Preparation method of high temperature resistant wave-absorbing material

A wave-absorbing material and high-temperature-resistant technology, which is applied in the fields of enzyme/microbial biochemical treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve problems such as low-temperature-resistant wave-absorbing performance, achieve excellent wave-absorbing performance, and improve absorption Wave performance, compatibility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

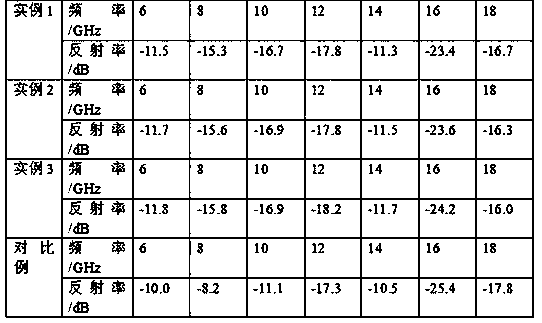

example 1

[0021] Mix deionized water, tetraethyl orthosilicate and absolute ethanol in a volume ratio of 2:5:3 and place them in a beaker and stir for 10 minutes. % hydrochloric acid, continue to mix and stir for 20 minutes to obtain a mixed solution, continue to put the mixed solution in an ultrasonic oscillator to vibrate for 35 minutes, and leave it to stand for 1 day after shaking to obtain a self-made silica sol, measure the polyimide resin and put it into a beaker Stir in the medium for 6 minutes, and heat up to 280°C to obtain a melt, then add peanut oil with a mass of 7% of the melt and yogurt with a mass of 0.7% of the melt to the melt, put it into a fermenter, and heat it at a temperature of 45°C Sealed and fermented for 9 days. After the fermentation, the fermented resin was obtained. The hexagonal boron nitride, aluminum oxide, silicon carbide and deionized water were mixed in a beaker according to the mass ratio of 1:1:1:2. In a water bath, mix and stir at a temperature of ...

example 2

[0023]Mix deionized water, tetraethyl orthosilicate and absolute ethanol in a volume ratio of 2:5:3 and place them in a beaker and stir for 11 minutes. % hydrochloric acid, continue to mix and stir for 25min to obtain a mixed solution, continue to put the mixed solution into an ultrasonic oscillator to vibrate for 40min, and leave it to stand for 1.5 days after shaking to obtain a self-made silica sol, measure the polyimide resin and put it into a beaker Stir in the medium for 7 minutes, and heat up to 290°C to obtain a melt, then add peanut oil with a mass of 7% of the melt and yogurt with a mass of 0.7% of the melt to the melt, put it into a fermenter, and heat it at a temperature of 50°C Sealed and fermented for 10 days. After the fermentation, the fermented resin was obtained. The hexagonal boron nitride, aluminum oxide, silicon carbide and deionized water were mixed in a beaker according to the mass ratio of 1:1:1:2. In a water bath, mix and stir at a temperature of 65°C ...

example 3

[0025] Mix deionized water, tetraethyl orthosilicate and absolute ethanol in a volume ratio of 2:5:3 and place them in a beaker and stir for 12 minutes. % hydrochloric acid, continue to mix and stir for 30 minutes to obtain a mixed solution, continue to put the mixed solution into an ultrasonic oscillator to vibrate for 45 minutes, and leave it to stand for 2 days after shaking to obtain a self-made silica sol, measure the polyimide resin and put it into a beaker Stir in the medium for 8 minutes, and heat up to 300°C to obtain a melt, then add peanut oil with a mass of 7% of the melt and yogurt with a mass of 0.7% of the melt to the melt, put it in a fermenter, and heat it at a temperature of 55°C Sealed and fermented for 11 days. After the fermentation, the fermented resin was obtained. The hexagonal boron nitride, aluminum oxide, silicon carbide and deionized water were mixed in a beaker according to the mass ratio of 1:1:1:2. In a water bath, mix and stir at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com