Method for preparing easily-digestible sturgeon active calcium powder by two-step fermentation and calcium powder prepared by method

An active calcium powder and easy-to-digest technology, which is applied in the field of food processing, can solve the problems of restricting the sustainable development of the sturgeon industry, low breeding profits, increasing production without increasing income, etc., to achieve low calcium utilization rate, good product quality, and save production The effect of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

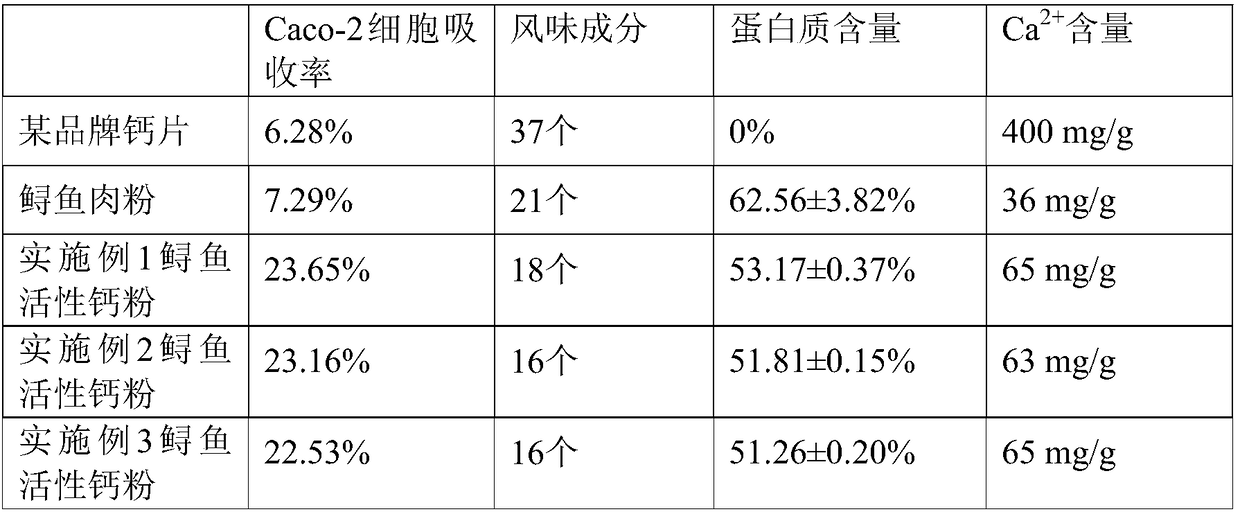

Examples

Embodiment 1

[0021] (1) After preliminarily chopping the fish skin and fish bone of the sturgeon, pass through a 200-mesh sieve through a wet method of superfine grinding;

[0022] (2) Add 1.0wt% trypsin (20000U / g) and 0.5wt% lipolytic enzyme (5000U / g) at a temperature of 10°C, stir for 60 minutes to promote proteolysis and lipolysis, and centrifuge at 5000g / min to remove impurities and purify Sturgeon paste.

[0023] (3) First fermentation: adjust the pH value of the sturgeon paste to 4.5, add the activated Lactobacillus acidophilus and Rhizopus fermentation broth at a temperature of 22°C, and ferment for 3 hours;

[0024] (4) The second variable temperature fermentation: add calcium gluconate (0.05wt%) and whey protein powder (5wt%) to the sturgeon paste, fully stir evenly, gradually heat up to 30°C during the stirring process, maintain 30min, and cool down Add Karl's yeast at 25°C and ferment for 1 hour until the concentration of bacteria in the surimi paste reaches 10 4 CFU / mL, stop ...

Embodiment 2

[0027] (1) After preliminarily chopping the fish skin and fish bone of the sturgeon, pass through a 200-mesh sieve through a wet method of superfine grinding;

[0028] (2) Add 0.8wt% trypsin (20000U / g) and 0.3wt% lipolytic enzyme (5000U / g) at 15°C, stir for 50min to promote proteolysis and lipolysis, and centrifuge at 2000g / min to remove impurities and purify the sturgeon pulp.

[0029] (3) First fermentation: adjust the pH value of the sturgeon paste to 4.7, add the activated Lactobacillus acidophilus and Rhizopus fermentation broth at 20° C., and ferment for 4 hours.

[0030] (4) The second temperature-variable fermentation: add calcium gluconate (0.10wt%) and whey protein powder (4wt%) to the sturgeon paste, stir well, gradually heat up to 34°C during the stirring process, maintain 20min, and cool down Add Karl's yeast to 25°C and ferment for another 1.25 hours.

[0031] (5) Add 2.5wt% maltodextrin to the surimi paste and then spray dry it, add 100 international units of ...

Embodiment 3

[0033] (1) After preliminarily chopping the fish skin and fish bone of the sturgeon, pass through a 200-mesh sieve through a wet method of superfine grinding;

[0034] (2) Add 1.2wt% trypsin (20000U / g) and 0.4wt% lipolytic enzyme (5000U / g) at 12°C, stir for 70min to promote proteolysis and lipolysis, and centrifuge at 3500g / min to remove impurities and purify the sturgeon pulp.

[0035] (3) First fermentation: adjust the pH value of the sturgeon paste to 5.0, add the activated Lactobacillus acidophilus and Rhizopus fermentation broth at 18° C., and ferment for 5 hours.

[0036] (4) The second variable temperature fermentation: add calcium gluconate (0.15wt%) and whey protein powder (3wt%) to the sturgeon paste, stir well, gradually heat up to 32°C during the stirring process, maintain 40min, and cool down Add Karl's yeast to 25°C and ferment for another 1.5 hours.

[0037] (5) Add 3.5wt% maltodextrin to the surimi slurry and then spray dry it. Add 100 international units of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com