Water-based polyurethane self-repairing coating material based on double-selenium dynamic covalent bond and hydrogen bond

A technology of water-based polyurethane and dynamic covalent bond, which is applied in the preparation of self-healing polyurethane water-based coating materials and the field of preparation of water-based polyurethane self-healing coating materials. It can solve the problems of no relevant reports and achieve good self-healing effect and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

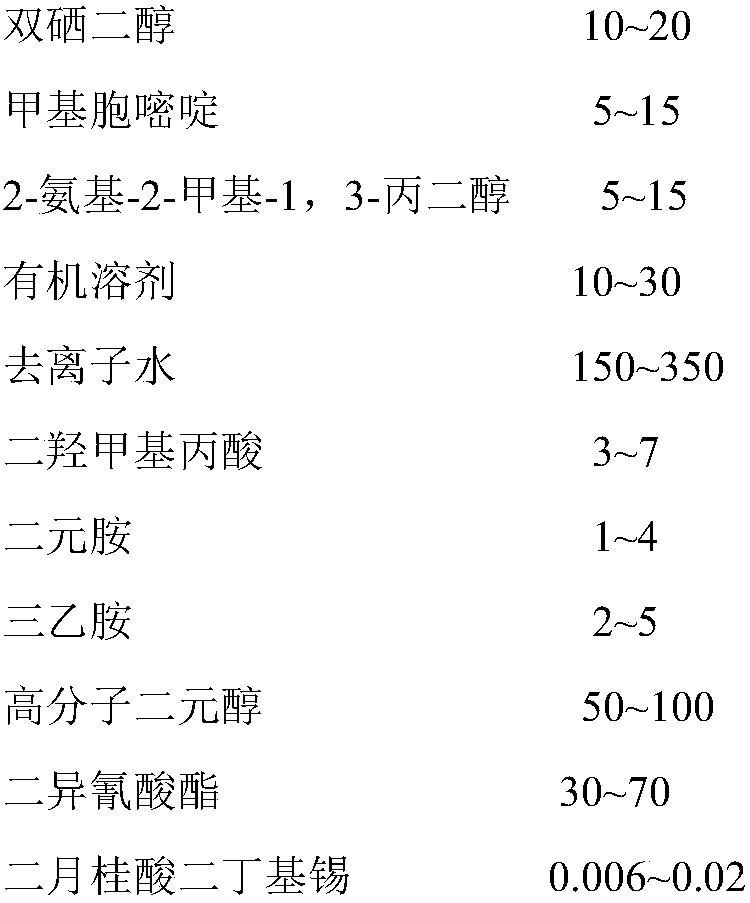

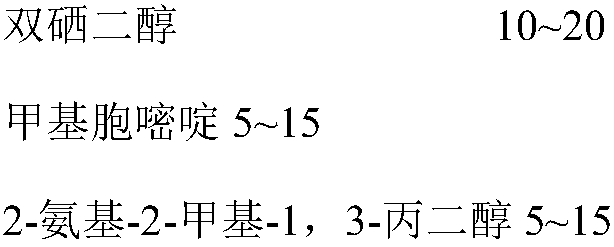

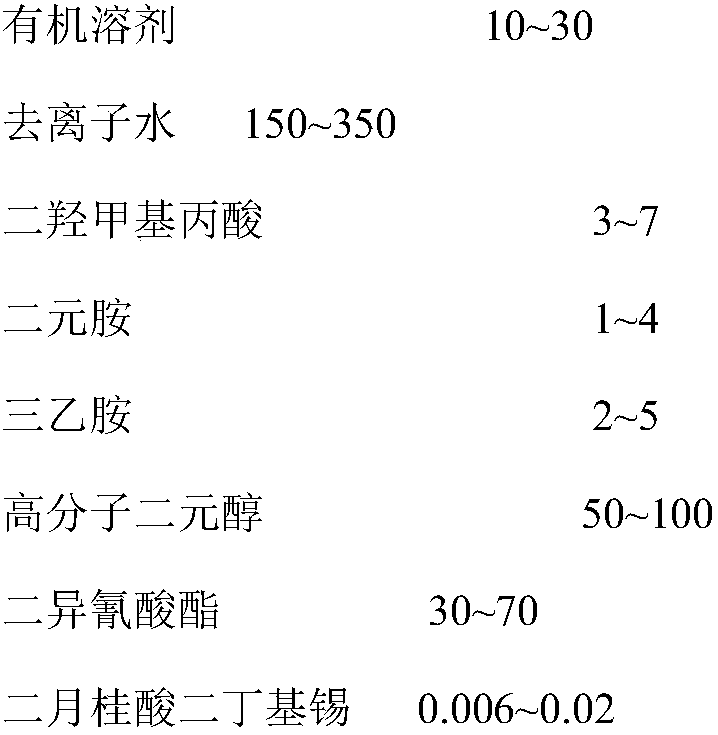

Method used

Image

Examples

Embodiment 1

[0038] Example 1: At 110°C, use a rotary distillation device to distill PEG-1000 under reduced pressure for 4 hours under a vacuum of 0.09MPa to remove moisture; Dimethylolpropionic acid was distilled under reduced pressure for 3 hours to remove moisture; 0.89g of 2-amino-4-hydroxy-6-methylpyrimidine and 1.52g of IPDI were added to the reaction vessel and reacted at 120°C 16 hours, then add 20ml of n-pentane to precipitate the product, then filter the precipitate with a sand core funnel, and wash it three times with n-pentane, bake the product in a vacuum oven at 40°C and 0.09MPa for 2 hours and evaporate the solvent to dryness , to obtain 1.28g of methylcytosine powder with isocyanate groups, that is, UPy-NCO; at 30°C, 1.28g of UPy-NCO and 0.71g of 2-amino-2-methyl-1,3-propanediol were refluxed in 30ml of chloroform After reacting for 5 hours, the product was centrifuged with a centrifuge at 10,000r / min, and the precipitated part was evaporated to dryness at 40°C and 0.09MPa ...

Embodiment 2

