Preparation of carbon-coated nano hollow bismuth monomer and application of carbon-coated nano hollow bismuth monomer to alkaline battery

An alkaline battery, carbon coating technology, applied in the direction of alkaline storage battery, battery electrode, nanotechnology, etc., can solve the problems of poor chemical structure stability, metal bismuth simple substance is easy to be corroded and oxidized, etc., to achieve stable product structure and properties, Excellent rate performance and cycle durability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

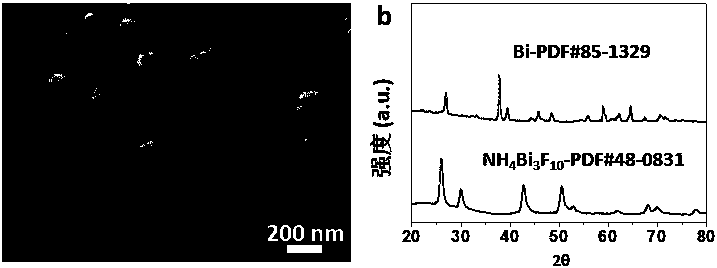

[0027] Example 1 Synthesis of carbon-coated metal nano-hollow bismuth negative electrode material

[0028] (1) Bismuth ammonium fluoride (NH 4 Bi 3 f 10 ) precursor synthesis: take 0.2 g Bi(NO 3 ) 3 ·6H 2 O and 0.6 g of NH 4 F were placed in 25 mL ethylene glycol centrifuge tubes for vortex dissolution. The above two solutions were mixed evenly, and after standing at room temperature for 12 hours, after filtering and washing, at 60 o Dry the sample at C for 8 hours to obtain NH 4 Bi 3 f 10 precursor material.

[0029] (2) Synthesis of carbon-coated metal nano-hollow bismuth anode material: take 0.4 g NH 4 Bi 3 f 10 Added to the solution containing 0.1 g dopamine molecules, stirred at room temperature for 6 hours, centrifuged and washed with absolute ethanol several times, and then at 60 o C dried the sample for 8 hours to obtain gray NH 4 Bi 3 f 10 @PDA nanopowder. Next, in an argon atmosphere at 400 o C low-temperature carbonization for 30 minutes to obtain...

Embodiment 2

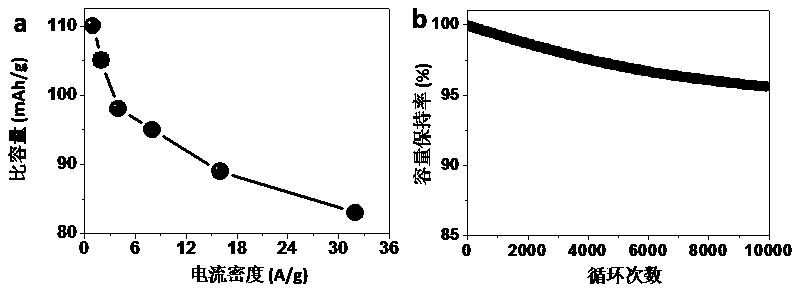

[0031] Example 2 Production and Test Method of Alkaline Full Battery Using Carbon-coated Metal Nano Hollow Bismuth as Negative Electrode

[0032] (1) Negative electrode sheet production: After mixing the negative electrode material, conductive agent and binder in a mass ratio of 8:1:1, add an appropriate amount of N-methylpyrrolidone solvent and stir for 12 hours to obtain a black viscous slurry material. Spread the slurry evenly on the foamed nickel collector electrode with a scraper, 120o C vacuum dried for 12 hours to obtain the negative electrode sheet.

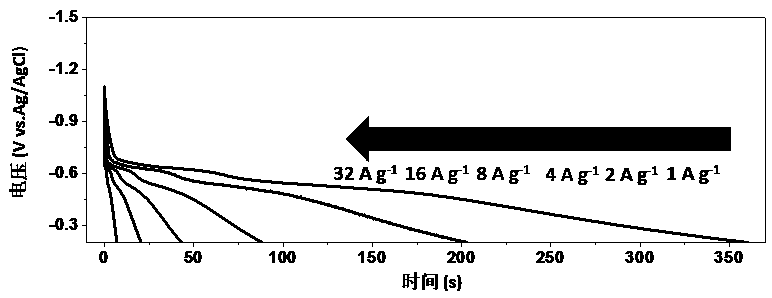

[0033] (2) Electrode sheet activation and testing: The electrode sheet prepared in step (2) was used as the working electrode, Ag / AgCl and platinum wire were used as the reference electrode and counter electrode, and 6 mol / L sodium hydroxide solution was used as the electrolytic electrode. The electrode prepared in step (2) was scanned cyclically for 100-200 circles on the electrochemical workstation at a scan rate of 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com