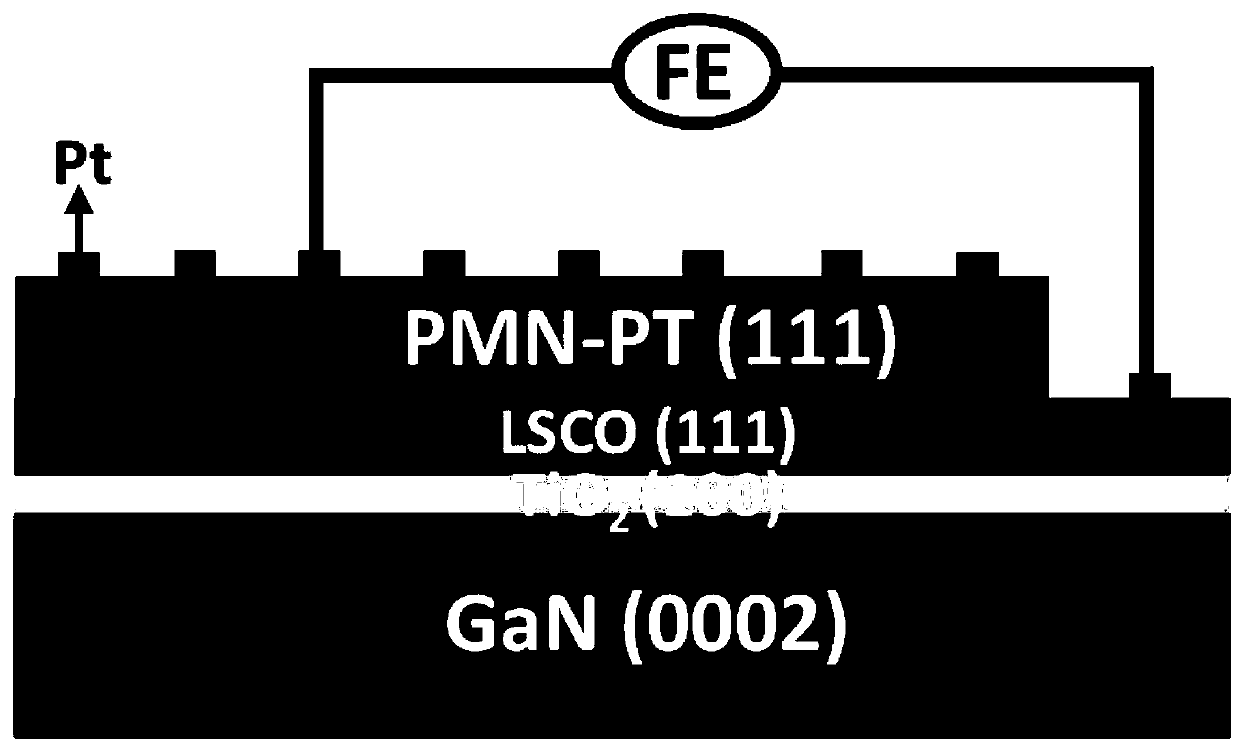

Titanium niobate lead magnesium oxide ferroelectric thin film GaN-based epitaxial integration and its preparation method

A technology of titanium lead magnesium niobate and ferroelectric thin film, which is applied in the direction of circuits, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems that limit the practical application of GaN-based integrated ferroelectric devices and unfavorable epitaxial substrates. Electrode growth, complex structure and other issues, to achieve the effect of simple structure, reduced lattice mismatch and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

