Carbon-based supercapacitor electrode material and preparation method thereof

A technology of supercapacitor electrodes and carbon materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of difficult preparation, limitation, and high price, and achieve high specific capacitance per unit mass, high specific capacity, Good effect of fast charging and discharging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The supramolecular dopant content is zero.

[0046] Take 0.12mmol of pyrrole and add 1ml of isopropanol, and record it as solution A; take 1.2mmol of ammonium persulfate and add deionized water to obtain solution B; refrigerate solution A and solution B to 4 degrees Celsius, mix, and stand for 30 minutes; immerse the reaction product in Ethanol solution for 12 hours, filtered to remove excess pyrrole, then immersed in deionized water for 24 hours, filtered to remove excess supramolecular dopant; after drying, black solid powder of doped polypyrrole was obtained. In a nitrogen atmosphere, carbonization under normal pressure, the nitrogen flow rate is 70 sccm, the heating rate is from 5 degrees Celsius to 800 degrees Celsius, and the temperature is naturally lowered after maintaining for 2 hours. The carbonized material was immersed in 7M KOH solution for 24 hours, filtered and dried; in a nitrogen atmosphere, under normal pressure, the nitrogen flow rate wa...

Embodiment 2

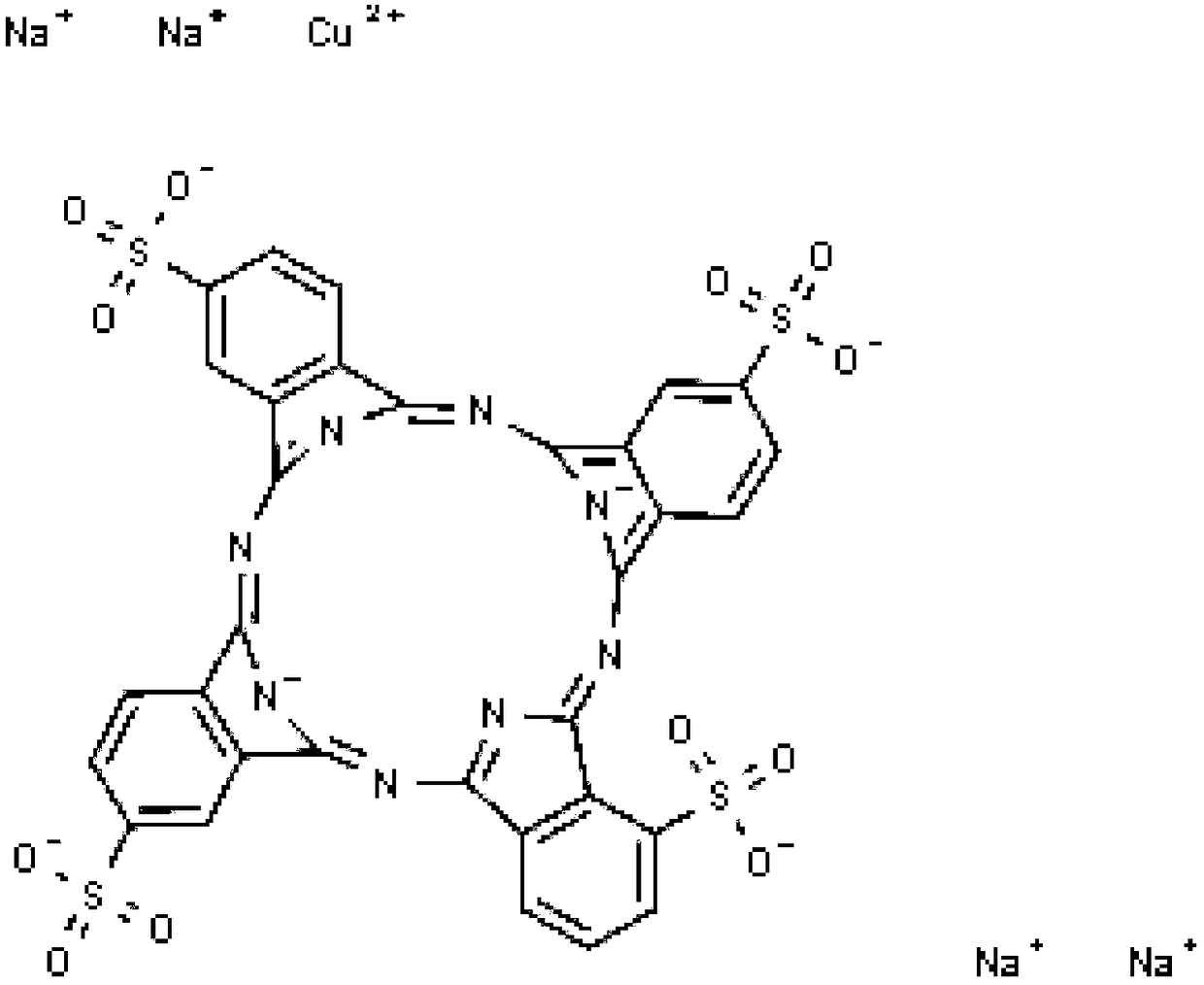

[0047] Example 2: Copper phthalocyanine is used as a supramolecular dopant and pressed into a film.

[0048] Take 0.12mmol of pyrrole and add 1ml of isopropanol, and record it as solution A; take 0.030mmol of copper phthalocyanine and add 2ml of deionized water to obtain a doping solution, then take 1.2mmol of ammonium persulfate and add it to the doping solution to obtain solution B; refrigerate solution A and solution B to 4 degrees Celsius, mix, and stand for 30 minutes; immerse the reaction product in ethanol solution for 12 hours, filter to remove excess pyrrole, and then immerse in deionized water for 24 hours, filter to remove excess supramolecular dopant; dry to obtain doped Polypyrrole black solid powder. In a nitrogen atmosphere, carbonization under normal pressure, the nitrogen flow rate is 70 sccm, the heating rate is from 5 degrees Celsius to 800 degrees Celsius, and the temperature is naturally lowered after maintaining for 2 hours. The carbonized material was i...

Embodiment 3

[0049] Embodiment 3: Copper phthalocyanine is used as a supramolecular dopant, which is drop-coated on carbon cloth.

[0050] Take 0.12mmol of pyrrole and add 1ml of isopropanol, and record it as solution A; take 0.030mmol of copper phthalocyanine and add 2ml of deionized water to obtain a doping solution, then take 1.2mmol of ammonium persulfate and add it to the doping solution to obtain solution B; refrigerate solution A and solution B to 4 degrees Celsius, mix, and stand for 30 minutes; immerse the reaction product in ethanol solution for 12 hours, filter to remove excess pyrrole, and then immerse in deionized water for 24 hours, filter to remove excess supramolecular dopant; dry to obtain doped Polypyrrole black solid powder. In a nitrogen atmosphere, carbonization under normal pressure, the nitrogen flow rate is 70 sccm, the heating rate is from 5 degrees Celsius to 800 degrees Celsius, and the temperature is naturally lowered after maintaining for 2 hours. The carboniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com