Method for cladding UCNPs (upconversion nanoparticles) through low-temperature cyclodextrin carbonization

A nanoparticle and cyclodextrin technology, which is applied in the field of nano-fluorescent materials, can solve the problems of difficult control of the thickness of the coating carbonization layer, cumbersome operation process, and fluorescence quenching, so as to achieve improved biocompatibility, simple preparation process, and reduced biotoxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Prepare 50mg cyclodextrin and 40ml deionized water, and mix them to form the first mixture;

[0026] 2. Prepare 20 mg of up-conversion nanocrystals with a particle size of 100 nanometers, and disperse them in cyclohexane to form a second mixed solution;

[0027] 3. Mix the first and second mixed liquids and stir thoroughly for 2 hours to obtain the third mixed liquid;

[0028] 4. Heat the third mixed solution to 60°C, keep it for 80 minutes to evaporate and remove the cyclohexane, and cool to obtain a transparent aqueous solution;

[0029] 5. Add the aqueous solution into a polytetrafluoroethylene reactor, and react at 160 degrees Celsius for 16 hours under airtight conditions;

[0030] 6. The obtained product is centrifuged and washed several times, and dried to obtain a carbon-coated upconversion nanomaterial.

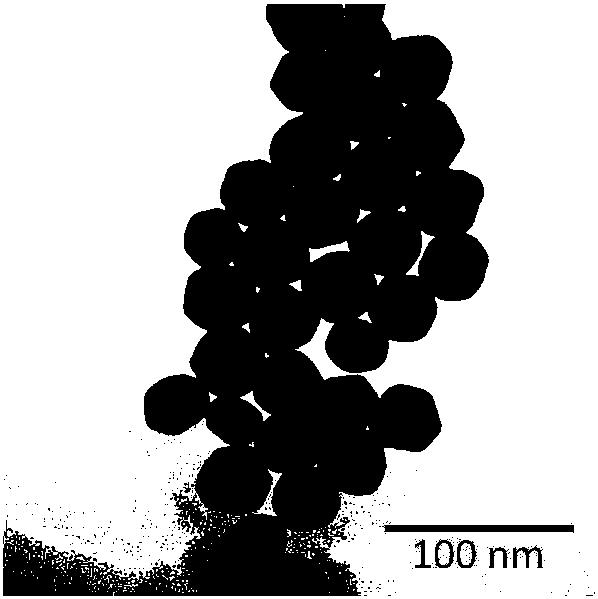

[0031] like Figure 1-2 Shown: It can be seen that there is a thin layer of carbon coated on the surface of up-conversion nanocrystals NaYF4:Yb,Er.

Embodiment 2~7

[0033] As in Example 1, the volume of the reaction solution, the temperature, and the time operating conditions are constant, and the quality of the cyclodextrin and the up-conversion quality are changed to test: the specific information is as follows:

[0034] serial number

Cyclodextrin quality

Upconversion Quality

Example 2

100mg

20mg

Example 3

200mg

20mg

Example 4

300mg

20mg

Example 5

400mg

20mg

Example 6

500mg

20mg

Example 7

600mg

20mg

[0035] like figure 1 and figure 2 The comparison shows: It can be seen that there is a thin layer of carbon coated on the surface of the up-conversion nanocrystal NaYF4:Yb, Er.

[0036] The prepared cyclodextrin carbon coating layer effectively reduces the biological toxicity, improves its biocompatibility, and can prevent the agglomeration of nanoparticles. The preparation process is simple, and it is beneficial to further mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com