Catalyst, preparation method of catalyst and application of catalyst for catalyzing regeneration of effective anthraquinone from anthraquinone degradation product

A catalyst and oxide technology, applied in the chemical industry, can solve the problems of poor regeneration effect, difficulty in meeting the production needs of hydrogen peroxide, and low total conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

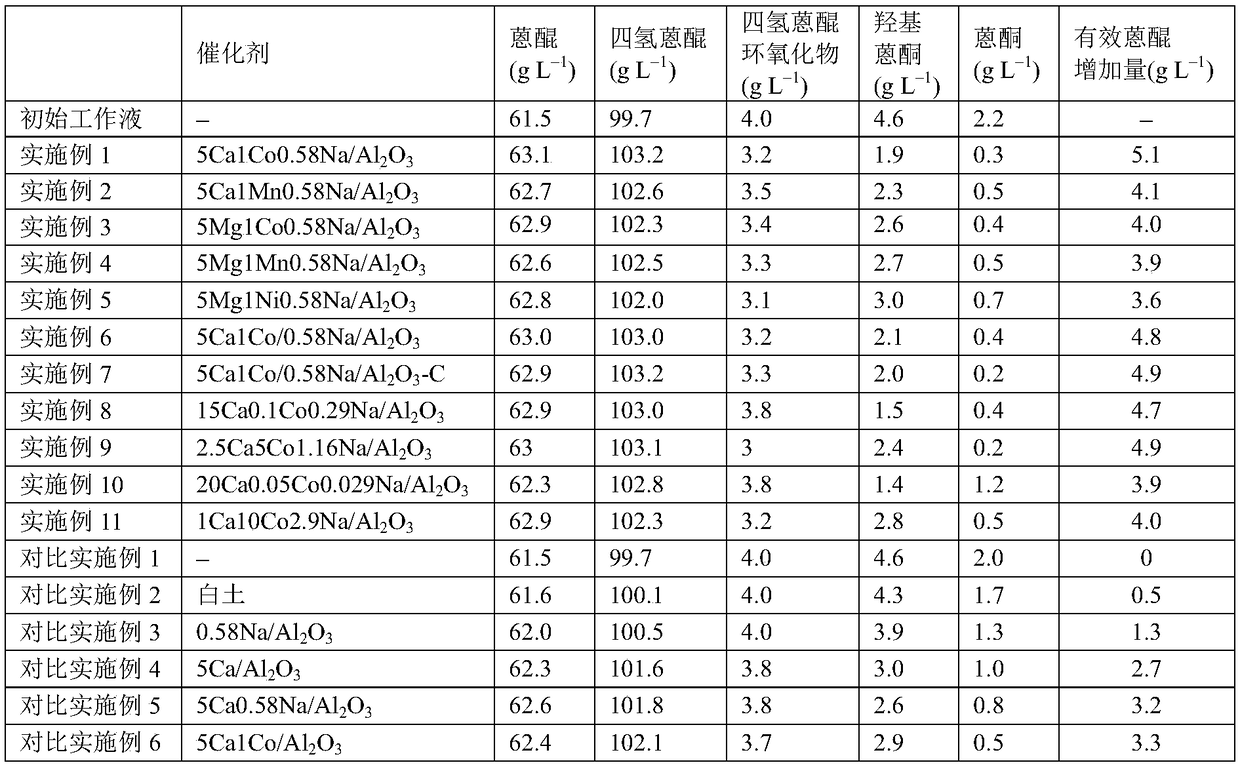

Examples

preparation example Construction

[0021] On the other hand, the present disclosure also provides a method for preparing a catalyst, the method comprising: loading an active component precursor on a carrier to obtain a loaded carrier, and then calcining the loaded carrier; The active component precursor contains a compound containing an alkali metal element, a compound containing an alkaline earth metal element, and a compound containing a transition metal element of the fourth period; the loading of the active component precursor makes the catalyst prepared by The amount of the carrier is based on the oxide, the content of the alkali metal element is 0.00001-30% by weight, the content of the alkaline earth metal element is 0.0001-60% by weight, and the content of the transition metal element of the fourth period is The content is 0.00001-30% by weight.

[0022] Wherein, optionally, the loading amount of the active component precursor is such that in the prepared catalyst, based on the amount of the carrier, th...

Embodiment 1

[0044] Weigh 2.4g of sodium nitrate, 31.6g of calcium nitrate tetrahydrate and 5.8g of cobalt nitrate hexahydrate to prepare 130mL impregnating solution, add the above impregnating solution dropwise to 150.0g activated alumina under stirring, and impregnate at 35°C 8h, then rotary evaporated at 60°C to remove a little excess water, the obtained solid was dried at 110°C for 6h, then raised to 550°C at 10°C / min in air atmosphere and kept for 4h, the final catalyst was obtained, expressed 5Ca1Co0.58Na / Al 2 o 3 . Weigh 20g of catalyst and fill it into a stainless steel fixed bed with an inner diameter of 10mm. The working fluid is boosted and metered by a metering pump and flows through the catalyst bed from the bottom of the reactor with a space velocity of 1.8h -1 , the reaction temperature was 60°C, and samples were taken for analysis after 6 hours of reaction. Quantitative analysis of each component was carried out by gas chromatography, and the results are listed in Table ...

Embodiment 2

[0046] Weigh 2.4g of sodium nitrate, 31.6g of calcium nitrate tetrahydrate and 6.2g of 50% manganese nitrate solution, and prepare 130mL impregnating solution, and add the above impregnating solution dropwise to 150.0g activated alumina under stirring, at 30°C Immerse under low temperature for 8h, then remove slightly excess water by rotary evaporation at 60°C, dry the obtained solid at 110°C for 6h, then raise it to 550°C at 10°C / min in air atmosphere and keep it for 4h to obtain the final catalyst , expressed as 5Ca1Mn0.58Na / Al 2 o 3 . Catalyst evaluation is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com