[0039] Example 2: At 120°C, use a rotary distillation device to distill PPG-1000 under reduced pressure for 3 hours under a vacuum of 0.09MPa to remove moisture; Dimethylolpropionic acid was distilled under reduced pressure for 3 hours to remove moisture; 0.49g of 2-amino-4-hydroxy-6-methylpyrimidine and 0.77g of IPDI were added to the reaction vessel and reacted at 100°C After 20 hours, 15ml of n-pentane was added to precipitate the product, and then the precipitate was filtered out with a sand core funnel and washed three times with n-pentane, and the product was baked in a vacuum oven at 40°C and 0.09MPa for 2 hours and evaporated to dryness , to obtain 0.73g of methylcytosine powder with isocyanate groups, that is, UPy-NCO; at 25°C, 0.73g of UPy-NCO and 0.36g of 2-amino-2-methyl-1,3-propanediol were refluxed in 30ml of chloroform After reacting for 4 hours, the product was centrifuged with a centrifuge at 10,000r / min, and the precipitated part was evaporated to dryness at ...

Embodiment 3

[0040] Example 3: At 120°C, use a rotary distillation device to distill PTMEG-1000 under reduced pressure for 2 hours under a vacuum of 0.09MPa to remove moisture; Dimethylolpropionic acid was distilled under reduced pressure for 3 hours to remove moisture; 0.90 g of 2-amino-4-hydroxy-6-methylpyrimidine and 1.61 g of IPDI were added to the reaction vessel and reacted at 120°C 16 hours, then add 25ml of n-pentane to precipitate the product, then use a sand core funnel to filter out the precipitate, and wash it three times with n-pentane, bake the product in a vacuum oven at 50°C and 0.09MPa for 3 hours and evaporate the solvent to dryness , to obtain 2.27g of methylcytosine powder with isocyanate groups, namely UPy-NCO; at 25°C, 1.27g of UPy-NCO and 0.31g of 2-amino-2-methyl-1,3-propanediol in 30ml of chloroform Reflux reaction for 6 hours, after the product was centrifuged at 10000r / min with a centrifuge, the precipitated part was evaporated to dryness at 40°C and 0.09MPa to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com