Treatment method for SO2-containing flue gas and treatment device

A sulfur dioxide and treatment method technology, which is applied in the direction of chemical instruments and methods, separation methods, multi-stage water treatment, etc., can solve the problem that the removal effect of sulfur dioxide cannot be guaranteed, and achieve the effects of reducing the treatment load, improving economic benefits, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The process flow of the invention is adopted to treat the selenium-containing wastewater. Wastewater water quality is: pH is 7.3, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2- ) concentration is 3263.2μg / L, selenite ion (SeO 3 2- ) concentration was 2697.3μg / L, COD was 633mg / L, and ammonia nitrogen was 52.4 mg / L. The concentration of sulfur dioxide in the flue gas is 3170mg / m³.

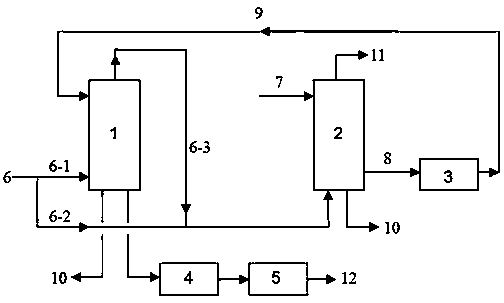

[0030] A two-stage gas-liquid contact desulfurization tower is adopted, and the sulfur dioxide-containing flue gas part enters the first-stage reactor, and reacts with the selenium-containing wastewater discharged from the acidification reactor, and the liquid-gas volume ratio is controlled to be 0.3L / m 3 , to remove selenite ions; the flue gas discharged from the first stage reactor is mixed with the remaining part of the flue gas and then enters the second stage reactor to directly react with selenium-containing wastewater, and the liquid-gas volume r...

Embodiment 2

[0033] The method of the invention is used to treat the selenium-containing wastewater. Wastewater water quality: pH is 6.7, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2- ) concentration is 21228.3μg / L, selenite ion (SeO 3 2- ) concentration was 12757.7μg / L, COD: 682mg / L, ammonia nitrogen: 73.3 mg / L. The concentration of sulfur dioxide in the flue gas is 8630mg / m³.

[0034] A two-stage gas-liquid contact desulfurization tower is adopted, and the sulfur dioxide-containing flue gas part enters the first-stage reactor, and reacts with the selenium-containing wastewater discharged from the acidification reactor, and the liquid-gas volume ratio is controlled to be 0.5L / m 3 , to remove selenite ions; the flue gas discharged from the first stage reactor is mixed with the remaining part of the flue gas and then enters the second stage reactor to directly react with selenium-containing wastewater, and the liquid-gas volume ratio is controlled t...

Embodiment 3

[0037] Treatment process and operating conditions are the same as in Example 2. The difference is that in the acidification reactor, a mixed solution of 50g / L thiourea and 50g / L ascorbic acid is added to the hydrochloric acid solution. After treatment, the removal rate of total selenium reached 95.2%, the removal rate of COD was 91.4%, and the removal rate of ammonia nitrogen was 90.1%. The removal rate of sulfur dioxide in flue gas is 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com