Lithium tantalate narrow-band gas detector and preparation method thereof

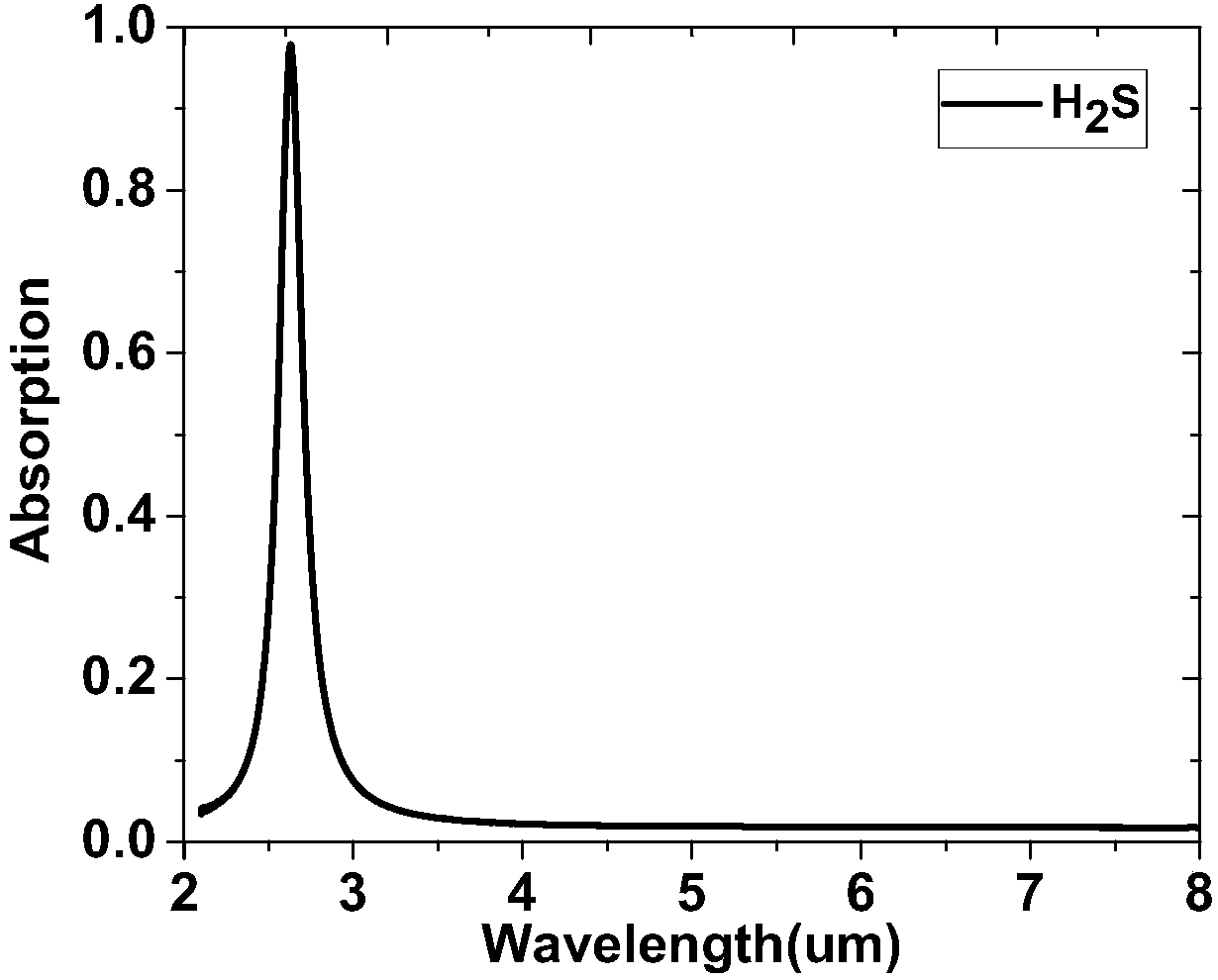

A gas detector, lithium tantalate technology, applied in the field of gas detection, can solve the problems of high cost, difficult packaging, no wavelength selectivity, etc., and achieve the effect of low cost, high absorption and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

