Ternary compound dye and method for preparing high-color-fastness veneer layer by adopting dye

A technology with high color fastness and dyes, which is applied in the field of decorative materials, can solve problems such as affecting service life, poor tight bonding, and human damage, and achieve the effects of increasing service life, good health care, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with examples, and the present invention is not limited by the following examples.

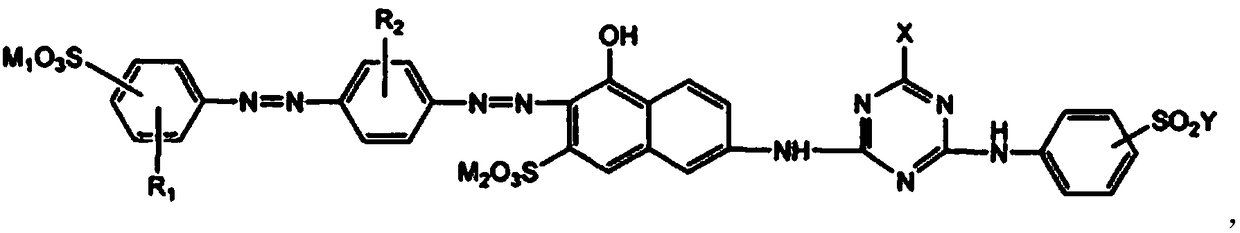

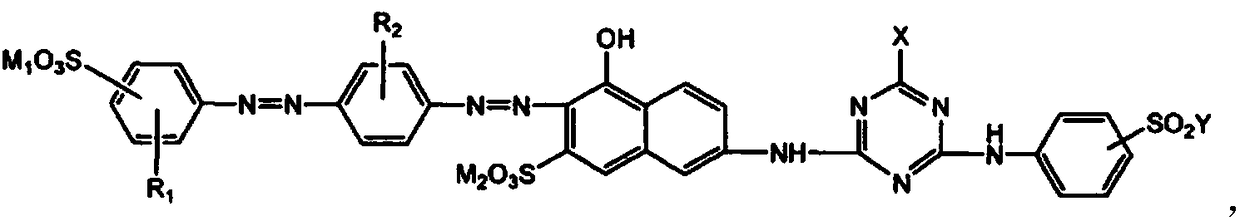

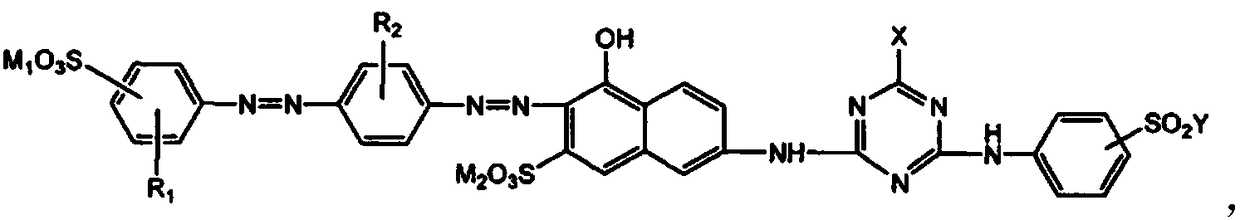

[0024] The invention discloses a ternary compound dye, which is compounded by a biomass nanofiber solubilizer, a hindered amine light stabilizer and an acidic disazo dye according to the mass ratio of 1:15-30:100-300 . The configuration of biomass nanofiber solubilizer: by weight, 1-3 parts of bamboo leaf flavonoids, 0.5-0.8 parts of β-cyclodextrin peppermint oil micropowder, and 3-6 parts of silicon dioxide and / or hydrogen Add 2-5 parts of aluminum oxide to the cellulose colloid suspension composed of 4-7 parts by weight of cellulase and 80-150 parts by weight of microcrystalline cellulose, and then add 3-chloro-hydroxypropyl triethyl chloride 0.5-1.8 parts of ammonium, prepared by stirring and reacting at 60-80°C for 18-30 minutes. The preparation method of β-cyclodextrin peppermint oil micropowder is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com