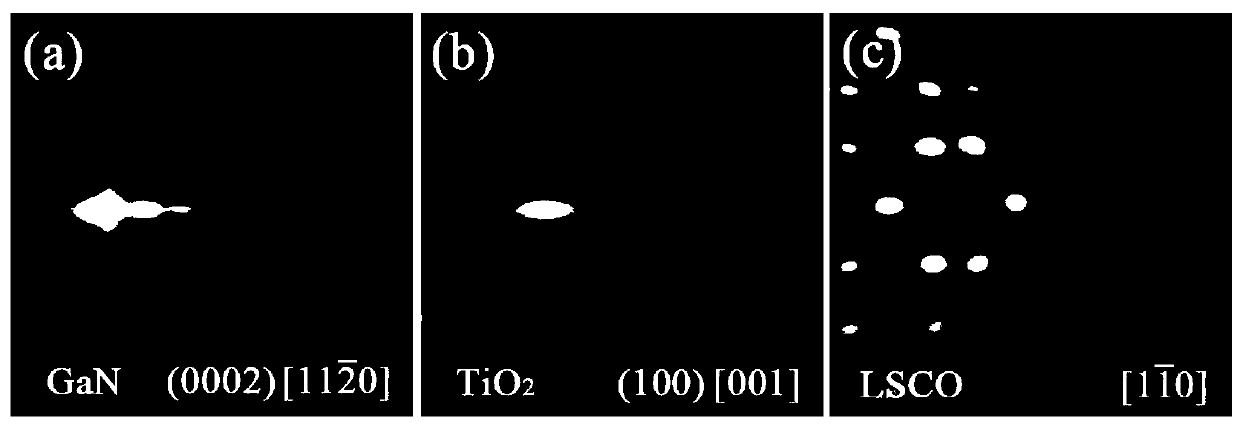

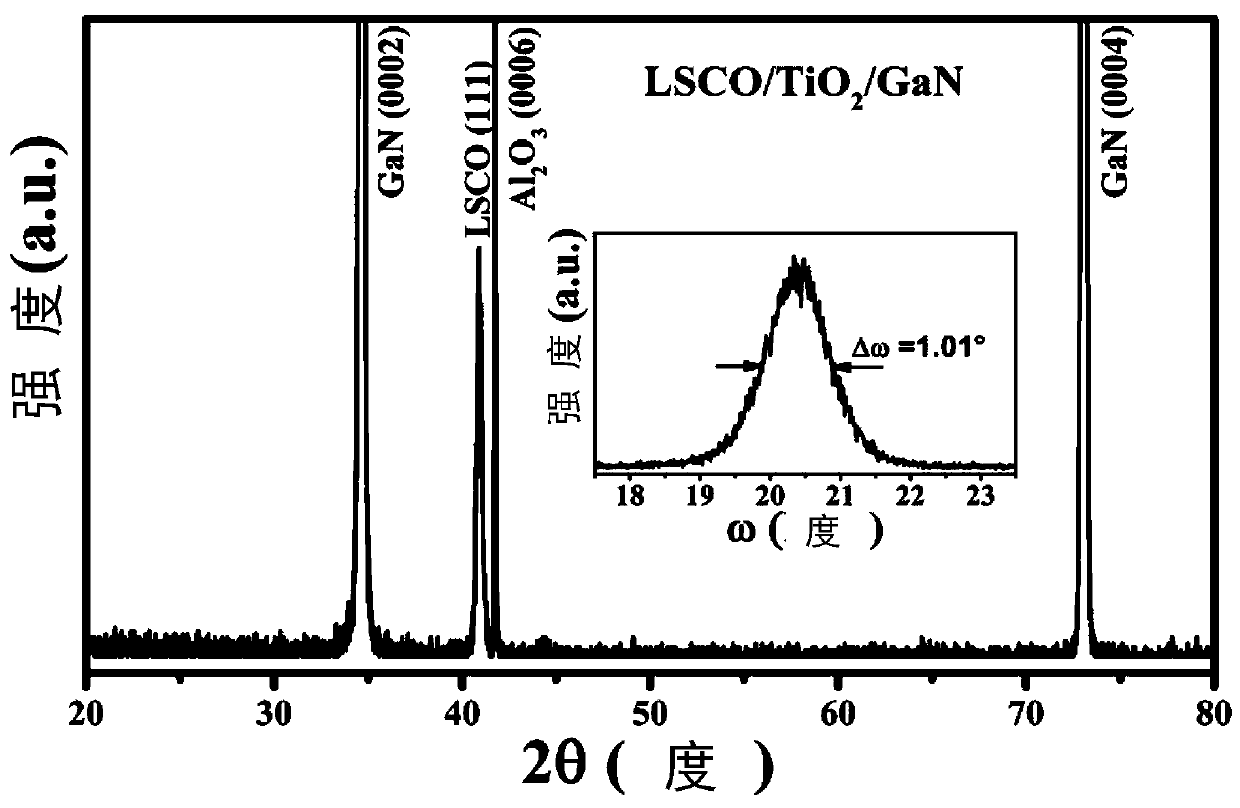

[0044] GaN semiconductor substrate cleaning. The selected substrate is sapphire-based epitaxial wafer GaN(0002) / Al2O3. The substrate was ultrasonically cleaned in acetone, ethanol and water for 8 minutes, then immersed in a hydrochloric acid solution with a concentration of 1.8 mol / L for 3 minutes, finally placed in deionized water for 8 minutes, and dried with nitrogen ;

[0045] TiO 2 Buffer layer preparation. The present invention uses TiO 2 The ceramic block is used as the target material. Firstly, vacuum the backside of the thin film deposition system to ≤2×10 -4 Pa, the substrate was heated to 550°C at a heating rate of 5°C / min. Growth of TiO by pulsed laser deposition technique 2 The parameters of the film include: deposition temperature: 550°C; deposition oxygen pressure: 1×10 -3 Pa; laser energy density: 1J / cm 2 ; Deposition rate: 0.5nm / min. Deposited TiO 2 The film thickness is 2nm;

[0046] LSCO buffer layer preparation. The present invention uses La 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com