Preparation method of low-expansibility high-thermal-conductivity carbon composite material

A carbon composite material and high thermal conductivity technology, which is applied in heat exchange materials, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as expansion and volume stability changes, and achieve the effect of reducing expansion performance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

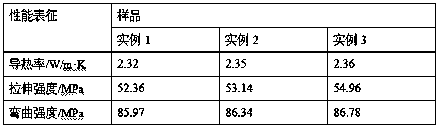

example 1

[0019] According to the mass ratio of 1:5, polyimide resin was added to N,N-dimethylacetamide to obtain a mixed solution, which was stirred and mixed at 45°C for 25 minutes, and then N,N-dimethylacetamide was added dropwise. Amide until the solid content of the mixed liquid is 45%, to obtain a dilution; by weight parts, weigh 45 parts of deionized water, 10 parts of aluminum chloride, 3 parts of 200 mesh metal aluminum powder and 1 part of yttrium oxide in a beaker , stirred and mixed and heated in a water bath at 75°C for 25 minutes, left to cool to room temperature and collected the gel solution, and the gel solution was rotary evaporated at 55°C to 1 / 5 of the volume of the gel solution, and then concentrated Gel solution, according to the volume ratio of 1:1, the concentrated gel solution and the diluent are stirred and mixed and placed in an electrospinning device, the positive and negative electrode voltages are controlled to 30kV, the receiving distance is 15cm, and the n...

example 2

[0021] According to the mass ratio of 1:5, polyimide resin was added to N,N-dimethylacetamide to obtain a mixed solution, which was stirred and mixed at 47°C for 27 minutes, and then N,N-dimethylacetamide was added dropwise. Amide until the solid content of the mixed liquid is 45%, to obtain a dilution; by weight parts, weigh 47 parts of deionized water, 12 parts of aluminum chloride, 4 parts of 200 mesh metal aluminum powder and 2 parts of yttrium oxide in a beaker , stirred and mixed and heated in a water bath at 77°C for 27 minutes, left to cool to room temperature and collected the gel liquid, and the gel liquid was rotary evaporated at 60°C to 1 / 5 of the volume of the gel liquid, and then concentrated Gel solution, according to the volume ratio of 1:1, the concentrated gel solution and the diluent are stirred and mixed and placed in an electrospinning device, the positive and negative electrode voltages are controlled to 30kV, the receiving distance is 17cm, and the nozzle...

example 3

[0023] According to the mass ratio of 1:5, polyimide resin was added to N,N-dimethylacetamide to obtain a mixed solution, which was stirred and mixed at 50°C for 30 minutes, and then N,N-dimethylacetamide was added dropwise. Amide until the solid content of the mixed liquid is 45%, to obtain a diluent; in parts by weight, weigh 50 parts of deionized water, 15 parts of aluminum chloride, 5 parts of 200 mesh metal aluminum powder and 2 parts of yttrium oxide in a beaker , stirred and mixed, heated in a water bath at 80°C for 30 minutes, allowed to stand and cooled to room temperature and collected the gel solution, and the gel solution was rotary evaporated at 65°C to 1 / 5 of the volume of the gel solution, and then concentrated Gel solution, according to the volume ratio of 1:1, the concentrated gel solution and the diluent are stirred and mixed and placed in an electrospinning device, the positive and negative electrode voltages are controlled to 30kV, the receiving distance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com