A long cycle life lithium-sulfur battery cathode material, cathode and its preparation and application

A technology for lithium-sulfur batteries and positive electrode materials, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problem that the cycle performance is not well improved, and achieve a short preparation period, long cycle life, and prevention of dissolution. and diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

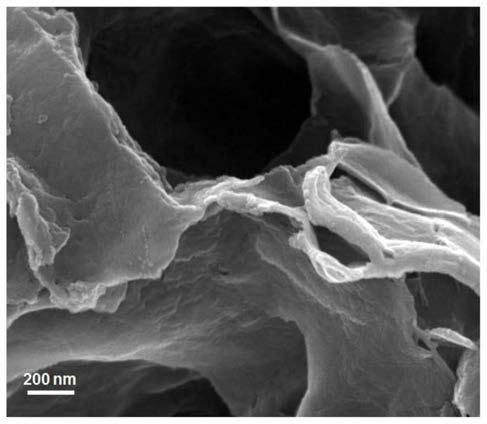

[0050] A lithium-sulfur battery positive electrode material with high cycle characteristics and a preparation method for the lithium-sulfur battery positive electrode, comprising the following steps:

[0051] (1) 6 g of thiourea was dissolved in 150 mL of distilled water with magnetic stirring, and heated in a water bath at 50° C. to obtain a thiourea solution;

[0052] (2) Under the condition of stirring (260rpm), slowly add 8 mL of formaldehyde solution with a mass fraction of 38% to the thiourea solution in step (1), after the dropwise addition, add 1 mL of hydrochloric acid with a mass fraction of 37% solution, stirred and reacted for 4 hours, suction filtered, and vacuum-dried at 60°C for 12 hours to obtain thiourea-formaldehyde resin;

[0053] (3) Mix 2g of thiourea formaldehyde resin and 6g of ordinary sulfur powder evenly, heat to 150°C, stir at 260rpm for 2 hours (melting of sulfur powder), continue to heat up to 180°C, keep warm for 8 hours, cool, grind and dry , to...

Embodiment 2

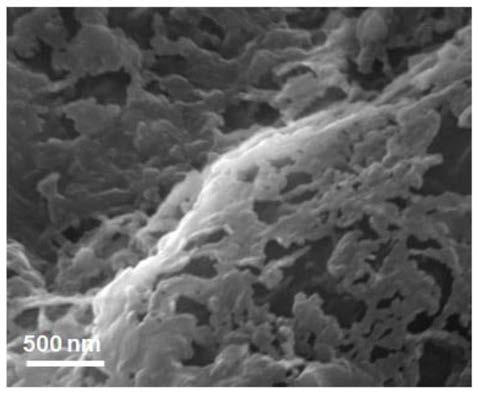

[0060] A lithium-sulfur battery positive electrode material with high cycle characteristics and a preparation method for the lithium-sulfur battery positive electrode, comprising the following steps:

[0061] (1) 5 g of thiourea was dissolved in 120 mL of distilled water with magnetic stirring, and heated in a water bath at 60° C. to obtain a thiourea solution;

[0062] (2) Under the condition of stirring (280rpm), 7 mL of formaldehyde solution with a mass fraction of 38% was slowly added dropwise to the thiourea solution in step (1). After the addition, 0.8 mL of formaldehyde with a mass fraction of 37% hydrochloric acid solution, stirred and reacted for 4 hours, suction filtered, and vacuum-dried at 60°C for 10 hours to obtain thiourea-formaldehyde resin;

[0063] (3) Mix 1g of thiourea formaldehyde resin with 5g of ordinary sulfur powder evenly, heat to 150°C, stir at 260rpm for 1 hour (melting of sulfur powder), continue to heat up to 180°C, keep warm for 8 hours, cool, gr...

Embodiment 3

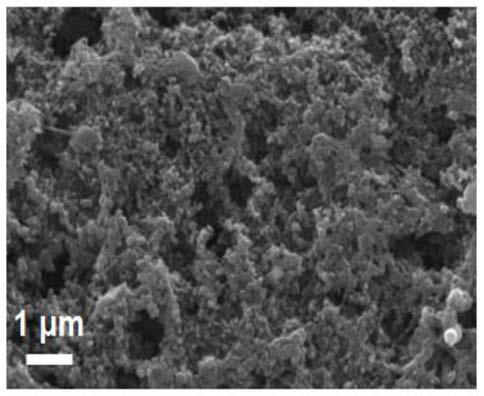

[0068] A lithium-sulfur battery positive electrode material with high cycle characteristics and a preparation method for the lithium-sulfur battery positive electrode, comprising the following steps:

[0069] (1) 6g of thiourea was dissolved in 150mL of distilled water and 1.5mL of hydrochloric acid solution with a mass fraction of 37% by magnetic stirring, and heated in a water bath at 50°C to obtain a thiourea solution;

[0070] (2) Under the condition of stirring (260rpm), 8mL of formaldehyde solution with a mass fraction of 38% was slowly added dropwise to the thiourea solution in step (1). After the dropwise addition, stirred and reacted for 4 hours, suction filtered, and ℃ vacuum drying for 18 hours to obtain thiourea-formaldehyde resin;

[0071] (3) Mix 2g of thiourea formaldehyde resin and 5g of ordinary sulfur powder evenly, heat to 150°C, stir at 280rpm for 1 hour (melting of sulfur powder), continue to heat up to 170°C, keep warm for 10 hours, cool, grind and dry ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com