Oil control composition

A composition and extract technology, applied in the field of oil control compositions, can solve problems such as large side effects of drugs, and achieve the effects of controlling oil secretion, preventing inflammation, and inhibiting excessive oil secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

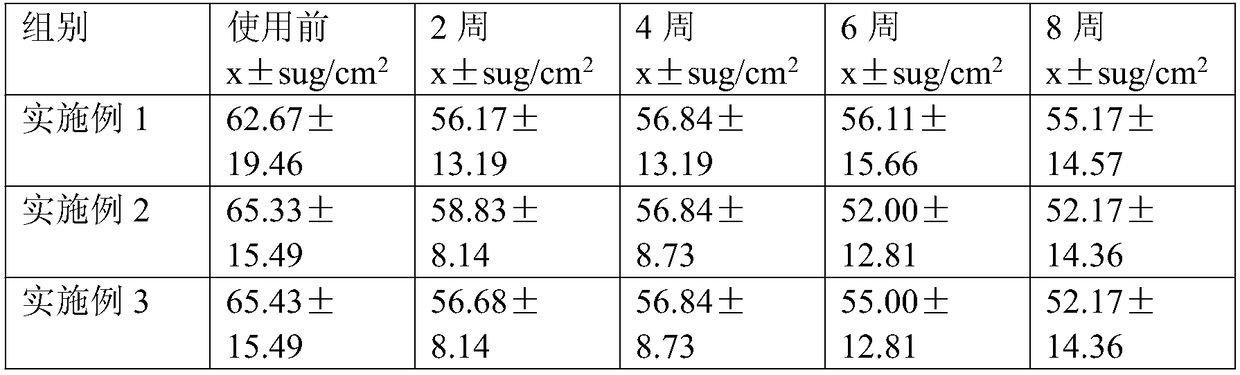

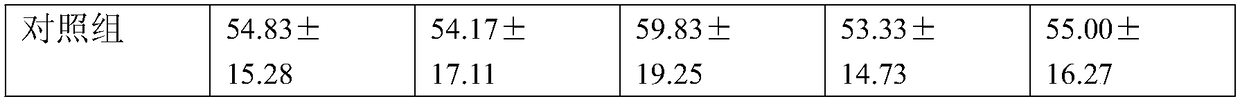

Examples

Embodiment 1

[0028] Preparation of oil control composition:

[0029] Put 12.6 grams of hydrolyzed collagen, 20 grams of propylene glycol, 4.8 grams of reed rhizome polysaccharide, 4.3 grams of pine extract, and 58.3 grams of deionized water in a mixer, and stir and mix evenly to obtain the oil control composition.

Embodiment 2

[0031] Preparation of oil control mask:

[0032] According to mass percentage, 12.5% butanediol, 8% glycerin, 0.07% sodium hyaluronate, 0.2% carbomer, 0.35% dipotassium glycyrrhizinate, 0.07% methylparaben, 55.76% deionized water were added and stirred Heat to 85°C while stirring in the pot, stir and dissolve completely, and obtain the water phase; mix 4.5% polyethylene glycol-10, 0.3% PEG-60 hydrogenated castor oil, 3% polyquaternium-51, 1.5% poly Add ethylene glycol-8, 1.5% polypropylene glycol-7, and 2% polyethylene glycol-32 into the stirring pot and heat to 85°C while stirring to obtain the oil phase; under stirring, add the oil phase to the water phase and stir evenly Cool down to 45°C, add 0.2% triethanolamine, stir evenly, add 10% oil control composition, 0.05% phenoxyethanol, stir well, then cool and discharge.

Embodiment 3

[0034] Preparation of Oil Control Facial Cleanser:

[0035] According to mass percentage, 3% squalane, 2% cetearyl alcohol, 4% polydimethylsiloxane, 2% sodium laurate sulfate, 4% alkyl sulfate, 2% myristic acid, 2.5 Put %PEG-20 methylglucose sesquistearate, 0.01% methylparaben and 0.01% propylparaben into the oil phase pot, heat to 70°C, wait for all components to dissolve and keep warm to obtain oil Phase; put 12.5% glycerin, 2% stearic acid, 0.3% carbomer, 0.04% xanthan gum and 50.44% deionized water into the water phase pot successively, heat to 70°C, keep it warm for 15min to make it fully dissolve, and prepare Obtain the oil phase; pump the water phase and the oil phase into the emulsification pot in turn, homogenize for 5 minutes, the stirring rate is 2000r / min, then keep stirring for 15 minutes, the stirring rate is 30r / min; cool to 40°C, add 0.2% hydrogen Potassium oxide, stir evenly; add 15% oil control composition and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com