High-dielectric polyphenyl ether material as well as preparation method and application thereof

A technology of polyphenylene ether and polystyrene, which is applied in the field of high dielectric polyphenylene ether materials and its preparation, can solve the problems of low dielectric loss and inability to increase the dielectric constant, and achieve low dielectric loss and high dielectric Constant and low dielectric loss electrical properties, effect of small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

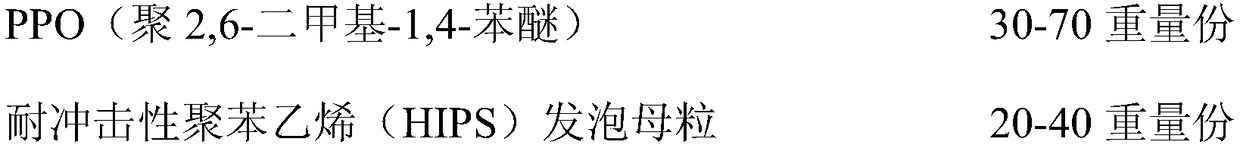

[0061] In this embodiment, the raw materials for the preparation of polyphenylene ether materials include the following components in parts by weight:

[0062]

[0063] Wherein the preparation raw material of impact-resistant polystyrene foam masterbatch comprises the following components by weight:

[0064]

[0065] The high dielectric filler is a compound of barium strontium titanate, calcium copper titanate and titanium carbide, the compounding ratio is 80:10:10, and the antioxidant is antioxidant 1076 and antioxidant PL- Mixture of 10.

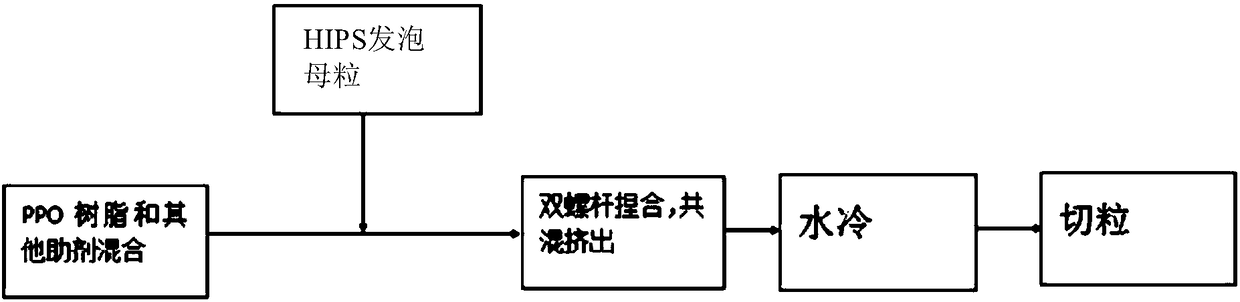

[0066] The preparation method of the polyphenylene ether material comprises the following steps:

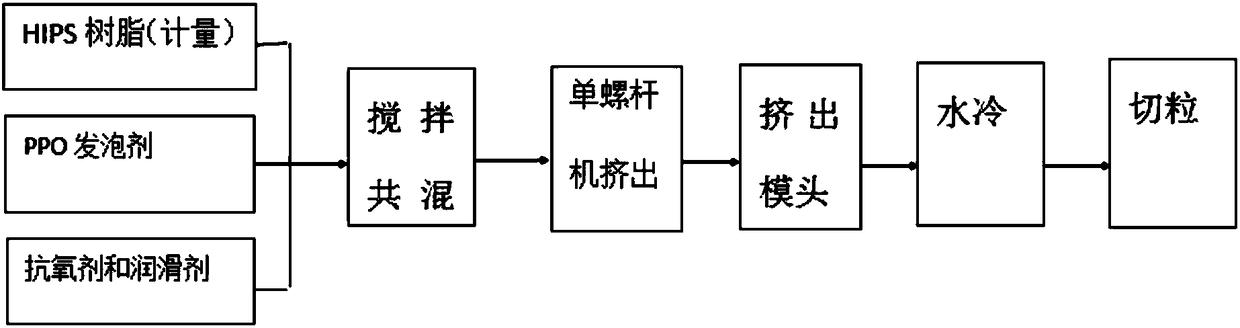

[0067] (1) Mix the impact-resistant polystyrene, PPO foaming agent, antioxidant and lubricant evenly, and then use a single-screw extruder to extrude, water-cool, and pelletize to obtain the impact-resistant polystyrene masterbatch , the process flow is as figure 1 As shown; the feeding speed of the single-screw extruder is 50r / min, ...

Embodiment 2

[0070] In this embodiment, the raw materials for the preparation of polyphenylene ether materials include the following components in parts by weight:

[0071]

[0072] The high dielectric filler is a compound of barium strontium titanate, calcium copper titanate and titanium carbide, the compounding ratio is 80:10:10, and the antioxidant is antioxidant 1076 and antioxidant PL- Mixture of 10.

[0073] Wherein the preparation raw material of impact-resistant polystyrene foam masterbatch comprises the following components by weight:

[0074]

[0075] The preparation method of the polyphenylene ether material comprises the following steps:

[0076] (1) Mix the impact-resistant polystyrene, PPO foaming agent, antioxidant and lubricant evenly, and then use a single-screw extruder to extrude, water-cool, and pelletize to obtain the impact-resistant polystyrene masterbatch , the process flow is as figure 1 As shown; the feeding speed of the single-screw extruder is 50r / min, ...

Embodiment 3

[0079] In this embodiment, the raw materials for the preparation of polyphenylene ether materials include the following components in parts by weight:

[0080]

[0081]

[0082] The high dielectric filler is a compound of barium strontium titanate, calcium copper titanate and titanium carbide, the compounding ratio is 80:10:10, and the antioxidant is antioxidant 1076 and antioxidant PL- Mixture of 10.

[0083] Wherein the preparation raw material of impact-resistant polystyrene foam masterbatch comprises the following components by weight:

[0084]

[0085] The preparation method of the polyphenylene ether material comprises the following steps:

[0086] (1) Mix the impact-resistant polystyrene, PPO foaming agent, antioxidant and lubricant evenly, and then use a single-screw extruder to extrude, water-cool, and pelletize to obtain the impact-resistant polystyrene masterbatch , the process flow is as figure 1 As shown; the feeding speed of the single-screw extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com