Fiber bragg grating temperature/strain sensing system and demodulation method thereof

A fiber grating and strain sensing technology, which is applied in the direction of transmitting sensing components, thermometers, and converting sensor output with optical devices, can solve the problems of reducing strain accuracy in low frequency bands, fiber laser noise, and affecting the accuracy of fiber laser sensors. The effect of solving the deterioration of strain accuracy and low power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

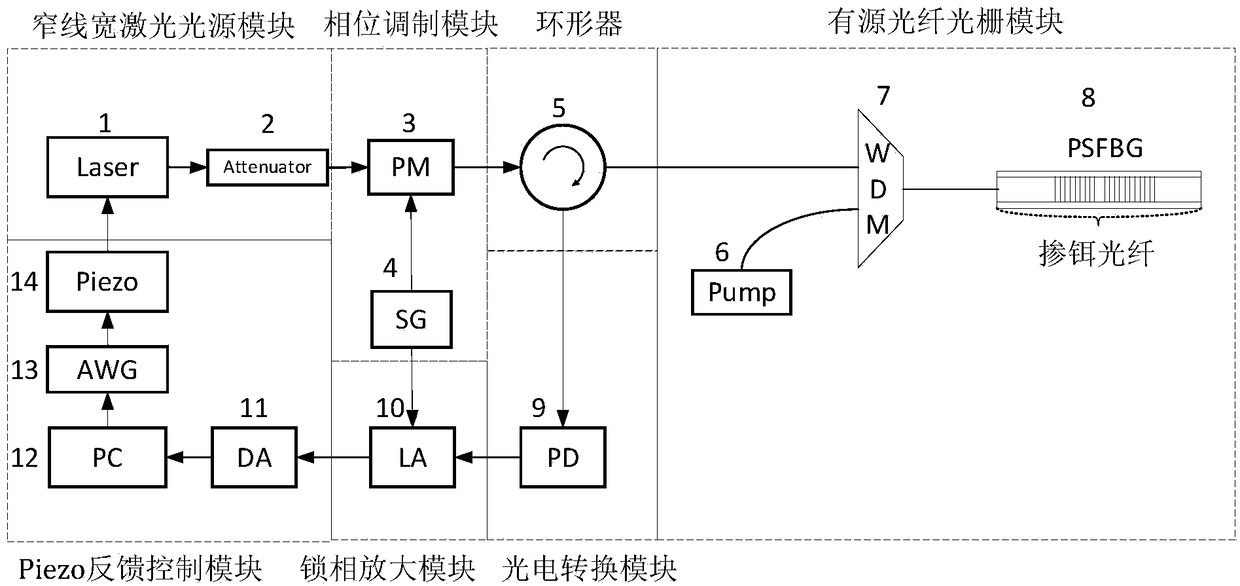

[0043] Such as figure 1 As shown, this embodiment includes: a narrow linewidth laser source module, a phase modulator module, a circulator 5, an active fiber grating module, a photoelectric conversion module, a lock-in amplifier and a feedback control module, wherein: the narrow linewidth laser source module Generate a single-frequency seed laser with a certain optical power, and the phase modulator module phase-modulates the seed light to generate carrier and sidebands, and enter the active fiber grating module from ports 1 and 2 of the circulator; the seed laser that enters the active fiber grating The frequency and phase of the laser output from the active fiber grating will be controlled, and the laser output from the active fiber grating will enter the photoelectric conversion module through the 2 and 3 ports of the circulator to realize the conversion of the optical signal and the electrical signal to obtain the beat frequency signal; the lock-in amplifier from Extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com