Preparation method of high-strength and anti-static fiber reinforced plastic material

An antistatic and glass fiber reinforced plastic technology is applied in the field of polymer material preparation, which can solve the problems of spontaneous combustion, spark generation, and static electricity generation of materials, and achieve the effects of improving high temperature resistance, decreasing resistance and improving antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

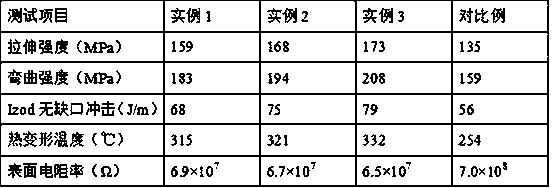

Examples

example 1

[0022]Weigh 80g of wollastonite and put it into a high-temperature furnace, calcinate at 850°C for 1 hour, grind and discharge the material to obtain calcined wollastonite powder, and mix the calcined wollastonite powder and deionized water at a mass ratio of 1:3 Place in a four-necked flask equipped with a thermometer, a condenser and a stirrer, and stir for 10 minutes in an ice-water bath at 0°C. After stirring, add 2 mL of anhydrous tin tetrachloride dropwise to the four-necked flask, and continue stirring for 24 minutes. The reaction solution was obtained, and the pH value of the reaction solution was adjusted to 8-10 with ammonia water with a mass fraction of 15%. After adjustment, the temperature was raised to 25° C., and kept for 35 minutes to obtain a precipitate, and the filtrate was filtered to obtain a filter residue, which was washed with deionized water. Filter the residue 3 times, and finally put it into an oven, dry it at 75°C for 20 minutes, put it into a high-t...

example 2

[0024] Weigh 90g of wollastonite and put it into a high-temperature furnace, calcinate at 900°C for 1.5h, grind and discharge the material to obtain calcined wollastonite powder, and mix the calcined wollastonite powder and deionized water in a mass ratio of 1:3 Mix and place in a four-necked flask equipped with a thermometer, a condenser and a stirrer, and stir for 11 minutes in an ice-water bath at 0°C. After stirring, add 3 mL of anhydrous tin tetrachloride dropwise to the four-necked flask, and continue stirring for 28 minutes. , to obtain the reaction solution, adjust the pH value of the reaction solution to 9 with ammonia water with a mass fraction of 15%, heat up to 30°C after adjustment, and keep it warm for 40min to obtain a precipitate, filter the filtrate to obtain a filter residue, wash the filter residue with deionized water 4 times, finally put it into an oven, dry at 80°C for 25 minutes, put it into a high-temperature furnace after drying, continue to calcinate a...

example 3

[0026] Weigh 100g of wollastonite and put it into a high-temperature furnace, calcinate at 950°C for 2 hours, grind and discharge the material to obtain calcined wollastonite powder, and mix the calcined wollastonite powder and deionized water at a mass ratio of 1:3 Place in a four-necked flask equipped with a thermometer, a condenser and a stirrer, and stir for 12 minutes in an ice-water bath at 0°C. After stirring, add 4 mL of anhydrous tin tetrachloride dropwise to the four-necked flask, and continue stirring for 32 minutes. The reaction solution was obtained, and the pH value of the reaction solution was adjusted to 8-10 with ammonia water with a mass fraction of 15%. After adjustment, the temperature was raised to 35° C., and kept for 45 minutes to obtain a precipitate, and the filtrate was filtered to obtain a filter residue, which was washed with deionized water. Filter the residue 5 times, and finally put it into an oven, dry it at 85°C for 30 minutes, put it into a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com