Preparation method of large-diameter graphene and large-diameter graphene

A graphene and large-scale technology, applied in the preparation of large-diameter graphene, large-diameter graphene, and graphene materials, can solve the problem of strong adsorption force between macromolecules and graphene, difficult to obtain large-diameter graphene, and difficult to achieve large-scale Preparation and other problems, to achieve the effect of easy recovery and reuse, easy to achieve industrial scale production, easy to industrialize large-scale popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A preparation method for large sheet diameter graphene, comprising the following steps:

[0076] (a) Prepare high-viscosity syrup: mix water, sucrose, glucose and fructose according to the ratio of water:sucrose:glucose:fructose=6:12:6:15 at room temperature 18-19°C, and use a Brookfield viscometer to test Its viscosity is 112000 centipoise;

[0077] (b) Mechanical exfoliation: 20g of the above-mentioned high-viscosity syrup is mixed with 0.5g and 100 mesh graphite powder, and the mixed material is transferred to a three-roll grinder, and the roll mill is 3h to obtain a mixture of graphene and syrup;

[0078] (c) Separation: add hot water at 70°C to the mixture of graphene and syrup obtained in step (b) to dissolve, centrifuge at 7000rpm for 10min, collect the supernatant of the first centrifugation, and then repeatedly wash and centrifuge the lower solid for 4 times to obtain large pieces diameter graphene;

[0079] (d) Recovery of syrup: The supernatant collected in...

Embodiment 2

[0083] A preparation method for large sheet diameter graphene, comprising the following steps:

[0084] (a) Prepare high-viscosity syrup: mix water, sucrose and fructose in the ratio of water: sucrose: fructose = 2:5:3 at a room temperature of 18-20°C, and measure its viscosity with a Brookfield viscometer to 245,000 centipoise ;

[0085] (b) Mechanical exfoliation: get 80g of the above-mentioned high-viscosity syrup and add 0.8g, 80-purpose expanded graphite, under an ice-water bath, adopt a high-speed disperser to carry out mechanical stirring for 3h to obtain a mixture of graphene and syrup;

[0086](c) Separation: add hot water at 70°C to the mixture of graphene and syrup obtained in step (b) to dissolve, centrifuge at 7000rpm for 10min, collect the supernatant of the first centrifugation, and then repeatedly wash and centrifuge the lower solid for 4 times to obtain large pieces diameter graphene;

[0087] (d) Recovery of syrup: The supernatant collected in step (c) is s...

Embodiment 3

[0090] A kind of preparation method of large diameter graphene, and the difference of embodiment 2 is:

[0091] (b) mechanical exfoliation: get 100g high-viscosity syrup and add 2g, 80 purpose expanded graphite, under ice-water bath, adopt high-speed disperser to carry out mechanical stirring for 5h, obtain the mixture of graphene and syrup;

[0092] All the other are with embodiment 2.

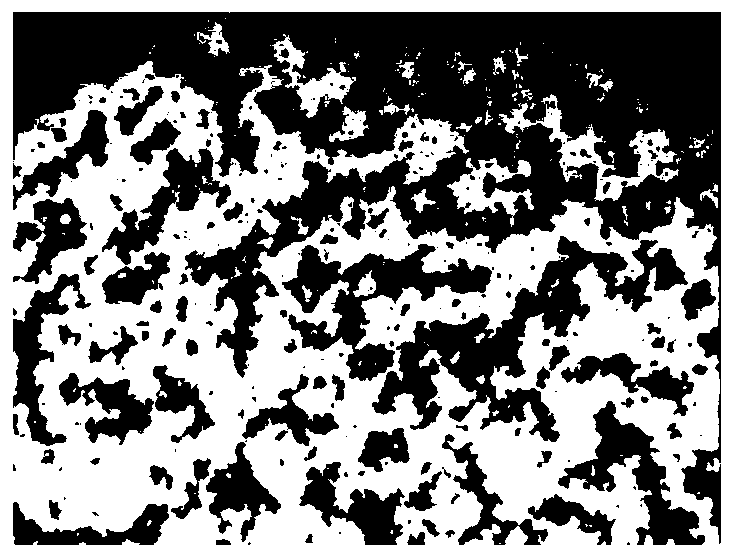

[0093] Take a small amount of centrifuged lower layer solid, add 25mL DMF to sonicate for 20min, make slices on glass slides, and observe the effect under a microscope. Figure 4 , the actual length and width dimensions corresponding to the picture are 141 μm×106 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com