Low-pollution flame-retardant thermal expansion microspheres and preparation method thereof

A heat-expandable microsphere, flame-retardant technology, applied in flame-retardant fibers, textiles and papermaking, fiber processing, etc., to achieve the effect of improving flame-retardant efficiency, low pollution, and high-efficiency flame-retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

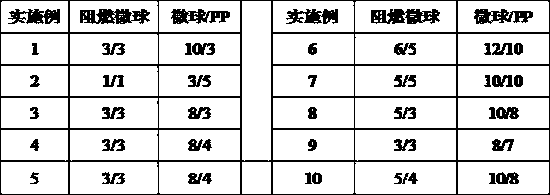

Examples

Embodiment 1

[0056] Add 270g deionized water, 10g sodium hydroxide, 30g magnesium chloride hexahydrate, 1wt% sodium lauryl sulfate aqueous solution 4g and 35g sodium chloride in 500ml three-necked flask, at 1000r / min Stir vigorously under the same conditions for 30 minutes to obtain an aqueous phase protection solution.

[0057] The reaction is water phase polymerization, and the oil phase reaction liquid droplets can react in a spherical shape in the water phase, so that the shape of the foamed microspheres is circular.

[0058] Add 60g of acrylonitrile, 36g of methyl methacrylate, 24g of vinyl acetate, 20g of n-hexane, 16g of trioctyl phosphate, 3g of azobisisobutyronitrile, 0.48g of ethylene glycol diformic acid acrylate, and 3 g of benzene and 60 g of KH570 modified magnesium hydroxide micron particles were mixed uniformly to obtain an oil phase.

[0059] KH570 modified magnesium hydroxide micron particles: it is the surface modified hydroxide in the shell material components. It is ...

Embodiment 2

[0063] On the basis of Example 1, the raw materials of the oil phase were changed to: 60g of acrylonitrile, 36g of methyl methacrylate, 24g of vinyl acetate, 36g of tributyl phosphate, 3g of azobisisobutyronitrile, ethylene glycol di 0.48 g of formic acid acrylate, 2 g of ethylene glycol di(meth)acrylate, and 40 g of KH570 modified magnesium hydroxide nanoparticles were uniformly mixed to obtain an oil phase.

[0064] Other similar operations.

Embodiment 3

[0066] On the basis of Example 1, the oil phase raw materials were changed into: 60g of acrylonitrile, 36g of methyl methacrylate, 24g of vinyl acetate, 30g of pyrophosphate, 10g of isooctane, 3g of azobisisobutyronitrile, and 0.48 g of diol diformic acid acrylate, 6 g of di(ethylene glycol) di(meth)acrylate, and 60 g of KH560 modified magnesium hydroxide micron particles were uniformly mixed to obtain an oil phase.

[0067] Other similar operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com