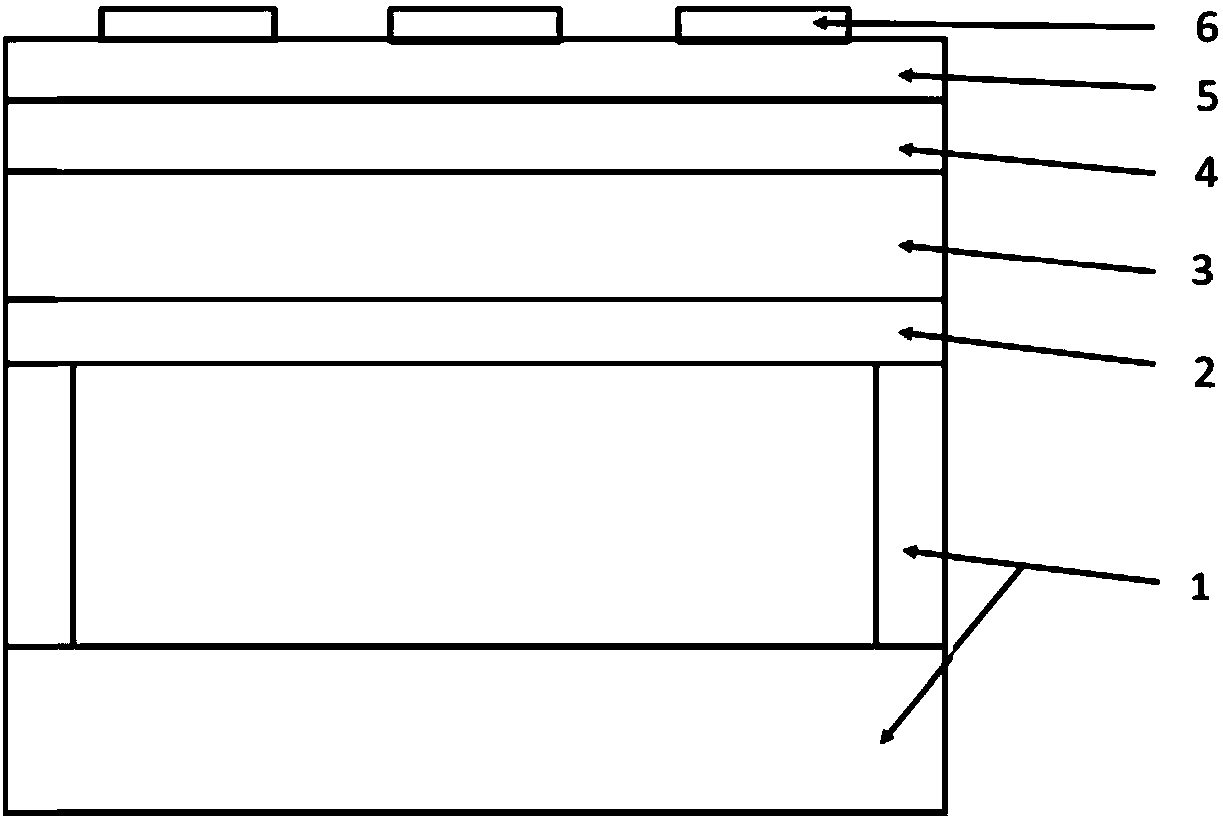

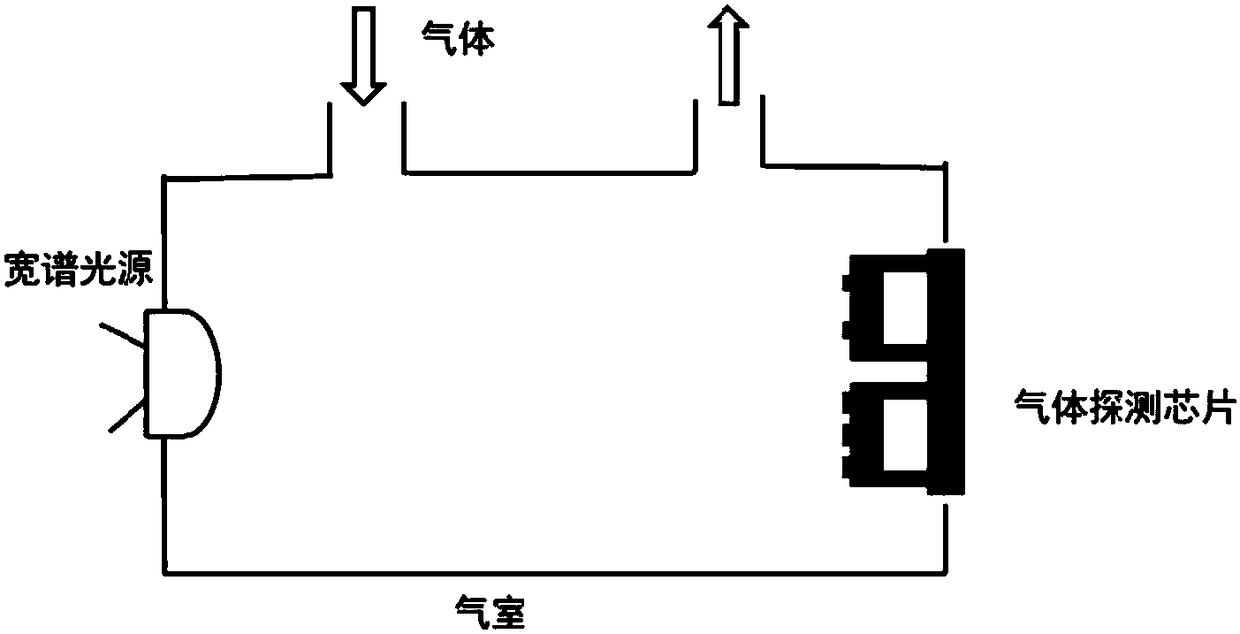

Embodiment 1

[0038] Electron beam evaporation was used to grow a gold back plate and a lower electrode on the upper surface and lower surface of a lithium tantalate wafer respectively, and a dielectric layer was grown on the upper surface of the gold back plate by magnetron sputtering; a PMMA positive electrode was spin-coated on the upper surface of the dielectric layer. Glue, the speed of spin coating is 1500rpm, dry at 150 ℃ for 2min, then carry out exposure and development treatment successively, the electric current of described exposure is 2nA, obtain the photoresist layer with disc structure, in the photoresist layer A layer of gold was grown by electron beam evaporation, and then peeled off with acetone to obtain an antenna array. Then, the lower electrode was fixed on the silicon base with four quarter silicon pillars and packaged to obtain a lithium tantalate narrow-band gas detector.

[0039] Wherein, the antenna in the antenna array is a disc gold antenna, the diameter of the di...

Embodiment 2

[0041] Use magnetron sputtering to grow a gold back plate and a lower electrode on the upper surface and lower surface of a lithium tantalate wafer, and use chemical vapor deposition to grow a dielectric layer on the upper surface of the gold back plate; spin-coat PMMA on the upper surface of the dielectric layer. Glue, the speed of spin coating is 2500rpm, dry at 100 ℃ for 4min, then carry out exposure and development treatment successively, the electric current of