Method for directly preparing samarium-iron alloy powder through spray pyrolysis reduction method

A spray thermal decomposition, samarium iron alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of affecting the alloying process, operation difficulties, magnetic properties decline, etc., to achieve good flow processability, uniform mixing and dispersion, reducing The effect of samarium volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

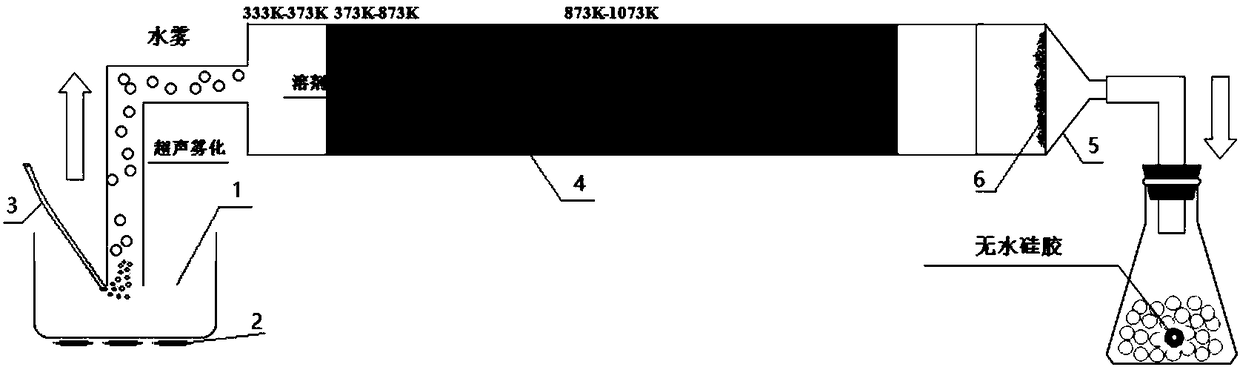

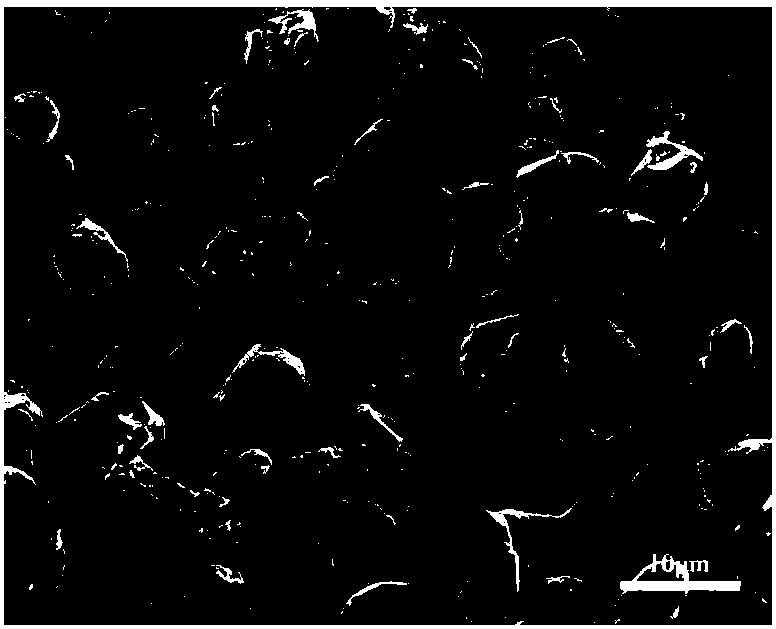

[0041] Take 0.4mol / L of SmCl 3 Solution 26mL (0.0104mol) and 0.4mol / L FeCl 3 Solution 170mL (0.06mol) mixed and poured into figure 1 For the ultrasonic atomizer shown, the tube furnace is heated to a central temperature of 800°C, and the heating rate is 10°C / min (in the temperature range of 50-400°C) and 8L / min (in the temperature range of 400-800°C) , and then turn on the atomizer, the frequency of the ultrasonic atomizer is 1.5MHz; tighten the pressure reducing valve of the nitrogen tank, set the gas flow rate to 3L / min through the gas flow meter, and carry the gas N 2 Transport the atomized water mist to the tube furnace; after reacting for 3-6 hours, close the ultrasonic atomizer, reduce the gas flow rate to 0.5L / min, wait for the temperature in the furnace to cool down to room temperature, and then close it. The spray decomposition products are collected in the collector, such as figure 2 shown. After weighing 1.5g of the collected oxide powder, spread it into a smal...

Embodiment 2

[0043] Take 0.4mol / L of Sm(NO 3 ) 3 Solution 24mL and 0.4mol / L Fe(NO 3 ) 3 Solution 180mL mixed and poured figure 1 For the ultrasonic atomizer shown, heat the tube furnace to 800°C with a heating rate of 10°C / min (in the temperature range of 50-400°C) and 8L / min (in the temperature range of 400-800°C), and then Turn on the atomizer, the frequency of the ultrasonic atomizer is 1.5MHz; tighten the pressure reducing valve of the nitrogen tank, set the gas flow rate to 3L / min through the gas flow meter, and carry the gas N 2 Transport the atomized water mist to the tube furnace; after reacting for 3-6 hours, close the ultrasonic atomizer, reduce the gas flow rate to 0.5L / min, wait for the temperature in the furnace to cool down to room temperature, and then close it. The products of spray decomposition are collected in the collector. After weighing 1.5g of the collected oxide powder, spread it into a small porcelain boat, and then add 0.5g of metal Ca particles and 0.18g of ...

Embodiment 3

[0045] Take 0.4mol / L of Sm 2 (SO 4 ) 3 Solution 25mL and 0.4mol / L FeSO 4 Solution 170mL mixed and poured figure 1 For the ultrasonic atomizer shown, the tube furnace is heated to a central temperature of 850°C, and the heating rate is 10°C / min (in the temperature range of 50-400°C) and 8L / min (in the temperature range of 400-800°C) , and then turn on the atomizer, the frequency of the ultrasonic atomizer is 2.4MHz; tighten the pressure reducing valve of the nitrogen tank, set the gas flow rate to 2L / min through the gas flow meter, and carry the gas N 2 Transport the atomized water mist to the tube furnace; after reacting for 3-6 hours, close the ultrasonic atomizer, reduce the gas flow rate to 0.5L / min, wait for the temperature in the furnace to cool down to room temperature, and then close it. The products of spray decomposition are collected in the collector. After weighing 1.5 g of the collected oxide powder by one-step calcium reduction, add 0.8 g of metal Ca particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com