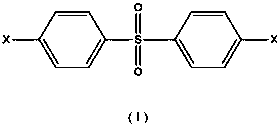

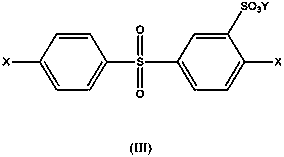

Production method of disulfonated dihalogenated diphenylsulfone

A technology of disulfonated dihalogenated diphenyl sulfone and dihalogenated diphenyl sulfone, which is applied in the field of chemical synthesis and polymer material application, and can solve problems such as difficult molecular weight control, high-purity sulfonated mono To solve the problem of high bulk cost, achieve high solubility, fast reaction speed, improve the success rate of polymerization and control the effect of polymer molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the production of disulfonated 4,4'-dichlorodiphenyl sulfone

[0032] In a dry 20-liter airtight reactor with mechanical stirring and bubbler, add raw materials sequentially, 2872 grams of 4,4'-dichlorodiphenyl sulfone, and prepare 14% sulfur trioxide after calibration by acid-base titration Fuming concentrated sulfuric acid 12010 grams. Stir mechanically to 60 rpm, and gradually heat up the oil bath. When the temperature in the reactor rises to about 75 degrees Celsius, the 4,4'-dichlorodiphenyl sulfone is completely dissolved. Continue to increase the oil bath temperature until the temperature in the reactor is 160 degrees Celsius, increase the stirring speed to 80 rpm; keep the temperature in the reactor at 160 degrees Celsius to continue the homogeneous reaction for 4.5 hours, stop heating, and cool. After the temperature in the reactor drops to 45 degrees Celsius, add about 9000 grams of sodium hydroxide to gradually neutralize to pH ~ 8-9 under the...

Embodiment 2

[0033] Embodiment 2: the production of disulfonated 4,4'-difluorodiphenyl sulfone

[0034] In a dry 20-liter airtight reactor with mechanical stirring and bubbler, add raw materials sequentially, 2543 grams of 4,4'-difluorodiphenyl sulfone, and prepare 14% sulfur trioxide after calibration by acid-base titration Fuming concentrated sulfuric acid 12010 grams. Stir mechanically to 60 rpm, and gradually heat up the oil bath. When the temperature in the reactor rises to about 70 degrees Celsius, the 4,4'-difluorodiphenyl sulfone is completely dissolved. Continue to increase the oil bath temperature until the temperature in the reactor is 158 degrees Celsius, increase the stirring speed to 80 rpm; keep the temperature in the reactor at 158 degrees Celsius to continue the homogeneous reaction for 4 hours, stop heating, and cool. After the temperature in the reactor drops to 45 degrees Celsius, about 13,000 grams of potassium hydroxide is added to gradually neutralize the pH to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com