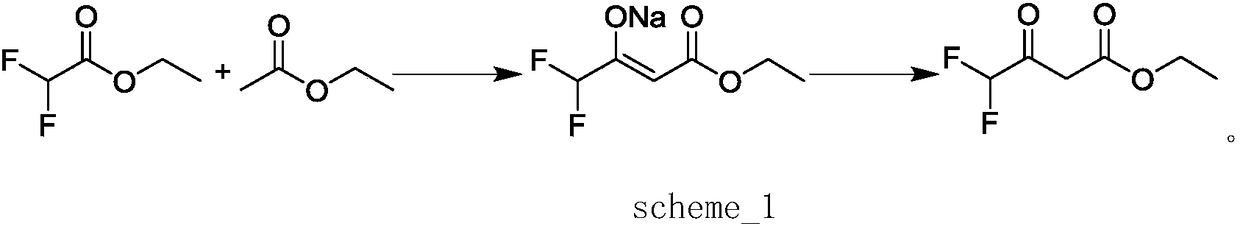

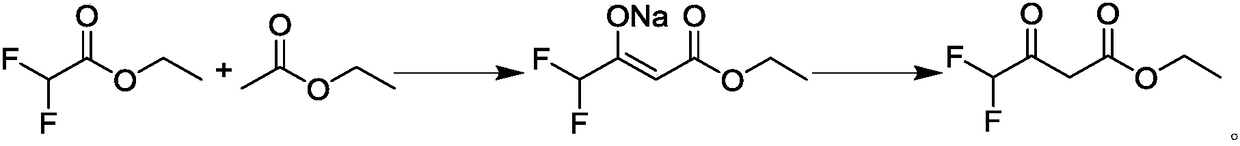

Method for preparing ethyl 4,4-difluoroacetoacetate

A technology of ethyl difluoroacetoacetate and ethyl difluoroacetate is applied in the field of preparation of ethyl 4,4-difluoroacetoacetate, and can solve the problems of low safety factor, large amount of three wastes, large waste water, etc. The effect of high selectivity, improved selectivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 200mL of absolute ethanol to the reactor at 25°C, then add 510g (1.5mol) of 20% sodium ethoxide ethanol solution, and cool the reaction solution to 5-10°C. Then start to drop a mixture of 105.6g (1.2mol) ethyl acetate and 124g (1.0mol) ethyl difluoroacetate, and control the temperature at 10-20°C. After the addition, the temperature was raised to 60°C to react for 2 hours, and then the reaction solution was cooled to 10-15°C. Add 166.6 g (1.7 mol) of concentrated sulfuric acid dropwise to the reaction solution, control the temperature at 20-30° C., and react at 30° C. for 2.5 hours after dropping, to obtain a turbid solution containing sodium sulfate precipitate.

[0051] The sodium sulfate precipitate was removed by filtration, and the filter cake was washed with ethyl acetate, and the obtained filtrate was subjected to rectification under reduced pressure to obtain 149.7g ethyl difluoroacetoacetate, and the yield was 90.2% (in terms of ethyl difluoroacetate), The...

Embodiment 2

[0053] At 25°C, 100 mL of cyclohexane was added to the reactor, and then 374 g (0.55 mol) of 10% sodium ethoxide ethanol solution was added, and the reaction solution was cooled to 5-10°C. Then start to drop a mixture of 57.2g (0.65mol) ethyl acetate and 62g (0.5mol) ethyl difluoroacetate, and control the temperature at 15-20°C. After the addition, the temperature was raised to 50°C to react for 3 hours, and then the reaction solution was cooled to 10-15°C. Add 59.2g (0.6mol) 37% concentrated hydrochloric acid dropwise to the reaction solution, control the temperature at 20-30°C, and react at 40°C for 1.5 hours after the dropwise completion to obtain a turbid solution containing sodium chloride precipitate.

[0054] The sodium chloride precipitate was removed by filtration, the filter cake was washed with ethyl acetate, and the obtained filtrate was subjected to rectification under reduced pressure to obtain 75.2 g of ethyl difluoroacetoacetate, with a yield of 90.6% (in terms...

Embodiment 3

[0056] At 25°C, 100 mL of tetrahydrofuran will be added to the reactor, and then 385.3 g (0.85 mol) of 15% sodium ethoxide ethanol solution will be added, and the reaction liquid will be cooled to 5-10°C. Then start to drop a mixture of 70.4g (0.8mol) ethyl acetate and 86.8g (0.7mol) ethyl difluoroacetate, and control the temperature at 10-20°C. After the addition, the temperature was raised to 40°C to react for 4 hours, and then the reaction solution was cooled to 10-15°C. Add 54 g (0.9 mol) of acetic acid dropwise to the reaction solution, control the temperature at 20-30° C., and react at 35° C. for 2.0 hours after the drop is completed, to obtain a turbid solution containing sodium acetate precipitate.

[0057] The sodium acetate precipitate was removed by filtration, and the filter cake was washed with ethyl acetate, and the obtained filtrate was rectified under reduced pressure to obtain 106.1 g of ethyl difluoroacetoacetate, with a yield of 91.3% (in terms of ethyl difl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com