Soaping agent and soaping technology

A soaping agent and soaping technology, applied in the field of soaping agent and soaping technology, can solve the problems of large water consumption, high processing energy consumption, increased waste water treatment burden, etc., and achieve easy washing, enhanced activity, good The effect of bleaching power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

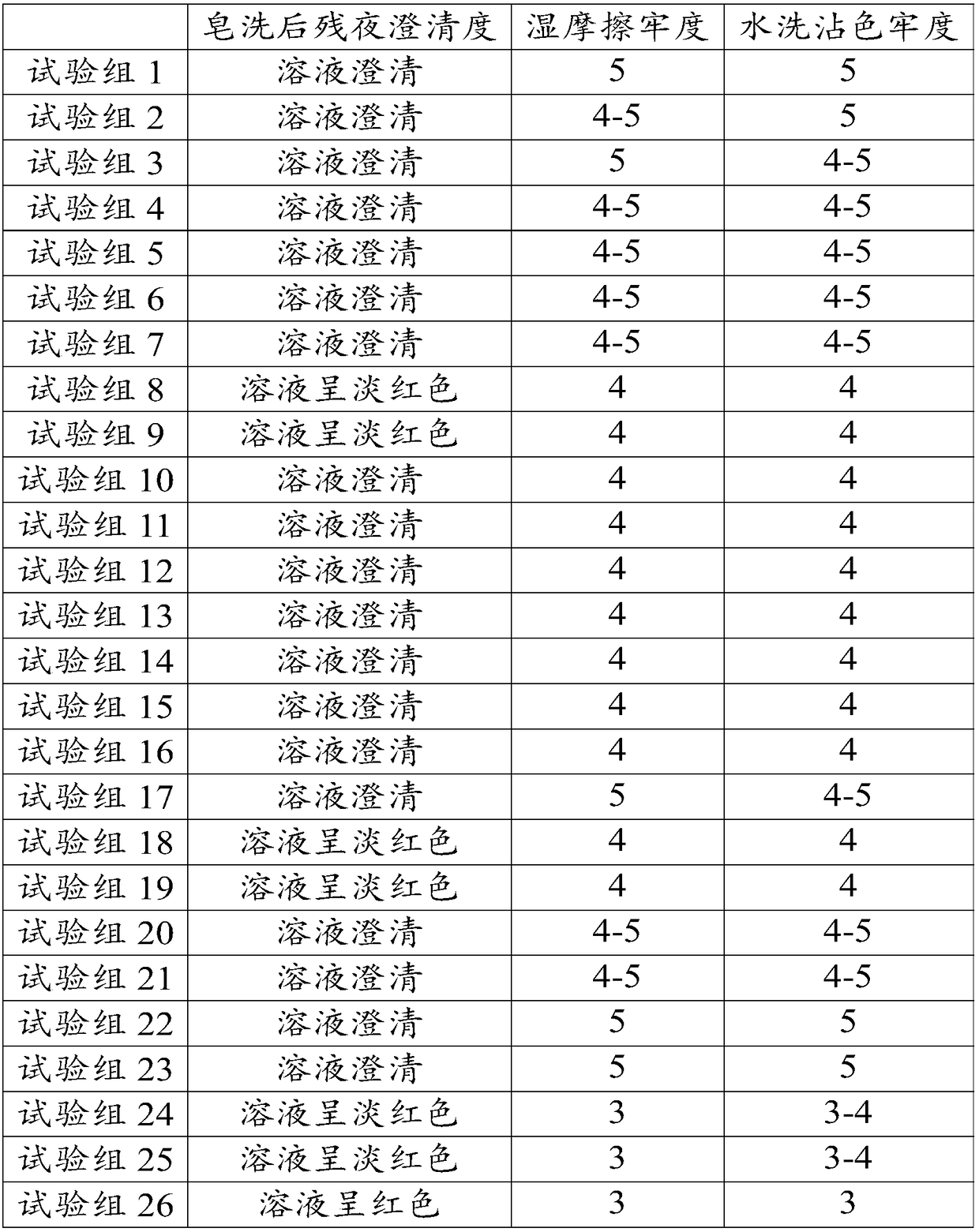

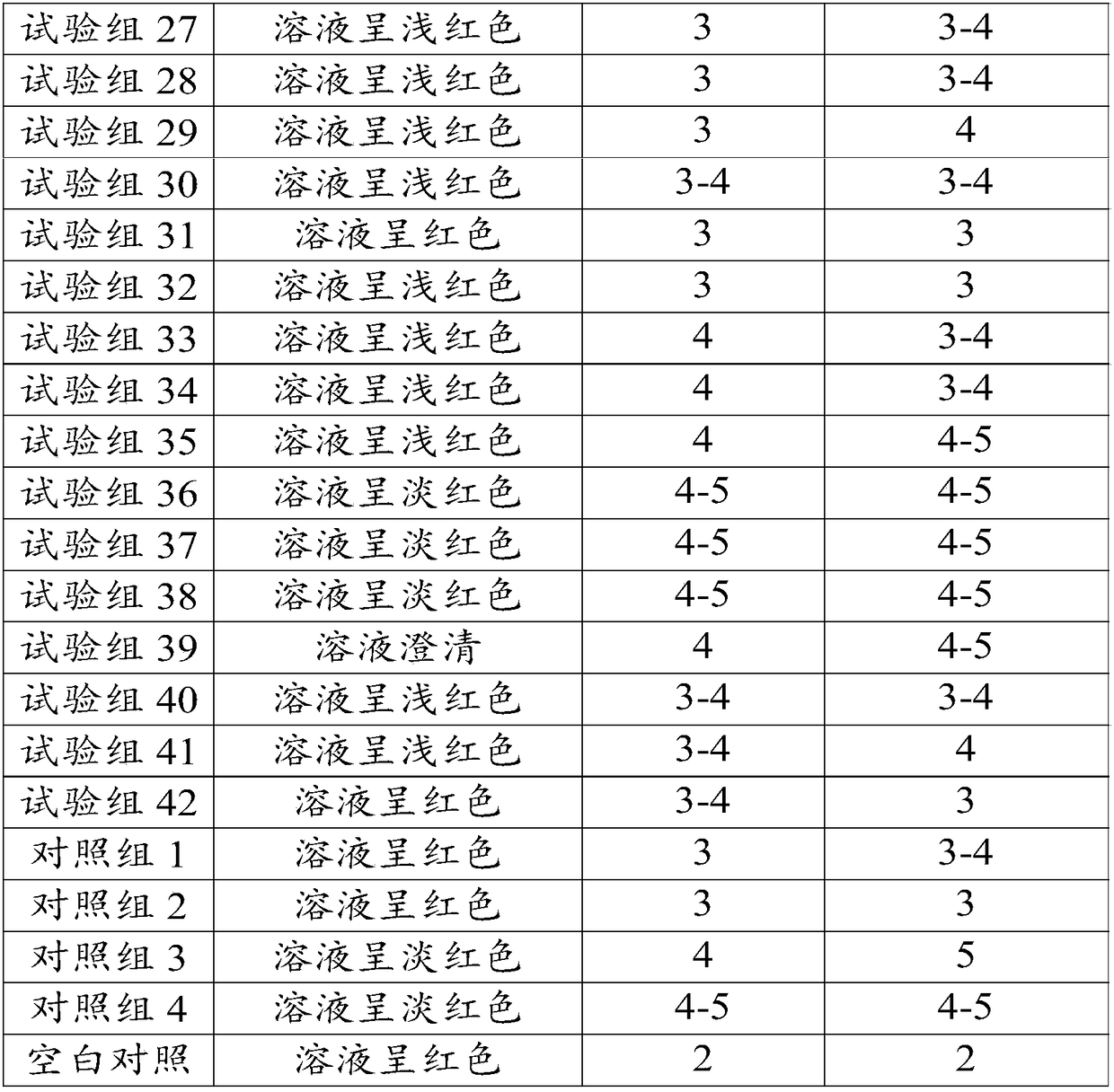

Examples

Embodiment 1

[0071] The present embodiment provides a soaping agent, comprising the following components in parts by weight: 12 parts of immobilized laccase, 20 parts of laccase mediator, 2.5 parts of horseradish peroxidase, 4.5 parts of lipase, spit 1.2 parts of Wen-80, 0.5 parts of sodium lauryl sulfate, 0.7 parts of sodium dodecylbenzenesulfonate, 0.3 parts of sodium carbonate, 0.3 parts of sodium bicarbonate, 0.5 parts of sodium citrate, 0.3 parts of sodium tripolyphosphate, 0.65 parts of calcium chloride, 0.7 parts of sodium sulfate and 6.65 parts of horse-propylene copolymer;

[0072] Among them, the carrier of immobilized laccase is mesoporous SiO 2 / Fe 3 o 4 Hollow magnetic microspheres;

[0073] Wherein, the laccase mediator is sinapinic acid and acetylacetone, and the mass ratio of sinapinic acid and acetylacetone is 3.5:1.

Embodiment 2

[0075] This embodiment provides a kind of soaping agent, and the difference with embodiment 1 is, the carrier of the immobilized laccase of this soaping agent is magnetic chitosan microsphere.

Embodiment 3

[0077] This embodiment provides a soaping agent, the difference from Example 1 is that the carrier of the soaping agent for immobilizing laccase is epoxidized polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com