Preparation method and application of tobacco cationic hemicellulose

A hemicellulose and cationic technology, applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of general effect, small size, and small force, and achieve the effects of reducing load, improving filler retention rate, and improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

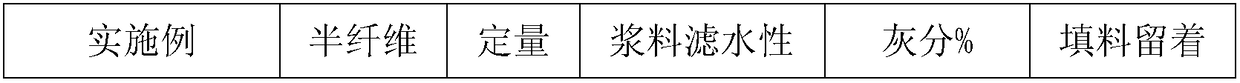

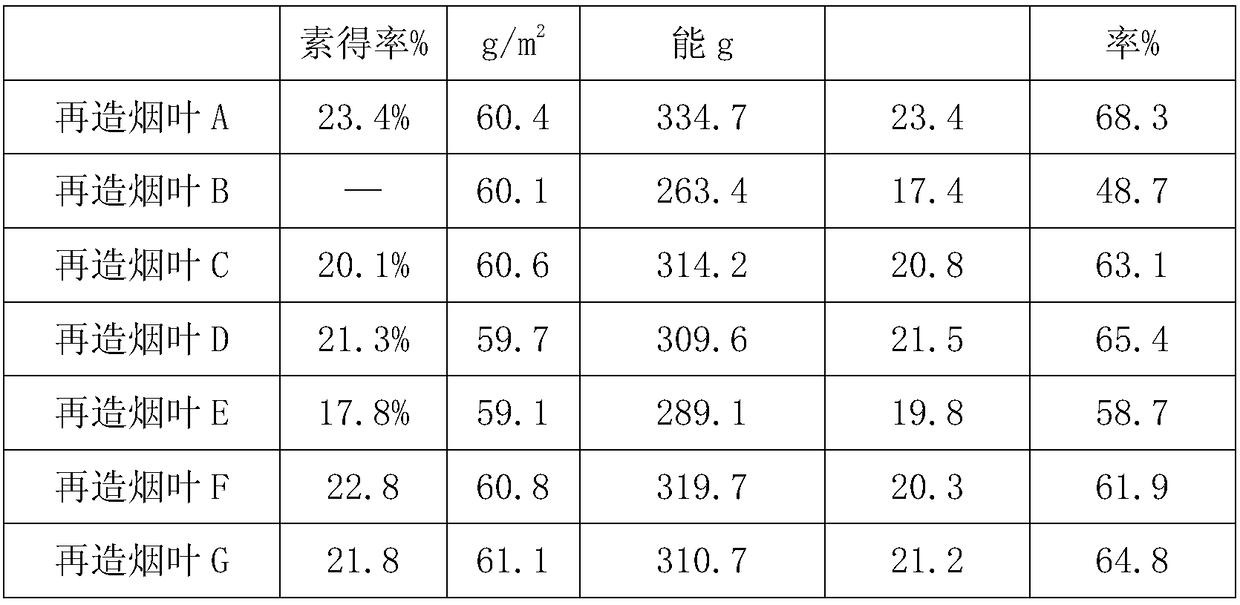

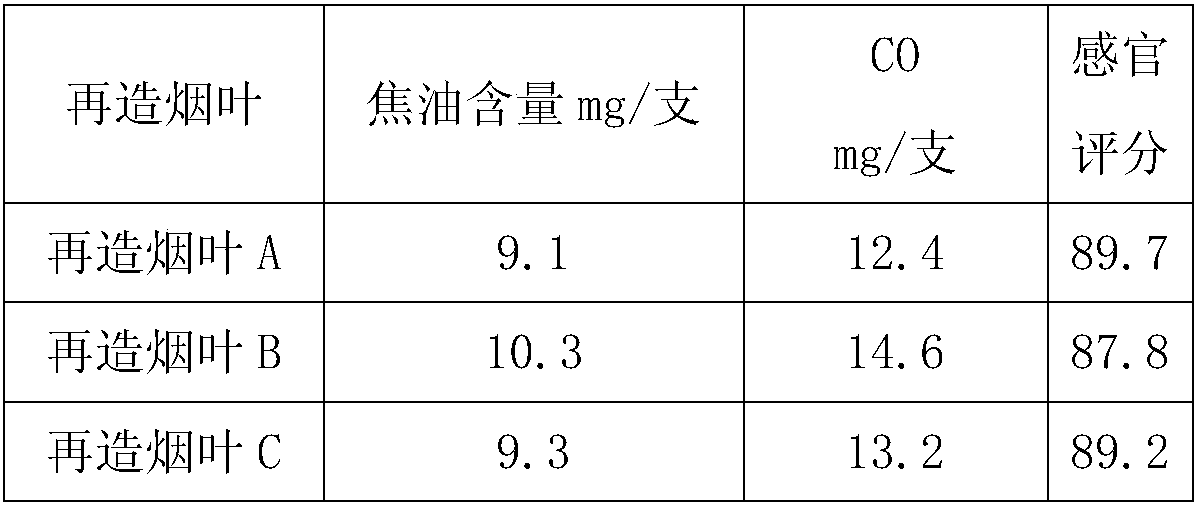

Examples

Embodiment 1

[0024] Embodiment 1, a kind of preparation method of tobacco cationic hemicellulose is characterized in that the specific preparation steps are as follows:

[0025] (1) Add 10 times the amount of water to the discarded tobacco stems, tobacco leaf fragments, tobacco powder, etc., extract at 65°C for 4 hours, collect the solid phase after filtration, and take 10 parts by weight of the solid phase and 100 parts by weight of the mass fraction 6 % sodium hydroxide solution is mixed and put into a reactor with a stirring device and a heating system, and the temperature is raised to 80° C., and at the same time, under the condition of a rotating speed of 800 rpm, after stirring and reacting for 3 hours, oxalic acid is added to neutralize to pH 6.5, Filtrate, collect the filtrate and add 3 times the volume of 95% ethanol to precipitate the soluble hemicellulose, collect the precipitate after filtration, dry it, and obtain tobacco hemicellulose;

[0026] (2) Put 10 parts by weight of t...

Embodiment 2

[0029] Embodiment 2, a kind of preparation method of tobacco cationic hemicellulose is characterized in that the specific preparation steps are as follows:

[0030](1) add discarded tobacco stems, tobacco leaf fragments, and tobacco powder to 13 times the weight of water and extract at 60°C for 4 hours, collect the solid phase after filtration, and take 10 parts by weight of the solid phase and 90 parts by weight of the Mix potassium hydroxide solution with a mass fraction of 8% and put it into a reactor with a stirring device and a heating system, raise the temperature to 65°C, and at the same time, stir and react for 2 hours at a speed of 600rpm, then add oxalic acid to neutralize to pH5 .5, filter, add the 95% ethanol of its 3 times of volume in the filtrate, add the ethanol of its concentration 95% of 3 times of volume in the filtrate, make the precipitation of soluble hemicellulose, and collect the precipitate after filtering, Dried to obtain tobacco hemicellulose;

[00...

Embodiment 3

[0033] Embodiment 3: a kind of preparation method of tobacco cationic hemicellulose is characterized in that the specific preparation steps are as follows:

[0034] (1) add discarded tobacco stems, tobacco leaf fragments, and tobacco powder to 8 times the weight of water to extract at 75°C for 3 hours, collect the solid phase after filtration, and take 10 parts by weight of the solid phase and 120 parts by weight of the mass Mix 12% potassium hydroxide solution into a reactor with a stirring device and a heating system, raise the temperature to 90°C, and at the same time, stir and react for 3.5 hours at a speed of 1000rpm, then add acetic acid to neutralize to pH7 .0, filter, and add 3 times its volume of ethanol with a concentration of 95% to the filtrate to precipitate the soluble hemicellulose, and collect the precipitate after filtration, dry it to obtain tobacco hemicellulose;

[0035] (2) Put 10 parts by weight of the tobacco hemicellulose prepared in step (1) into a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com