described exposure is 4nA, obtain the photoresist layer with the disc structure, in the photoresist layer A layer of gold is grown by electron beam evaporation, and then peeled off with isopropanol to obtain an antenna array. Then, the lower electrode is fixed on the silicon base with four quarter silicon pillars and packaged to obtain a lithium tantalate narrow-band gas detection. device.

[0042] Wherein, the diameter of the disk gold antenna is 940nm, the thickness of the disk gold antenna is 50nm, the distance ...

Embodiment 3

[0044] Use magnetron sputtering to grow a gold back plate and a lower electrode on the upper surface and lower surface of a lithium tantalate wafer, and use chemical vapor deposition to grow a dielectric layer on the upper surface of the gold back plate; spin-coat PMMA on the upper surface of the dielectric layer. The speed of spin coating is 2000rpm, and it is dried at 120°C for 3min, and then exposure and development are performed sequentially. The current of the exposure is 3nA, and a photoresist layer with a disc structure is obtained. A layer of gold is grown by electron beam evaporation and stripped with deionized water to obtain an antenna array, and then the lower electrode is fixed on the silicon base with four quarter silicon pillars and packaged to obtain a lithium tantalate narrow-band gas detection device.

[0045] Wherein, the diameter of the disk gold antenna is 1290nm, the thickness of the disk gold antenna is 50nm, the distance between the centers of two adjac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com