Antibacterial hollow fiber membrane, preparation method and applications thereof

A fiber membrane and hollow technology, applied in the field of antibacterial hollow fiber membrane and its preparation, can solve the problems of loss of antibacterial substances, decline in antibacterial performance, unstable fixation, etc., and achieve high water flux, high antibacterial performance, and strong binding ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] One aspect of the present invention provides a method for preparing an antibacterial hollow fiber membrane, the method comprising:

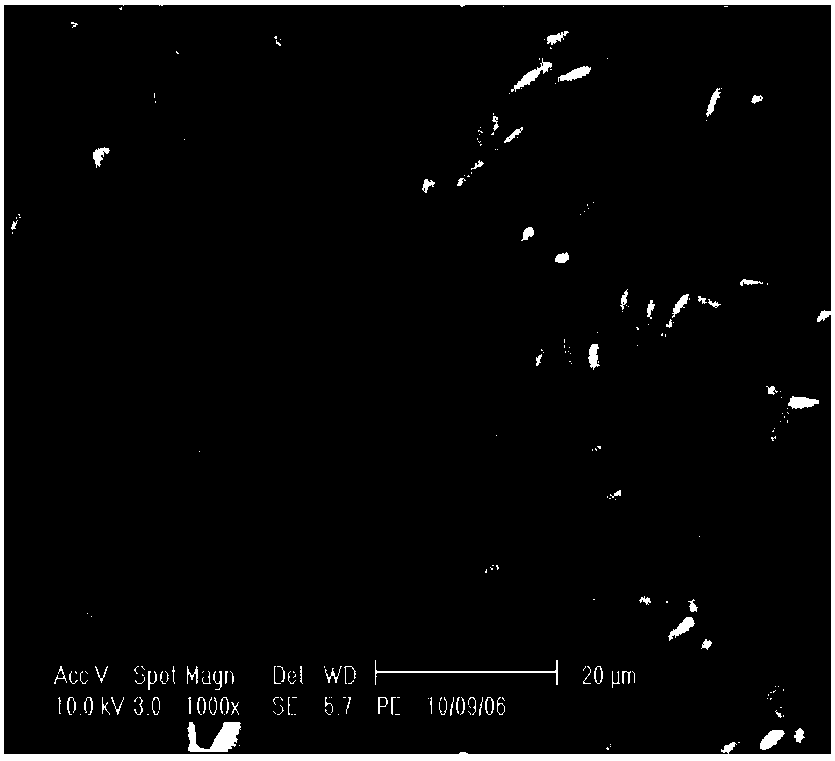

[0054] (1) In an alkaline solution, activate the fibers mixed with silver filaments to obtain activated fibers;

[0055] (2) mixing the activated fiber filaments with the membrane-making solution, and braiding the resulting mixture to obtain a hollow fiber braided tube;

[0056] (3) forming the hollow fiber braided tube into an antibacterial hollow fiber membrane;

[0057] Wherein, the film-forming solution contains a film-forming polymer, a porogen and additive A; the additive A is one or more of polyols and polypolyols with a number average molecular weight less than 1,000.

[0058] According to the present invention, the present invention can make the silver thread stably exist in the antibacterial hollow fiber membrane by combining the silver thread with the film-forming fiber thread and adopting the additive A in the film-making solu...

Embodiment approach

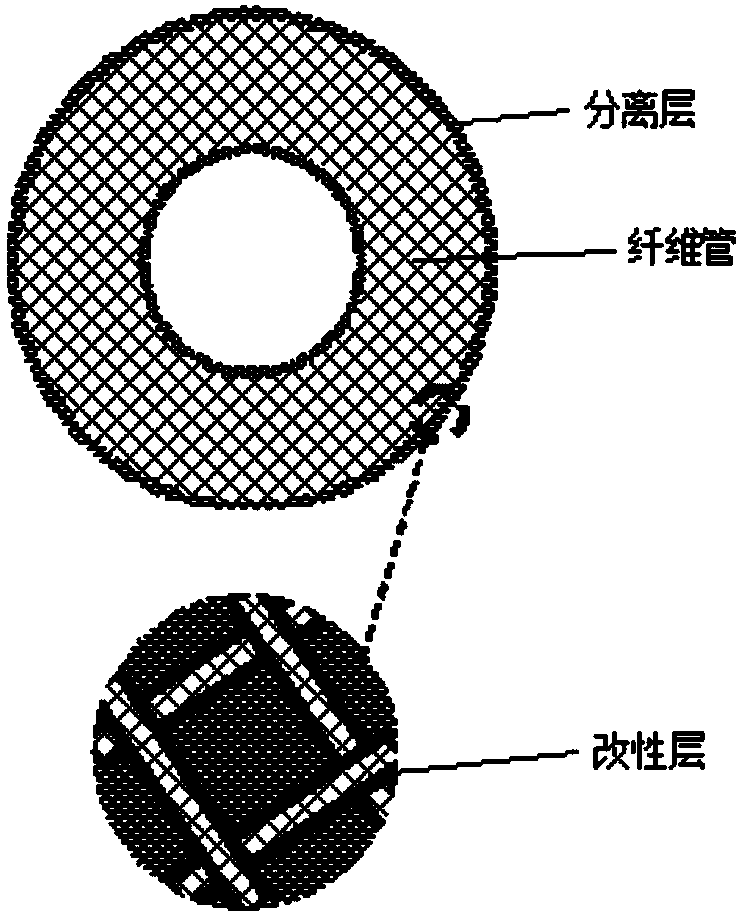

[0156] According to a preferred embodiment of the present invention, the weaving is: the silver-containing fiber bundle and the polymer fiber bundle are cross-braided in a "herringbone" shape along the core liquid tube.

[0157] Preferably, the polymer fiber bundle is composed of 100-1000 fiber filaments. Preferably, the silver-containing fiber bundle is composed of 1-10 silver-containing fiber filaments.

[0158] According to the present invention, the silver-containing fiber bundles can be obtained commercially or by self-made.

[0159] According to a preferred embodiment of the present invention, the fiber filaments are selected from at least one of polyester fibers, polyamide fibers, polyolefin fibers, polyamide fibers, polyurethane fibers, polysulfone fibers or glass fibers, preferably polyester fibers and / or or polyamide fibers.

[0160] According to a preferred embodiment of the present invention, the casting solution used in step 2) includes polyvinylidene fluoride, ...

preparation example 1-9

[0185] Under the protection of nitrogen, according to the composition in Table 1 (the type of each compound and the concentration in the membrane-forming solution are as listed, wherein, the concentration refers to the percentage of the net mass of each compound accounting for the total weight of the membrane-forming solution), each group Stir and mix under specified conditions (conditions are shown in Table 1) to dissolve, then vacuum degassing to obtain the corresponding film-making solution; in Table 1:

[0186] PVDF is polyvinylidene fluoride purchased from Arkema MG15 brand, and its number average molecular weight is 210,000;

[0187] PVP is polyvinylpyrrolidone purchased from Sinopharm Reagent Co., Ltd. K30 brand, and its number average molecular weight is 30,000;

[0188] PEG20,000 is polyethylene glycol purchased from Sinopharm Reagent Co., Ltd., and its number average molecular weight is 20,000;

[0189] PEG400 is polyethylene glycol purchased from Sinopharm Reagent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com