Advanced oxidation coupling biological cleaning system based on ozone regulation and application thereof

A biological purification and advanced oxidation technology, applied in the field of environmental pollution purification, can solve the problems of not realizing the important role of ozone, not paying attention to the effect of ozone, etc., and achieve the effect of thorough purification and high biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

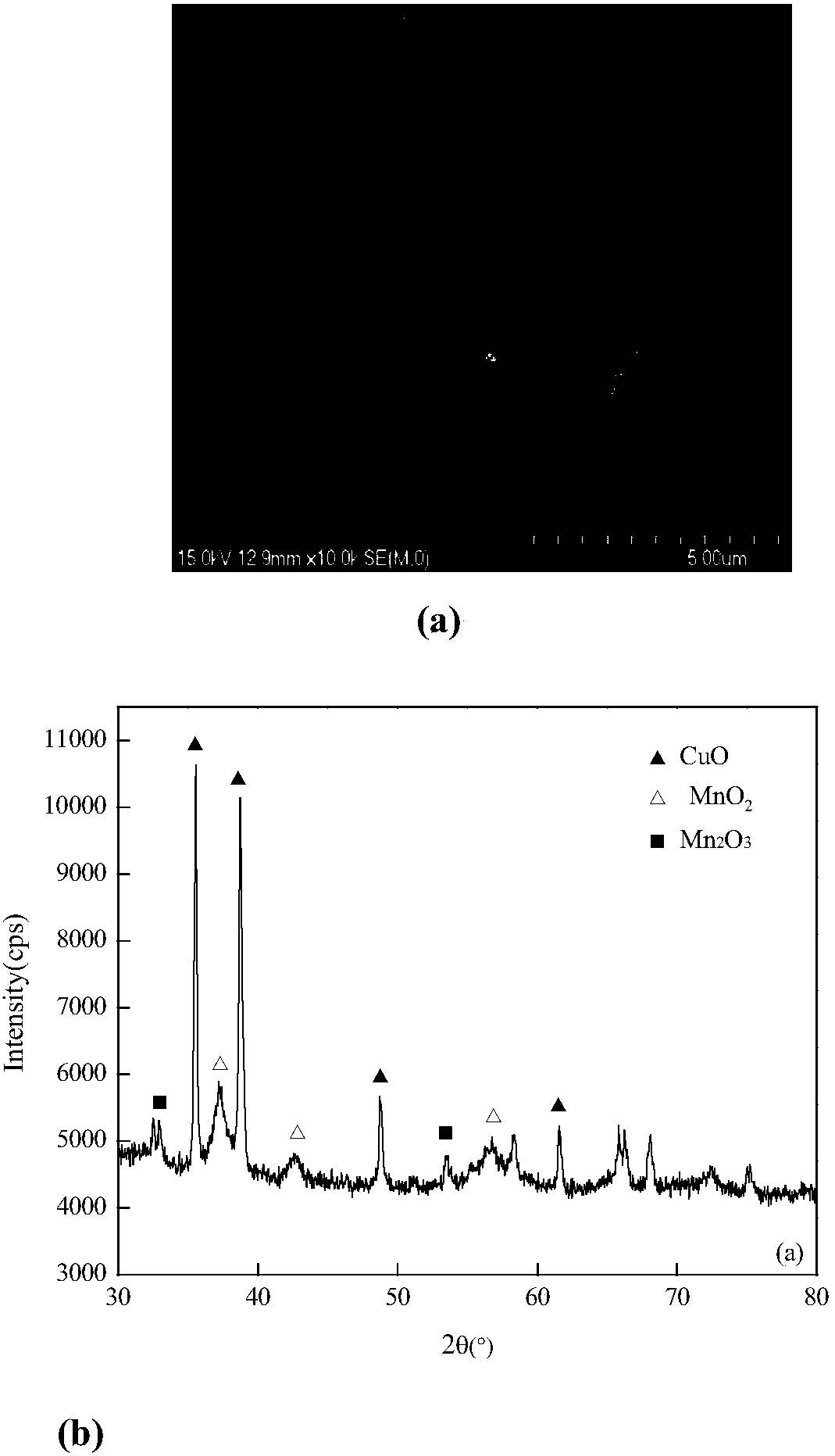

[0040] Embodiment 1: preparation of copper-manganese composite catalyst

[0041] Mass loading 20% CuO / MnO 2 Composite catalyst: take MnCO 3 Placed in a muffle furnace and calcined at 400°C for 6 hours to obtain MnO 2 spare. Take 0.2g of Cu(NO 3 ) 2 ·3H 2 O, dissolved in 6mL of deionized water, weighed 1gMnO 2 Add while stirring, dry at 80°C for 12h, calcinate at 400°C for 3h, and take it out after cooling to obtain CuO / MnO with a mass fraction of 20%. 2 Composite catalyst 1.10g.

