Preparation method of a transplantable scaffold for inducing circulating tumor cell metastasis

A technology of tumor cells and induced circulation, which is applied in the direction of drug devices and other medical devices, can solve the problems of exosomes that cannot be used in structure, drug loading and sustained release, and bioactive molecule inactivation, etc., to achieve non-degradability Good, overcoming the difficulty of transplantation, good denaturation and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

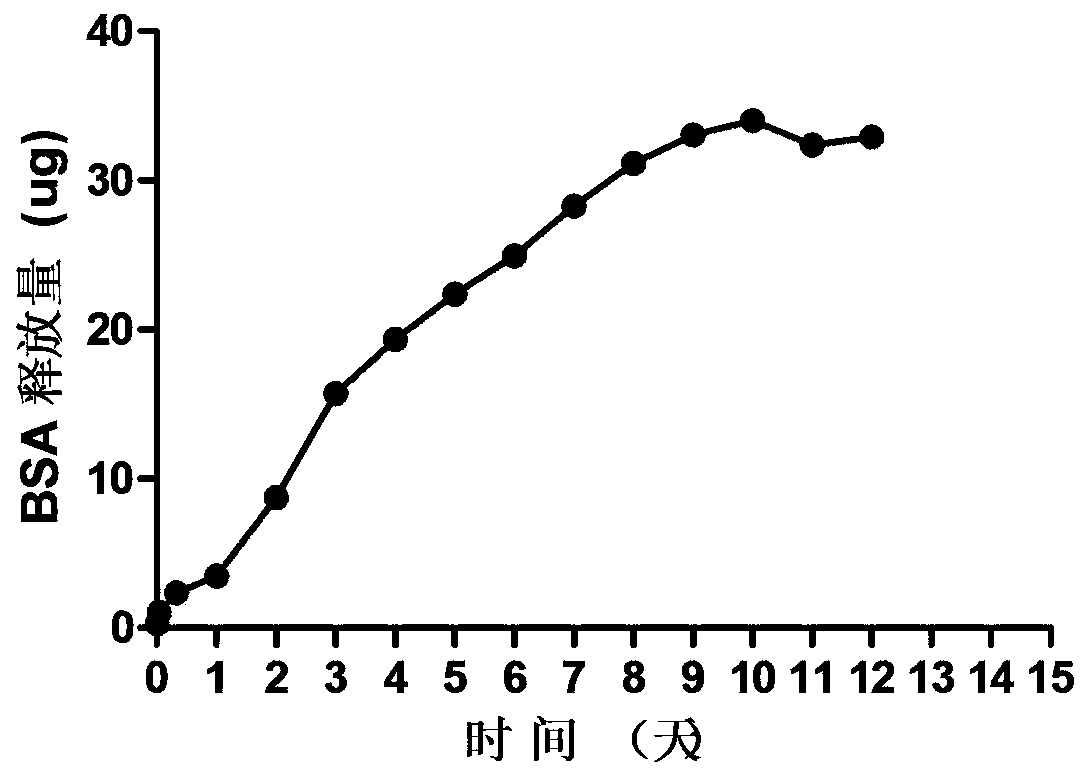

[0030] see figure 1 , mix PDMS and curing agent according to 10:1, drop it on the cover glass, put it on the coating machine and spin coat it for 90s, the speed is 400rpm / min, heat at 60°C for 20min, and the PDMS is cured; the cured PDMS is sprayed with plasma The exosomes were treated for 1 min; the polyallylamine hydrochloride solution was added dropwise on the surface of the PDMS membrane, 400rpm / min spin-coated for 90s, then water was added dropwise, 2000rpm / min spin-coated for 60s, and then the PBS solution containing exosomes was sprayed, and then added dropwise Polystyrene sulfonate aqueous solution was spin-coated at 400rpm / min for 90s, then water was added dropwise, and spin-coated at 2000rpm / min for 60s, and this was cycled 20 times to form layer-by-layer self-assembled membranes loaded with exosomes on the PDMS surface. Wherein polystyrene sulfonate, polypropylene amine hydrochloride aqueous solution, concentration 5g / L, add 0.15M sodium chloride, adjust pH value to...

Embodiment 2

[0033] Mix PDMS and curing agent 15:1, drop it on the cover glass, put it on the coating machine and spin coat it for 30s, the rotation speed is 5000rpm / min, heat at 120°C for 20min, and the PDMS is cured; the cured PDMS is treated with plasma 10min; Add polylysine solution dropwise on the surface of PDMS membrane, spin-coat at 3000rpm / min for 40s, then add water dropwise, spin-coat at 3000rpm / min for 40s, then spray PBS solution containing exosomes, then add hyaluronic acid aqueous solution dropwise, Spin-coat at 3000rpm / min for 40s, then add water dropwise, spin-coat at 3000rpm / min for 40s, cycle 100 times, and form layer-by-layer self-assembled films loaded with exosomes on the surface of PDMS. Wherein hyaluronic acid, polylysine aqueous solution, concentration 1g / L, add 0.15M sodium chloride, adjust pH value to be 3.

[0034] The PDMS membrane was peeled off from the substrate, sterilized with hexane oxide gas, and implanted into the omentum fat pad.

Embodiment 3

[0036] Mix PDMS and curing agent 10:1, drop it on the cover glass, put it on the coating machine and spin coat it for 90s, the rotation speed is 3000rpm / min, heat at 100°C for 20min, and the PDMS is cured; the cured PDMS is treated with plasma 5min; Add chitosan aqueous solution dropwise on the surface of PDMS membrane, spin-coat at 4000rpm / min for 20s, then add water dropwise, spin-coat at 4000rpm / min for 20s, then spray PBS solution containing exosomes, then add hyaluronic acid aqueous solution dropwise, 4000rpm / min spin coating for 20s, then add water dropwise, 4000rpm / min spin coating for 20s, and cycle 50 times in this way to form layer-by-layer self-assembled films loaded with exosomes on the surface of PDMS. Wherein hyaluronic acid, chitosan aqueous solution, concentration 2g / L, add 0.15M sodium chloride, adjust pH value to be 3.

[0037] The PDMS membrane was peeled off from the substrate, sterilized with hexane oxide gas, and implanted into the omentum fat pad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com