Preparation method of nickel sulfide/graphene-like carbonitride composite catalyst

A technology of alkene carbonitride compound and composite catalyst, which is applied in the fields of material science and photocatalytic hydrogen production, and achieves the effects of excellent hydrogen production activity and stability, simple and efficient method and large number of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Weigh 20g of thiourea and put it into a crucible to add a cover, heat it under 550°C air atmosphere for 2 hours, and the heating rate is 2°C / min. After grinding the obtained yellow powder, put it into an uncovered crucible, Heating at 500°C for 2 hours, the heating rate is still 2°C / min. Finally, the obtained light yellow powder is graphene-like carbon nitrogen compound;

[0019] (2) In a 25mL single-necked round bottom flask, add 20mg of graphene-like carbonitride, 12.5mg of nickel acetate, 38mg of thiourea, 4mL of absolute ethanol, 6mL of ultrapure water, and ultrasonically treat for 5 minutes to disperse and mix evenly. Nitrogen was introduced for 40 minutes to remove oxygen in the reaction system.

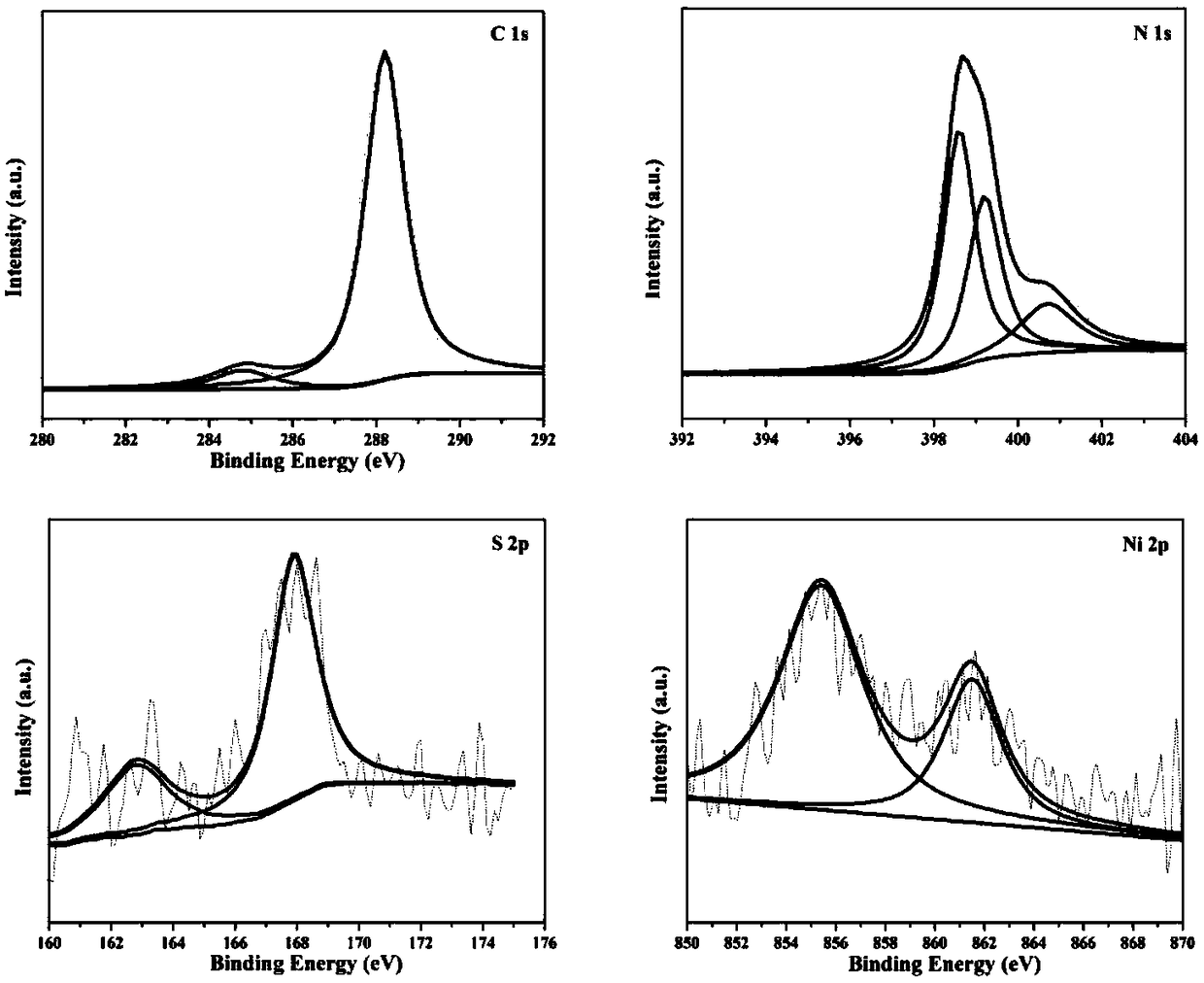

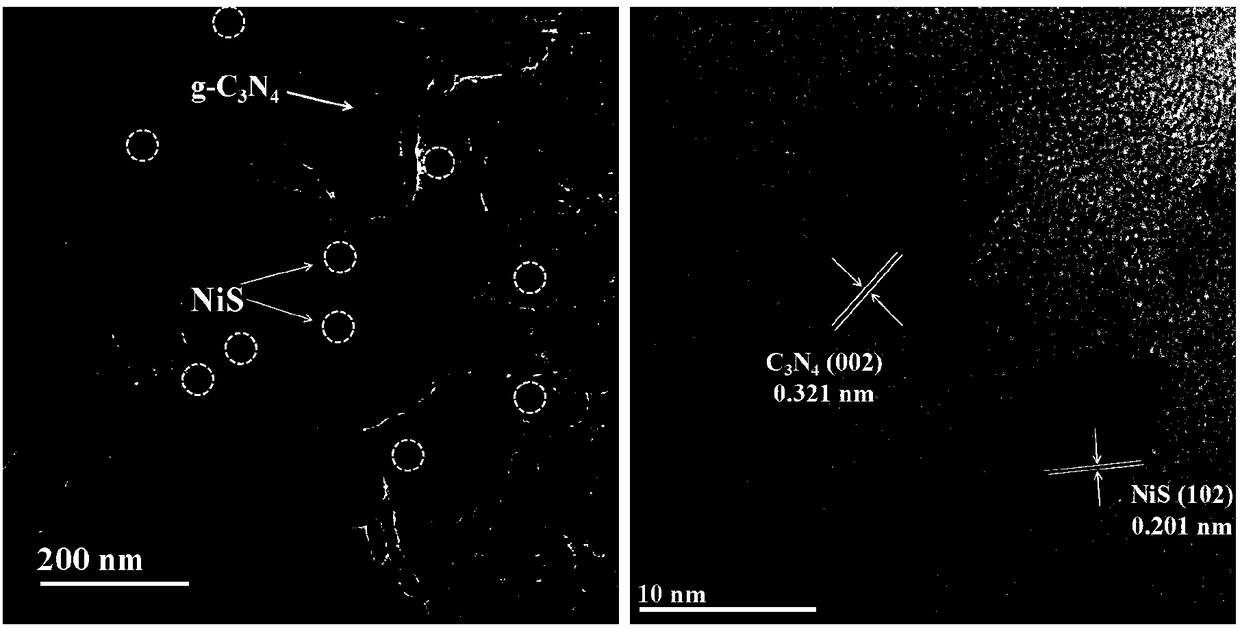

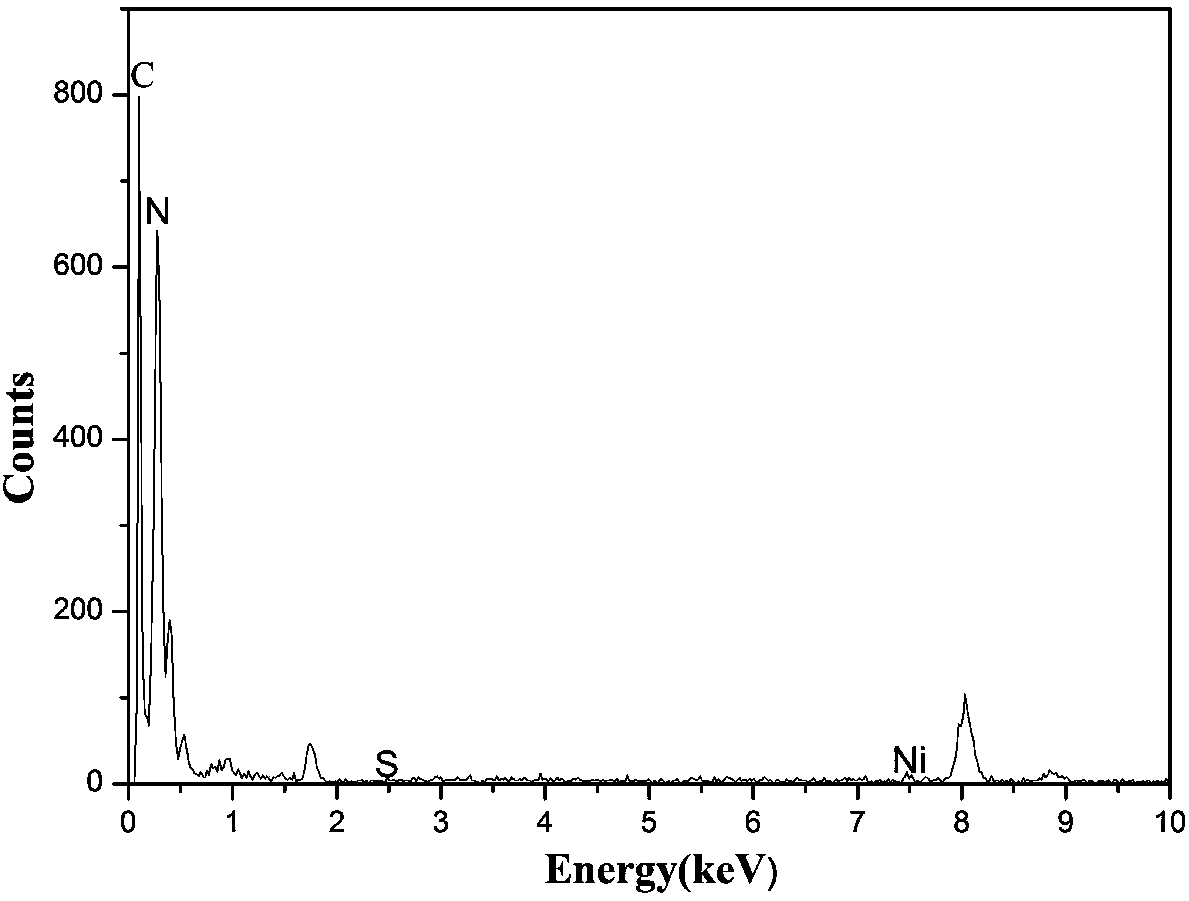

[0020] (3) Place the flask under a 300W xenon lamp, and after irradiating for 20 minutes, use centrifugation to separate the solid, wash twice with deionized water, and once with ethanol, put the obtained solid in a vacuum drying oven, and dry overnight at 80°C to ob...

Embodiment 2

[0023] Get nickel sulfide / graphene-like carbonitride compound catalyst 5mg prepared in embodiment 1 and place in 25mL round bottom flask, add 1mL triethanolamine (98%), 9mL water; Ultrasonic treatment 5min, remove reaction with nitrogen degassing 40min Oxygen in the system; the round-bottomed flask is placed in a 300W xenon lamp, illuminated under a 400nm filter, and after the reaction is over, detect the hydrogen generated by the reaction with a thermal conductivity-gas chromatograph. The hydrogen production rate of this catalyst is about 800 μmol g -1 h -1 , and after 30 hours of reaction, the hydrogen production rate did not significantly decrease ( Figure 4 ).

Embodiment 3

[0025] Get nickel sulfide / graphene-like carbonitride composite catalyst 5mg prepared in embodiment 1 and place in 25mL round bottom flask, add 1mL triethanolamine (98%), 9mL water; Ultrasonic treatment 5min, remove reaction with nitrogen degassing 40min Oxygen in the system; put the round bottom flask under natural sunlight for 2 hours, and the hydrogen production rate is about 1000μmol g -1 h -1 ( Figure 5 ).

[0026] As can be seen from the above examples, the nickel sulfide / graphene-like carbonitride composite catalyst prepared by the present invention has the advantages of simple synthesis method, high hydrogen production rate, good stability, etc., and has a good application in the field of photocatalytic hydrogen production. Industrial application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com