[0042] For 20% CuO / MnO 2 The composite catalysts were structurally characterized. XRD analysis shows that the existence form of copper in the sample is CuO monoclinic system, and its diffraction peak is sharp, indicating that its crystallinity is good, the crystal phase content is high and the grain is large, and the existence form of manganese is β-MnO 2 and Mn 2 o 3 mixed phase. BET analysis showed that the specific surface area and pore volume of the catalyst were 34.96m 2 / g and 0.1...

Embodiment 2

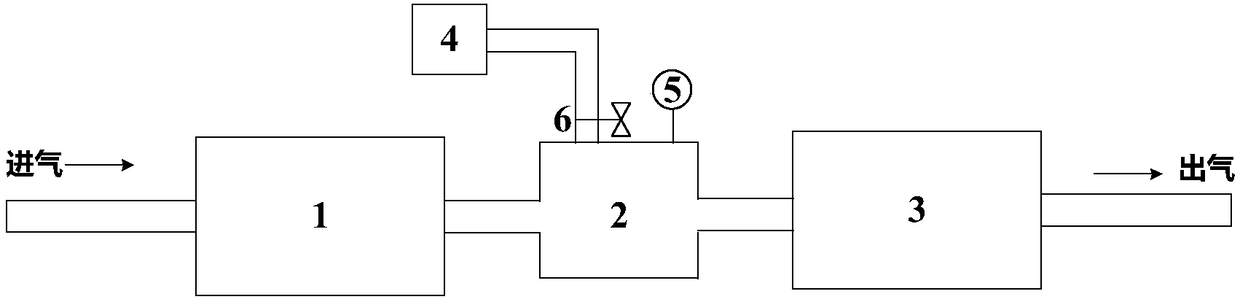

[0044] Example 2: O in low temperature plasma synergistic catalytic process 3 Production

[0045] refer to figure 2 Middle b, the low-temperature plasma synergistic catalytic device is a tube body (diameter 8cm, length 40cm), with a first exhaust gas inlet 7 and a first exhaust gas outlet 11, from the first exhaust gas inlet 7 to the first exhaust gas outlet 11 along the axial direction A gas buffer zone 8, a plasma discharge area 9 and a catalyst placement area 10 are set; in the plasma discharge area, a quartz tube is used as a discharge medium, a stainless steel iron rod is used as an inner electrode, and a dielectric barrier discharge is adopted; the catalyst placement area is set along 2 pieces of stainless steel mesh coated with catalyst placed vertically in the axial direction, the stainless steel mesh next to the plasma discharge area is 2cm away from the discharge area, and the rest of the stainless steel mesh is separated by 1cm.

[0046] 40% CuO / MnO by mass fract...

Embodiment 3

[0051] Embodiment 3: O in the ultraviolet photocatalysis process 3 Production

[0052] refer to figure 2 In a, the ultraviolet photocatalytic device is a cylinder with a sealing cover, and the sealing cover is provided with a second waste gas inlet 1, a second waste outlet 2 and an ultraviolet lamp installation port 3, and the ultraviolet lamp installation port is There is a sleeve 4 sealingly connected with the sealing cover. The sleeve extends into the cylinder and is used to place the ultraviolet lamp tube 5. A catalyst-coated quartz boat 6 is arranged between the outer wall of the sleeve and the inner wall of the cylinder.

[0053] With 60% CuO / MnO 2 As a catalyst, coated on a total area of 20cm 2 On a quartz boat, the coating weight is 0.05g / cm 2 , and placed under the ultraviolet lamp, the main wavelength of the ultraviolet lamp is 185nm, the power is 36w, and two lamps are set. Firstly, under the condition of same light source input before and after catalyst coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com