation feed by taking bean dregs and rice bran as major raw materials

A technology of fermented feed and main raw materials, which is applied in the field of livestock and poultry feed, can solve the problems that fermented raw materials need to be sterilized and are difficult to implement, and achieve the effects of improving intestinal micro-ecological environment, easy operation, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the fermented feed using bean dregs and rice bran as main raw materials comprises the following steps:

[0037] (1) Preparing a compound enzyme preparation: mixing cellulase, pectinase, papain, and neutral protease in a mass ratio of 1:1:0.5:0.5 to obtain a compound enzyme preparation;

[0038] (2) Preparation of compound enzyme preparation liquid: the compound enzyme preparation and water are mixed in a mass ratio of 1:5 to obtain a compound enzyme preparation liquid;

[0039] (3) Prepare bean curd residue dehydration: dehydrate fresh bean curd residue until the moisture content of bean curd residue is 72%;

[0040] (4) Enzymolysis of bean curd residues: mix bean curd residues and compound enzyme preparation solution at a mass ratio of 1000:0.5, and carry out enzymatic hydrolysis at 50° C. for 0.5 h to obtain enzymatically hydrolyzed bean curd residues;

[0041] (5) Mix the bean curd residue after enzymolysis with fresh full-fat rice bran in ...

Embodiment 2

[0046] The preparation method of the fermented feed using bean dregs and rice bran as main raw materials comprises the following steps:

[0047] (1) Preparing a compound enzyme preparation: mixing cellulase, pectinase, papain, and neutral protease in a mass ratio of 1:1:0.5:0.5 to obtain a compound enzyme preparation;

[0048] (2) Preparation of compound enzyme preparation liquid: the compound enzyme preparation and water are mixed in a mass ratio of 1:5 to obtain a compound enzyme preparation liquid;

[0049] (3) Prepare bean curd residue dehydration: dehydrate fresh bean curd residue until the moisture content of bean curd residue is 70%;

[0050] (4) Enzymolysis of bean curd residues: mix bean curd residues and compound enzyme preparation solution at a mass ratio of 1000:0.5, and carry out enzymatic hydrolysis at 50° C. for 0.5 h to obtain enzymatically hydrolyzed bean curd residues;

[0051] (5) Mix the bean curd residue after enzymolysis with fresh full-fat rice bran in a ...

Embodiment 3

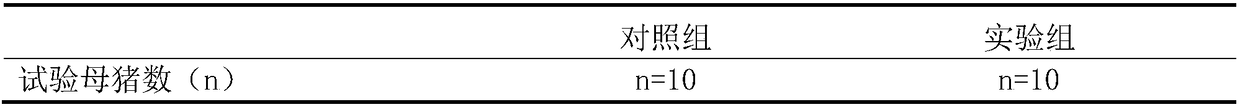

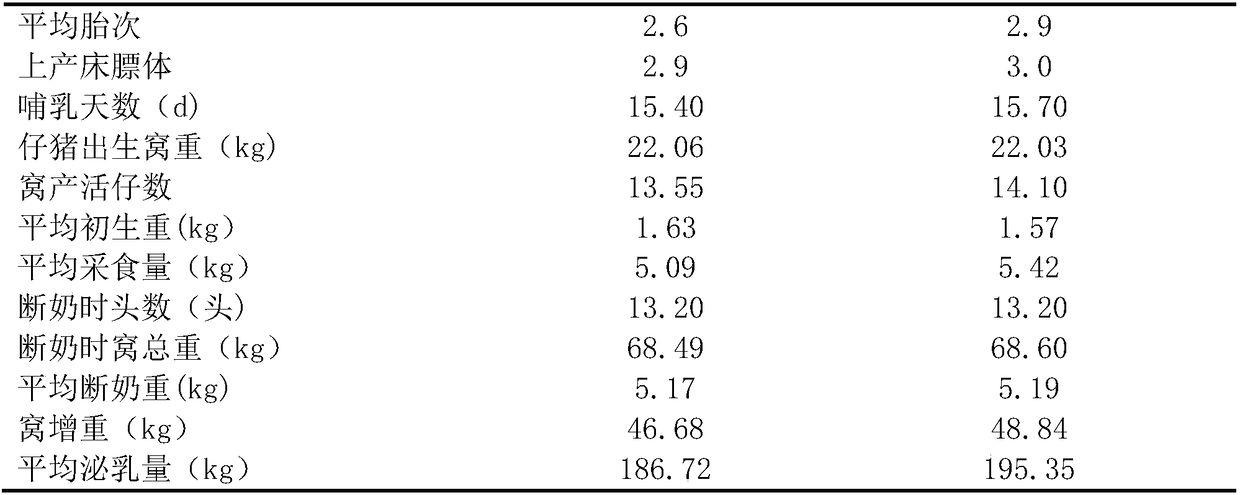

[0056] The fermented feed prepared by Example 1 or 2 of the present invention was additionally added with 5% feed for lactating sows, and the test results are shown in Table 1:

[0057] Table 1

[0058]

[0059]

[0060] Experiments show that the fermented feed prepared by the invention has obvious effects in feed for lactating sows, the average feed intake is increased by 0.33kg / head, and the lactation volume is increased by 8.63kg / head. The rich GABA improves the sow's immunity, reduces the sow's stress response, and the acid-soluble protein is easy to absorb, and the comprehensive effect promotes the increase of milk production. The rich dietary fiber and microbial metabolites in the fermented feed can significantly improve the constipation problem of sows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com