Low-hardness, high-resilience, low-melting-point thermoplastic polyurethane elastomer and its preparation method and application

A thermoplastic polyurethane, high-resilience technology, applied in the field of thermoplastic polyurethane elastomers, can solve the problems of low resilience and inability to process films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

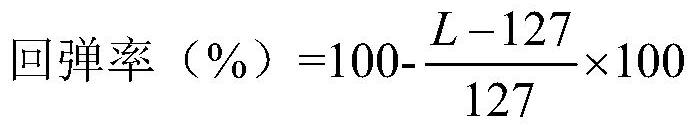

Method used

Image

Examples

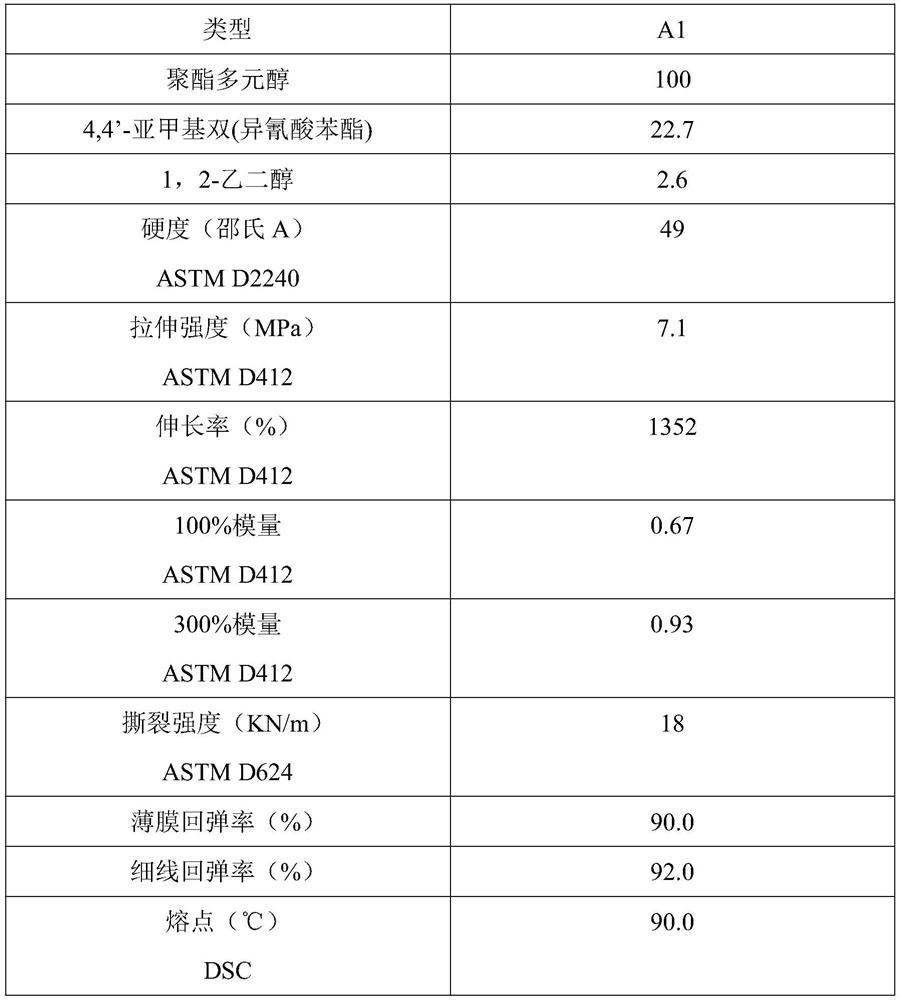

Embodiment 1

[0066] (A) Polyester polyol:

[0067] The molar ratio of 1,4-butanediol, 1,6-hexanediol, and 1,1,1-tri(hydroxymethyl)propane is 2:100:1;

[0068] The catalyst is stannous octoate, and the molar amount is 0.0002% of the molar amount of 1,4-butanediol;

[0069] Preparation:

[0070] React 1,4-butanediol, 1,6-hexanediol, 1,1,1-tri(hydroxymethyl)propane, 1,6-hexanedioic acid and catalyst at 140°C for 20 hours, remove Water, can obtain described polyester polyol, number average molecular weight is 2000;

[0071] The (A) polyester polyol is heated to 110°C;

[0072] Heat (B) 4,4'-methylenebis(phenylisocyanate) to 60°C;

[0073] (C) 1,2-ethanediol is heated to 60°C;

[0074] Send component (A), component (B) and component (C) into the mixing head for mixing, then pour into the twin-screw extruder for reaction and extrusion, and then pelletize under water to remove the obtained particles Moisture, ripening, can obtain described low hardness high resilience low melting point ther...

