A metal-organic framework-supported phosphotungstic acid catalyst, preparation method and application of catalytic synthesis of adipic acid

A metal-organic framework, phosphotungstic acid technology, used in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem that the active component phosphotungstic acid cannot effectively Dispersion, difficult catalyst recycling, complex catalyst preparation process, etc., to achieve the effect of recyclable preparation process, green and clean production process, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

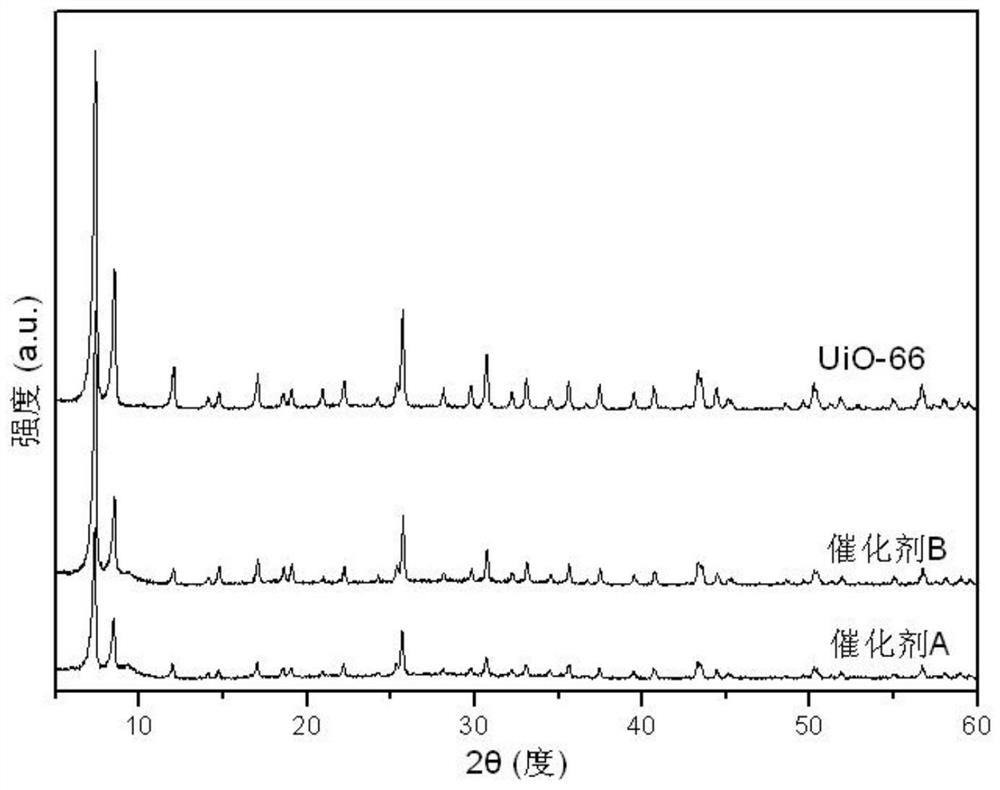

[0024] (1) Preparation of metal-organic framework-supported phosphotungstic acid catalyst

[0025] According to method A, add 1.6g of metal-organic framework UiO-66 and 100mL of anhydrous n-hexane into the round bottom flask, ultrasonically disperse for 30min, and add 686μL of phosphotungstic acid aqueous solution with a concentration of 1g / mL dropwise under rapid stirring (that is, metal The mass ratio of organic framework to phosphotungstic acid is 2.3:1), continue to stir for 8 hours, and filter with suction. The obtained solid is vacuum-dried at 120°C for 10 hours, and the metal-organic framework-supported phosphotungstic acid catalyst is prepared, which is marked as catalyst A.

[0026] (2) Synthesis of adipic acid

[0027] Add 0.5g of catalyst A, 0.056g of oxalic acid (0.62mmol) and 15.9mL of 30% hydrogen peroxide (155mmol) into the round bottom flask, stir well and then add 3g of cyclohexanone (31mmol), and stir at 90°C After reacting for 8 hours, the reacted mixture w...

Embodiment 2

[0029] The operation steps are the same as in Example 1, except that 3.1 g of cyclohexanol (31 mmol) is added to replace cyclohexanone during the synthesis of adipic acid, and the yield of adipic acid is 72.90%.

Embodiment 3

[0031] The operation steps are the same as in Example 1, the difference is that the amount of oxalic acid added is 0 when adipic acid is synthesized, and the yield of adipic acid is 61.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com