Paper prepared from wastes of agriculture and forestry and preparation method for paper

A technology of agricultural and forestry waste and paper, applied in the field of pulp and paper making, can solve the problems of reducing the kappa value of pulp and low pulping yield, and achieve the promotion of decomposition and chemical bond breaking, high fiber yield, and good hygienic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

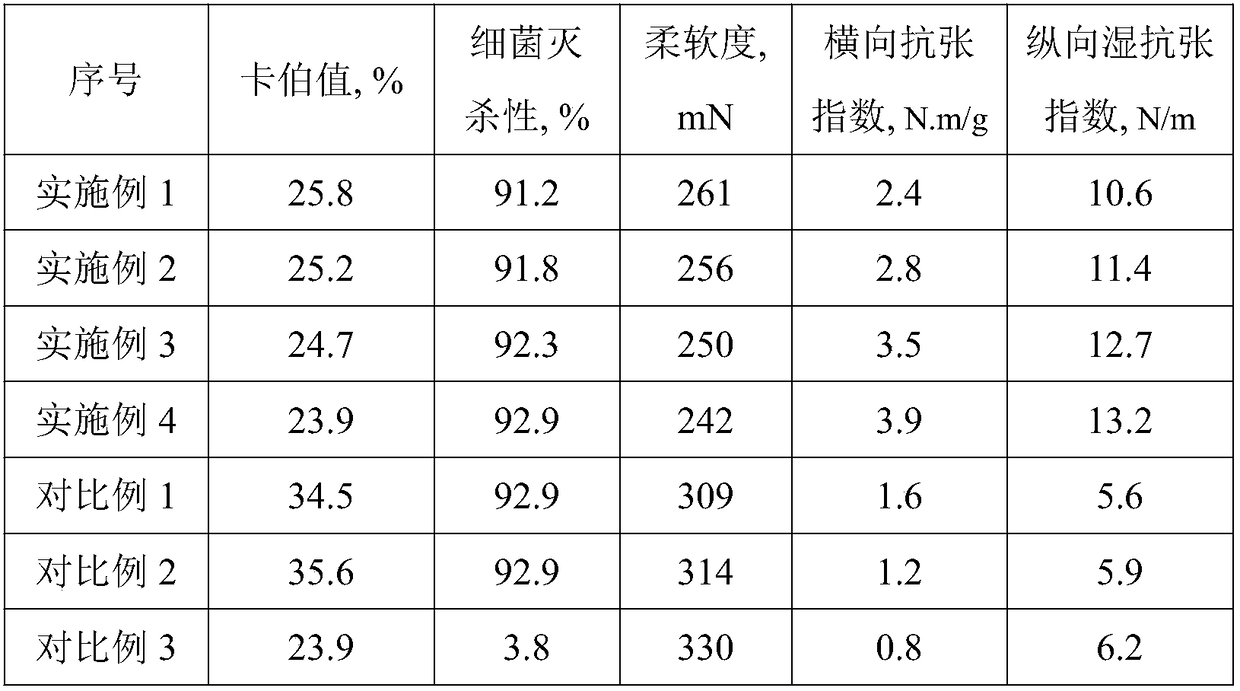

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing agricultural and forestry waste paper, and the specific operation steps are as follows:

[0031] S1. Deslagging the agricultural and forestry wastes, removing the silt and dust therein, drying until the water content is 20%, placing the above-mentioned agricultural and forestry wastes in a pre-steaming bin for steaming treatment, the steaming temperature is 70°C, The time is 30min, then carry out screw extrusion processing, the compression ratio of screw extrusion processing is 1:1, obtains coarse slurry;

[0032] S2. Repeatedly soak, disperse and wash the coarse slurry obtained in step S1 with water until the washing water is neutral, then send it to a high-consistency disc refiner for normal pressure refining, the refining concentration is 25%, and the temperature is 80°C , the time is 3 hours, the pulp after refining is put into the delatency washing, the delatency temperature is 70 ℃, and the time is 2 hours, so that t...

Embodiment 2

[0038] This embodiment provides a method for preparing agricultural and forestry waste paper, and the specific operation steps are as follows:

[0039] S1. Deslagging the agricultural and forestry wastes, removing the silt and dust therein, drying until the water content is 30%, placing the above-mentioned agricultural and forestry wastes in a pre-steaming bin for steaming treatment, the steaming temperature is 80°C, The time is 20min, then carry out screw extrusion processing, the compression ratio of screw extrusion processing is 2:1, obtains coarse slurry;

[0040] S2. Repeatedly immerse, disperse and wash the coarse slurry obtained in step S1 with water until the washing water is neutral, then send it to a high-consistency disc refiner for normal pressure refining, the refining concentration is 30%, and the temperature is 70°C , the time is 4h, the pulp after refining is put into the delatency washing, the delatency temperature is 80°C, and the time is 1h, so that the fibe...

Embodiment 3

[0046] This embodiment provides a method for preparing agricultural and forestry waste paper, and the specific operation steps are as follows:

[0047]S1. Deslagging the agricultural and forestry wastes, removing the silt and dust therein, drying until the water content is 25%, putting the above-mentioned agricultural and forestry wastes into the pre-steaming bin for steaming treatment, the steaming temperature is 72°C, The time is 24min, then carry out screw extrusion processing, the compression ratio of screw extrusion processing is 1.5:1, obtains coarse slurry;

[0048] S2. Repeatedly immerse, disperse and wash the coarse slurry obtained in step S1 with water until the washing water is neutral, then send it to a high-consistency disc refiner for normal pressure refining, the refining concentration is 26%, and the temperature is 75°C , the time is 3.5h, put the pulp after refining into the delatency washing, the delatency temperature is 72°C, and the time is 1.5h, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com