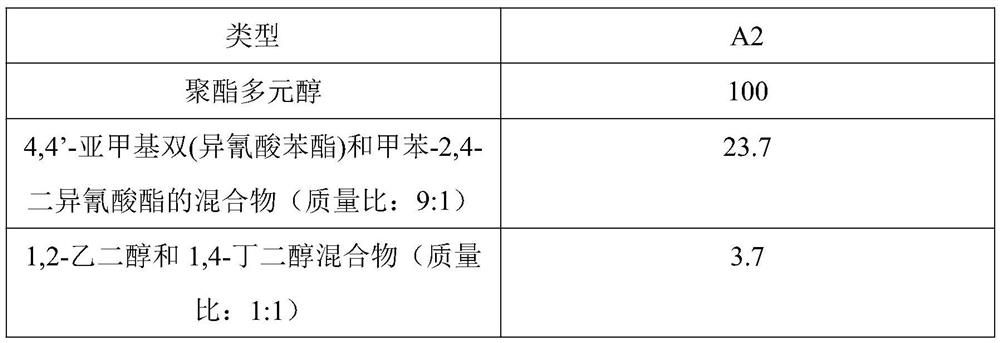

Embodiment 2

[0083] (A) Polyester polyol:

[0084] Components and ratio:

[0085] The molar ratio of 1,4-butanediol, 1,6-hexanediol, and 1,2,3-propanetriol is 200:100:6;

[0086] The catalyst is stannous octoate, and the molar amount is 0.001% of the molar amount of 1,4-butanediol;

[0087] Preparation:

[0088] React 1,4-butanediol, 1,6-hexanediol, 1,2,3-propanetriol, 1,6-hexanedioic acid, catalyst and additives at 150°C for 24 hours, remove water in vacuum , the polyester polyol can be obtained, and the number average molecular weight is 2000;

[0089] Described auxiliary agent is:

[0090] Antioxidant 1010 adopts the Irganox 1010 brand product of BASF, and the weight consumption is 0.005% of 1,4-butanediol weight;

[0091] The lubricant polyethylene wax is H110 brand product of Haihao Company, and the weight dosage is 0.006% of the weight of 1,4-butanediol;

[0092] The (A) polyester polyol is heated to 120°C;

[0093] (B) a mixture of 4,4'-methylenebis(phenylisocyanate) and tolu...

Embodiment 3

[0105] (A) Polyester polyol:

[0106] Components and ratio:

[0107] The molar ratio of 1,4-butanediol, 1,6-hexanediol, and 1,1,1-tris(hydroxymethyl)ethane is 100:100:4;

[0108] The catalyst is dibutyltin dilaurate, and the molar dosage is 0.02% of the molar dosage of 1,4-butanediol;

[0109] Preparation:

[0110] React 1,4-butanediol, 1,6-hexanediol, 1,1,1-tri(hydroxymethyl)ethane, 1,6-adipic acid, catalyst and additives at 120°C for 16 Hour, vacuum dewatering, can obtain described polyester polyol, number-average molecular weight is 2000;

[0111] Antioxidant 1010 adopts the Irganox 1010 brand product of BASF, and the weight consumption is 0.005% of 1,4-butanediol weight;

[0112] The anti-ultraviolet light agent UV-328 adopts the Tinuvin328 brand product of BASF Company, and the weight dosage is 0.006% of the molar weight of 1,4-butanediol,

[0113] The lubricant polyethylene wax is H110 brand product of Haihao Company, and the weight dosage is 0.005% of the molar amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com